Fiberglass PVC Foam Sandwich Panel

High Strength | Closed Cells Without Voids | Lightweight | Sound and Heat Insulation

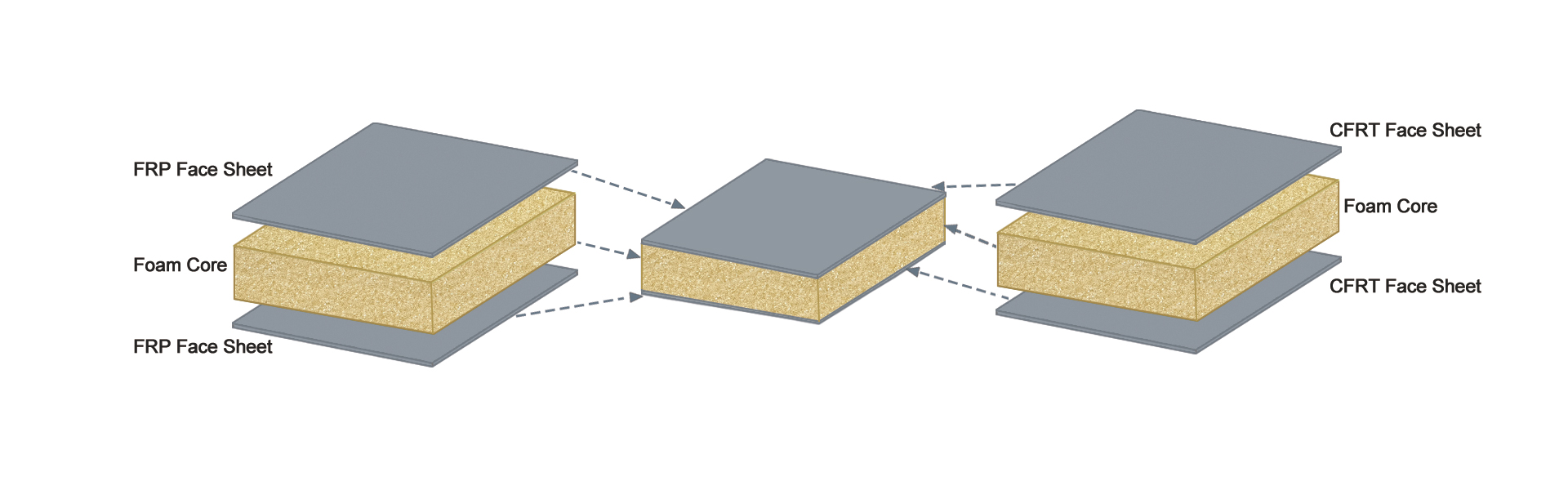

FRP skin PVC foam sandwich panel is a new type of composite material. The upper and lower layers are made of fiberglass and the middle is PVC foam core material. In addition, adhesives can be used to laminate the FRP surface with other materials, and the options for skin materials are unlimited. The stability of PVC foam combined with the high toughness of FRP makes it one of the ideal materials for lightweight solutions.

PVC foam offers a balanced combination of static and dynamic properties and has good resistance to water absorption. They also have a large operating temperature range, typically -240℃~80℃, and are resistant to many chemicals. Its fine microporous structure creates optimal density for stiffness and durability. Compared with traditional metal composite panels, fiberglass PVC foam composite panels are lighter in weight, not easily deformed, easy to install, and have a longer service life. They can be widely used in box trucks, off-road RVs, yachts, public transportation, furniture, construction and many other different fields.

Basic Specifications

| Skin Material | Thermoset FRP | Thermoplastic CFRT |

| Core Material | PVC Foam Core | |

| Skin Thickness | 0.7~5.0mm | 0.4~10mm |

| Length | ≤12m | |

| Width | ≤3.2m | |

| Surface Color | Natural, other colors can be customized | White,black,wood grain,natural |

| Surface Pattern | Glossy, matte, stone, weave, bubble, and imitation leather surface patterns | Glossy, matte |

| Process Option | Embedded reinforcement materials; CNC machining services | |

| Total Thickness | 10~120mm (Customized) | |

FRP VS CFRT

| Skin Material | FRP | CFRT |

| Rigidity | Good | Very good |

| Impact Strength | Good | Very good |

| Scratch Resistant | Good | Very good |

| Surface Smoothness | Very good | Good |

| Corrosion Resistance | Very good | Good |

| Lightweight | Good | -35% |

| Tenacity | / | Good |

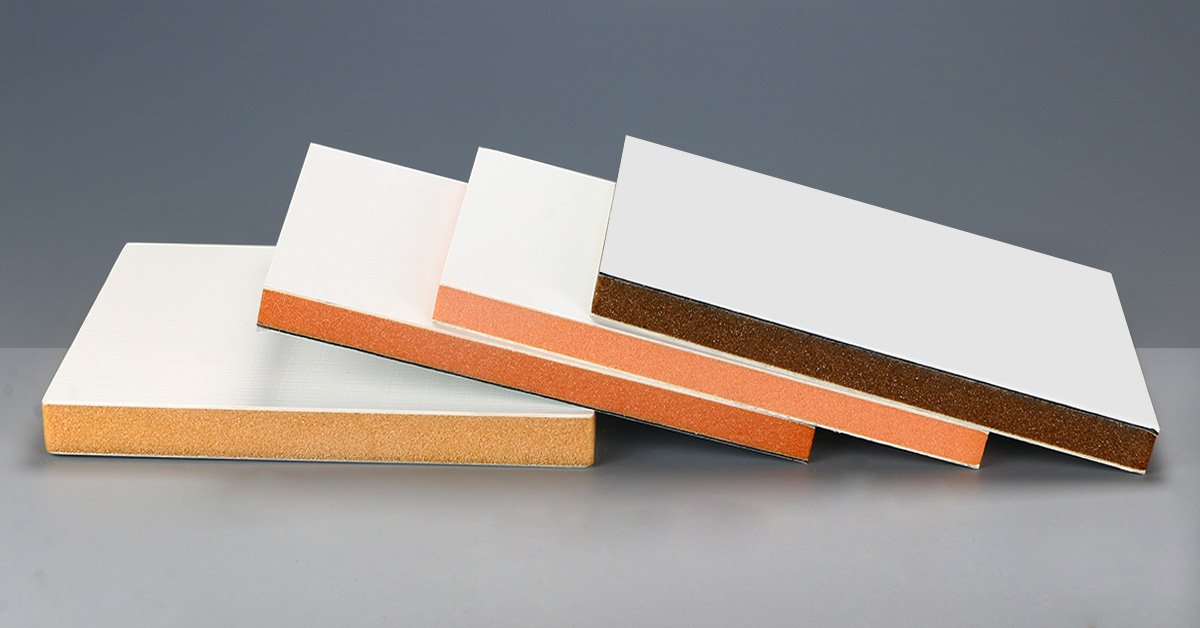

PVC Foam Core Sandwich Panel Samples

Features & Benefits

- Lightweight and High Strength: FRP/CFRT provides high-strength continuous fiber reinforcement, while the PVC foam core is lightweight and stiff, giving FRP/CFRT PVC sandwich panels an excellent strength-to-weight ratio.

- Excellent Thermal Insulation Performance: PVC foam has good thermal insulation properties while maintaining a certain strength, making this sandwich panel very popular in applications that require thermal insulation and weight reduction.

- Corrosion and Chemical Resistance: PVC has good corrosion resistance and chemical resistance, allowing FRP/CFRT PVC sandwich panels to be used in harsh environments for a long time.

- Easy Processability: It can be cut and processed as needed, has good formability, and is suitable for manufacturing various complex shapes

Technical Data

| Test Items | Test Standards | Unit | Typical Value | PVC40 | PVC48 | PVC55 | PVC75 | PVC90 | PVC130 | PVC200 | PVC250 |

| Density | ISO 845 | Kg/m3 | Average Range | 40 | 48 43-55 | 60 54-69 | 80 72-92 | 100 90-115 | 130 120-150 | 200 180-250 | 250 225-288 |

| Compression Strength | ISO 844 | N/mm2 | Average Minimum | 0.45 | 0.60 1.50 | 0.90 0.75 | 1.45 1.10 | 2.0 1.7 | 3.0 2.6 | 5.2 4.5 | 6.6 5.3 |

| Compression Modulus | DIN 53421 | N/mm2 | Average Minimum | 41 | 48 35 | 69 55 | 104 80 | 130 110 | 170 145 | 280 240 | 350 280 |