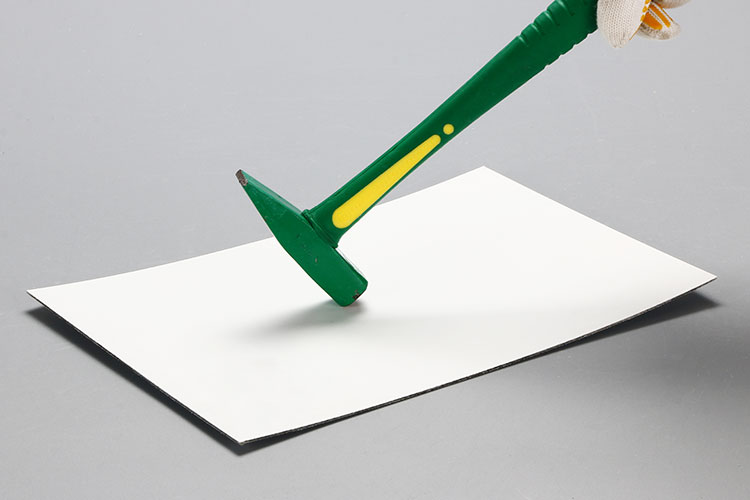

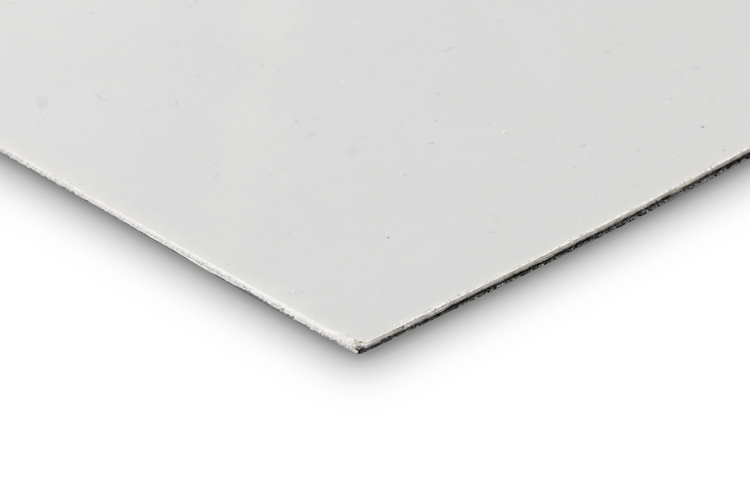

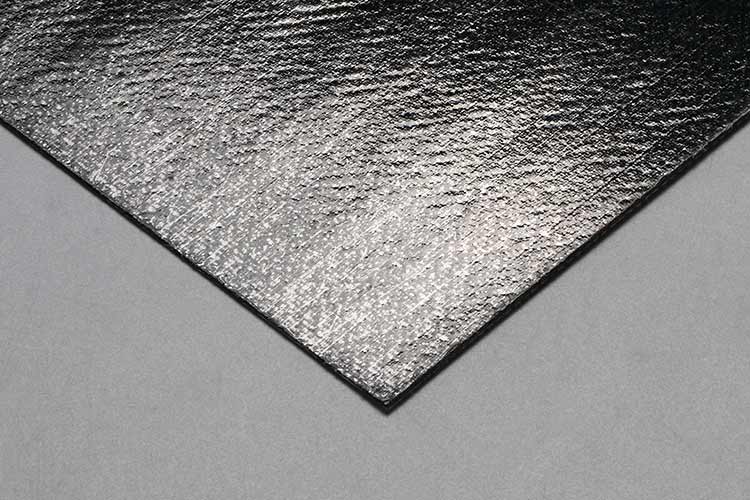

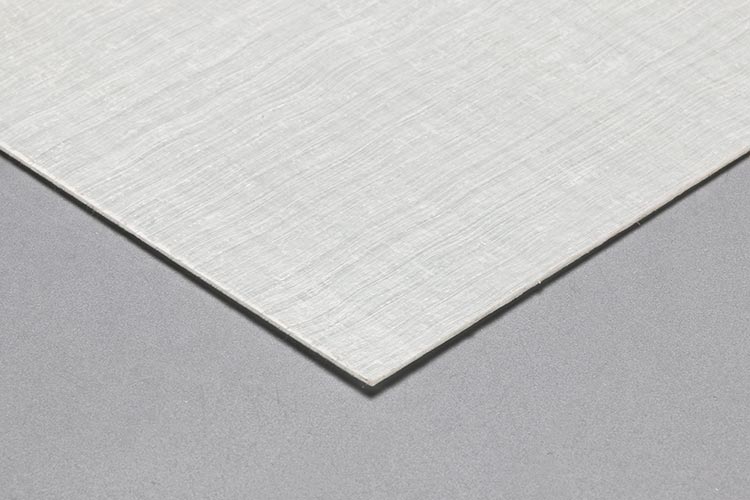

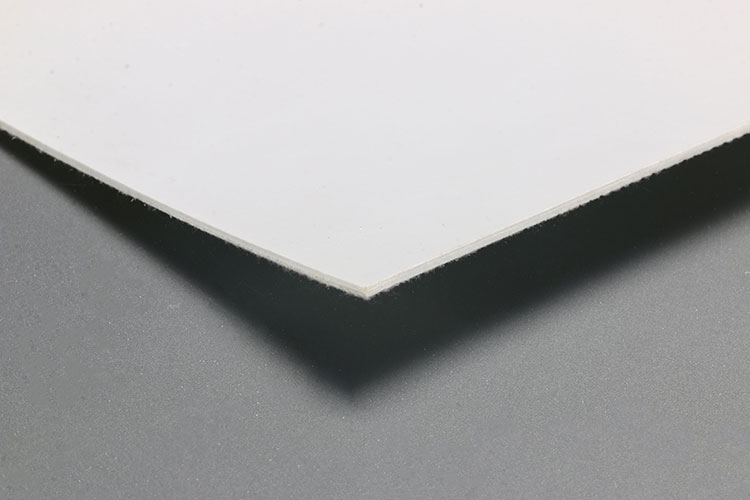

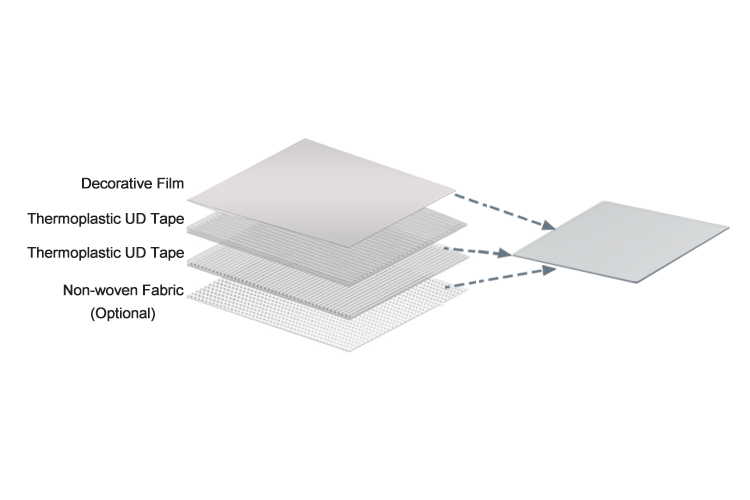

Structure of CFRT Sheet

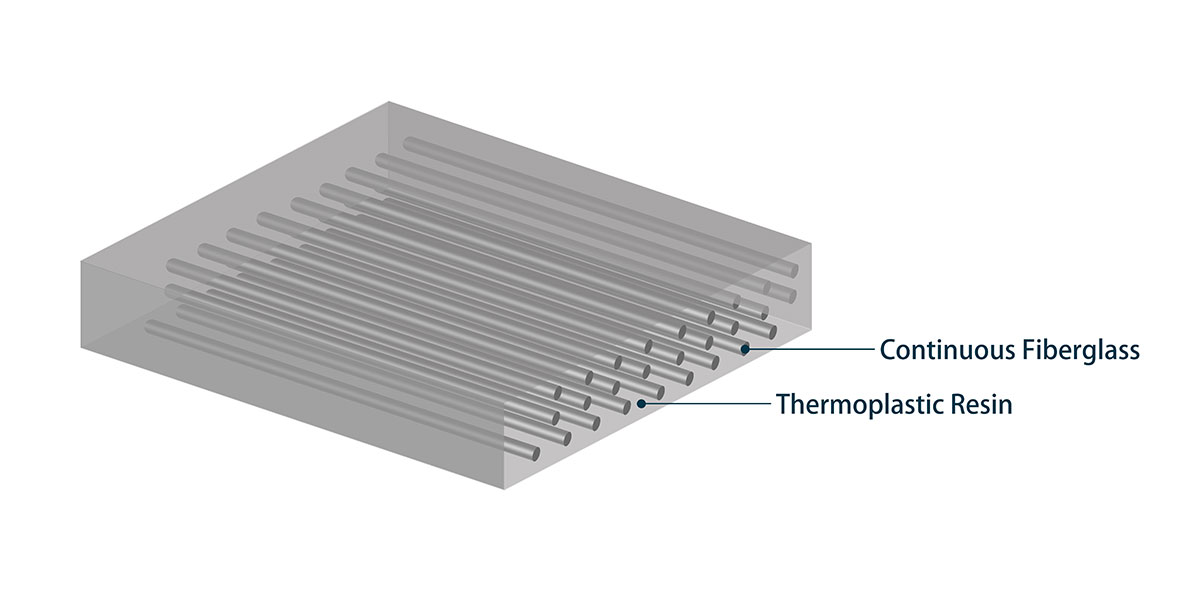

CFRT (Continuous Fiber Reinforced Thermoplastic) Sheet, is a new FRP composite material made of continuous fiber as reinforcing material and thermoplastic resin as matrix through thermal lamination process.

Decorative Film

PP/PVC/PET and other protective films can be selected,

Thermoplastic UD Tape

Layers of UD tape: 2~9 layers, the number of layers can be customized.

Fibers: Continuous fiberglass.

Resin Types: Polypropylene (PP), polyethylene (PE), nylon (PA), polyphenylene sulfide (PPS), etc.

Additives: Antioxidant, UV stabilizer, Flame retardant agent, Custom color.

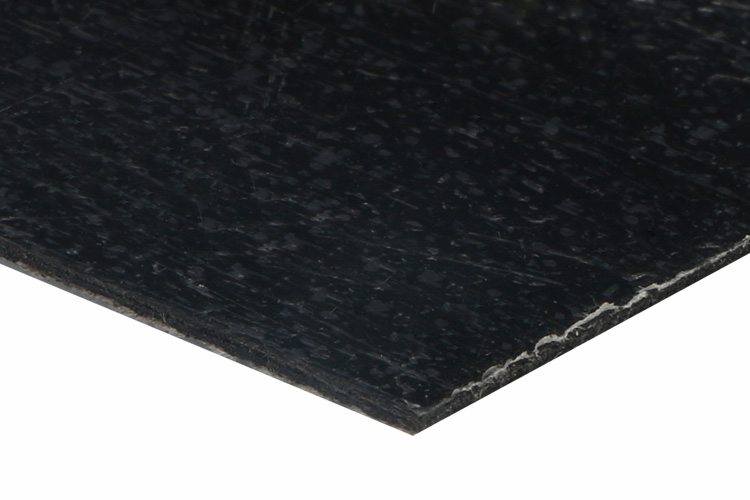

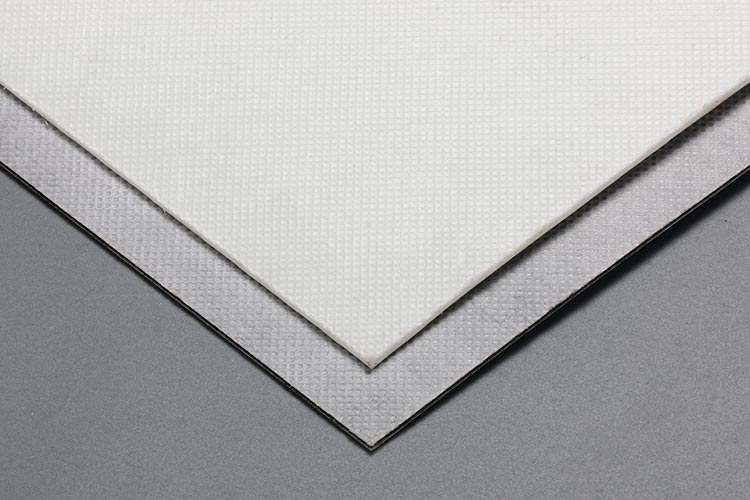

Non-woven Back

The non-woven fabric can promote the tighter adhesion of the CFRT sheet to other material systems.

Performance Parameter

| Typical Product | Density(g/cm3) | E-Glass Fiber Content | Thickness(mm) | Areal Weight(g/m2) | Tensile Strength(MPa) | Tensile Modules(GPa) | Color |

| UD-PP-300-60 | 1.5 | 60% | 0.2 | 300 | 800 | 28 | Natural or Black |

| UD-PP-370-60 | 1.5 | 60% | 0.25 | 370 | 850 | 28 | Natural or Black |

| UD-PP-450-60 | 1.5 | 60% | 0.3 | 450 | 900 | 30 | Natural or Black |

| UD-PE-450-65 | 1.6 | 65% | 0.3 | 450 | 850 | 30 | Natural or Black |

| UD-PE-500-70 | 1.7 | 70% | 0.35 | 500 | 900 | 30 | Natural or Black |

| UD-KPP-450-60 | 1.5 | 60% | 0.3 | 450 | 750 | 28 | Natural or Black |

| UD-ZRPP-450-60 | 1.5 | 60% | 0.3 | 450 | 700 | 28 | Natural or Black |

Features

The density of CFRT is only 1/4~1/5 of steel and 1/3~1/2 of aluminum.

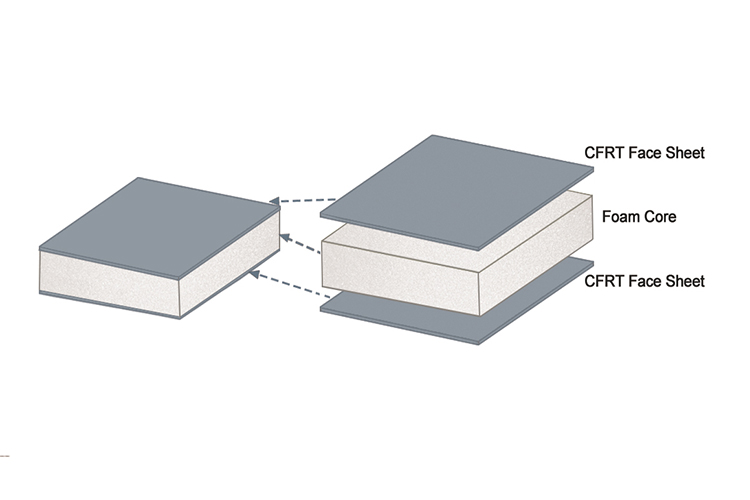

CFRT Sandwich Panels

CFRT sheets can be composited with PP honeycomb, foam (XPS/PET/PU/PVC), etc., and are used in ships, RVs, vans, rail transit, construction, furniture, etc. One feature of CFRT is that it can not only be composited with other core materials through adhesives, but can also be laminated with thermoplastic core materials through heat melting.

Customized CFRT Face Sheet Solutions for Your Project

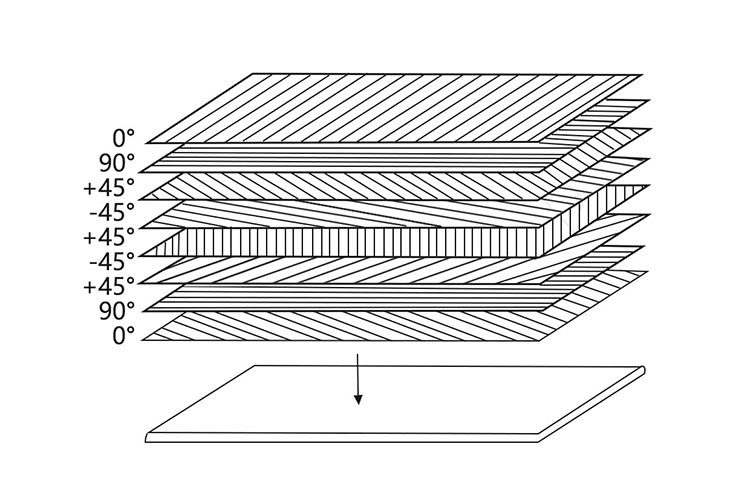

Laying Angles of UD Tape

- 0°: This layup consists of fibers aligned parallel to the loading direction. It has high stiffness and strength in the load direction.

- 0°/90°: This type of layup consists of two layers, one with fibers aligned in the 0° direction and the other with fibers aligned in the 90° direction. It provides good shear properties and is commonly used in applications where support of in-plane and out-of-plane loads is required.

- +45°/−45°: This type of layup consists of two layers, one with fibers aligned at an angle of ±45°. It provides balanced in-plane properties.

- Different resin systems and fiberglass contents are used according to needs.

- Provides composite testing.

- Provide performance test reports.

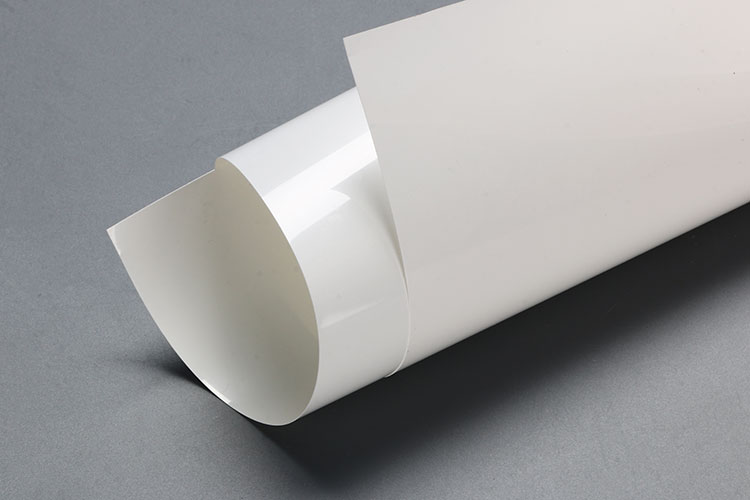

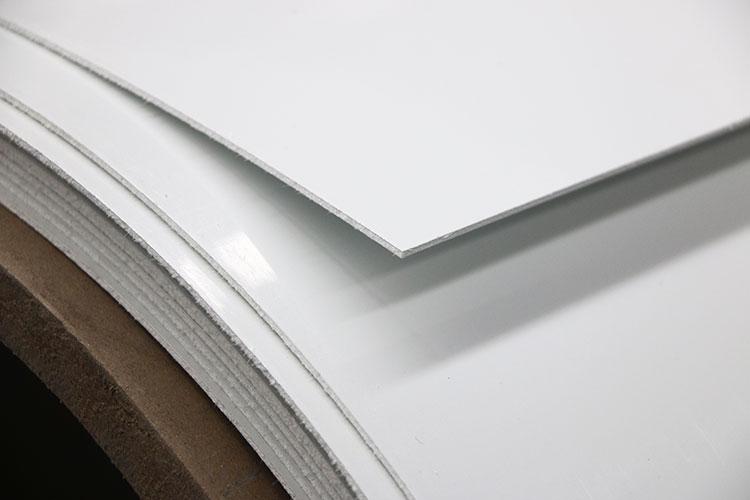

CFRT Sheet Samples

Our Advantage

International Advanced Production Equipment

We adopt independently developed automated thermoplastic production equipment standards to achieve high specifications, efficiency, high quality, high precision, safety, and environmental protection.

Premium Raw Materials

The plastic masterbatch and glass fiber yarn used in thermoplastic resin fully comply with the International Plastics Standardization Technical Committee and the pollutant emission standards of the glass fiber and products industry.It relies on electric heating to melt the resin and achieve fusion between UD tapes without producing any harmful gases.

High Specifications

The maximum thickness of thermoplastic sheets can reach 5mm, the maximum width can reach 2.8m, the length of each roll can reach 250m, and up to 10 layers of UD tapes can be thermally compounded. The thickness of thermoplastic honeycomb panels ranges from 6mm to 120mm.

High Efficiency

The production speed of thermoplastic composite panels reaches 3~8m/min, and 10,000m² CFRT sheets or thermoplastic composite panels can be produced every day. The annual production capacity can meet the production demand of 80,000 box trucks.

Safe and Reliable

The heating and cooling of thermoplastic sheets are in a closed space, which keeps production in a stable temperature environment and also protects the safety of operator