Fiberglass PU Foam Sandwich Panel

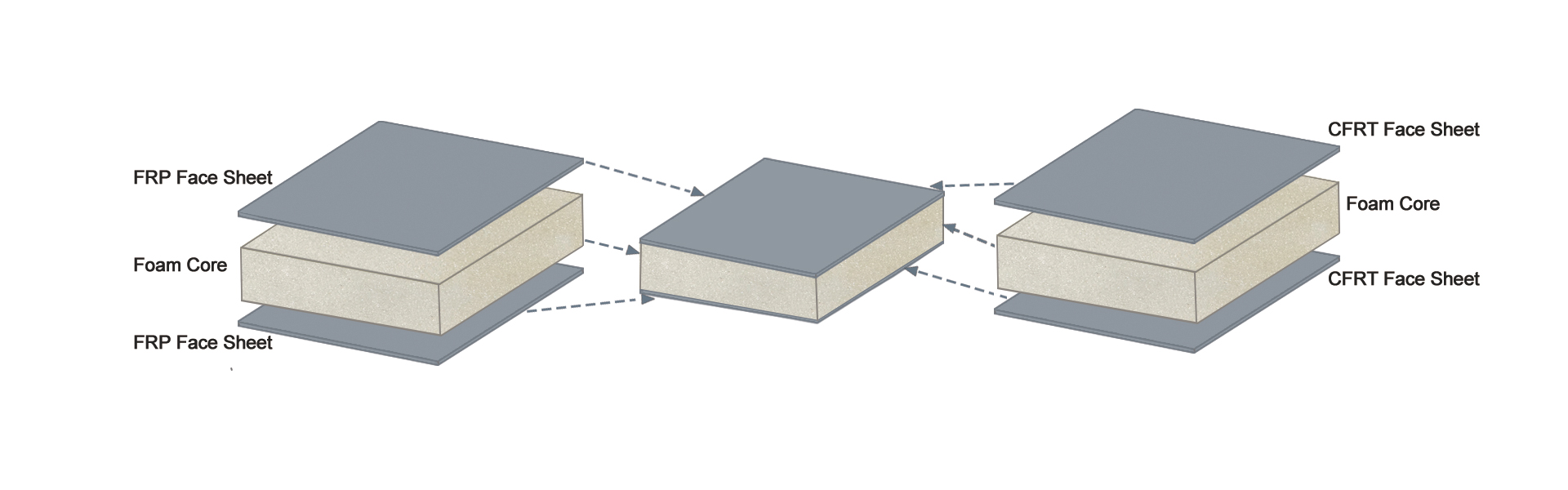

Our factory adopts the most advanced production technology and cleverly combines the advantages of FRP sheet and PU foam to create a lightweight and thermally insulating integrated composite panel — FRP skin PU Foam sandwich panel. This kind of board is both lightweight, high-strength and extremely thermally insulating. It is widely used in buildings, refrigerated truck bodies, cold rooms and other products with high thermal insulation requirements.

Basic Specifications

| Skin Material | Thermoset FRP | Thermoplastic CFRT |

| Core Material | PU Foam Core | |

| Skin Thickness | 0.7~5.0mm | 0.4~10mm |

| Length | ≤12m | |

| Width | ≤3.2m | |

| Surface Color | Natural, other colors can be customized | White,black,wood grain,natural |

| Surface Pattern | Glossy, matte, stone, weave, bubble, and imitation leather surface patterns | Glossy, matte |

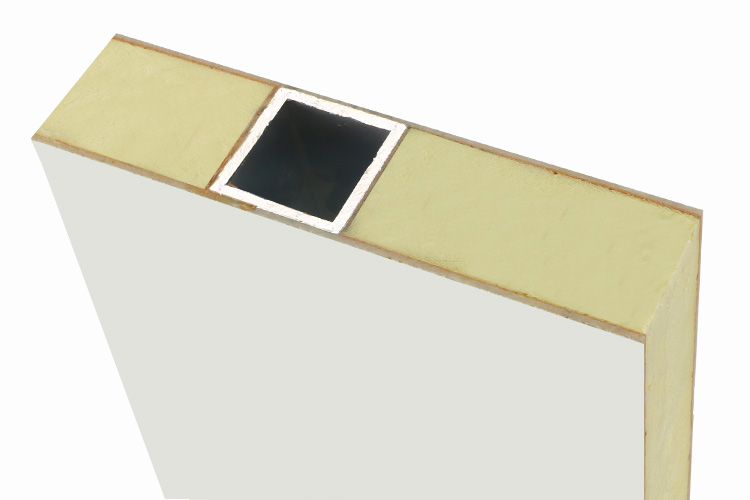

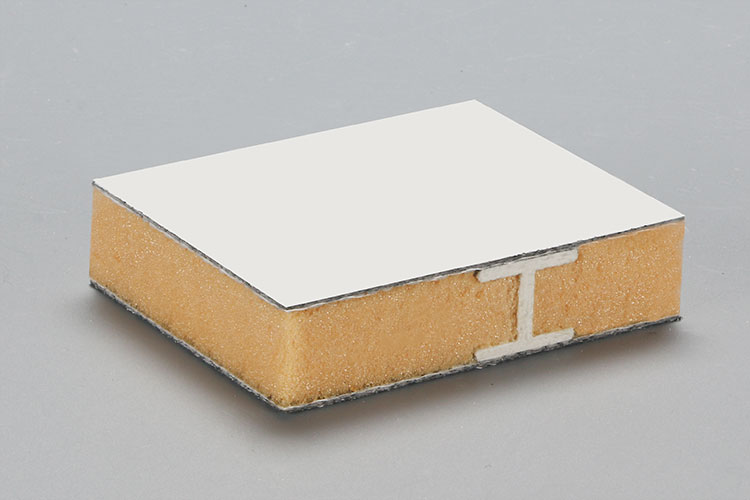

| Process Option | Embedded reinforcement materials; CNC machining services | |

| Total Thickness | 10~120mm (Customized) | |

FRP VS CFRT

| Skin Material | FRP | CFRT |

| Rigidity | Good | Very good |

| Impact Strength | Good | Very good |

| Scratch Resistant | Good | Very good |

| Surface Smoothness | Very good | Good |

| Corrosion Resistance | Very good | Good |

| Lightweight | Good | -35% |

| Tenacity | / | Good |

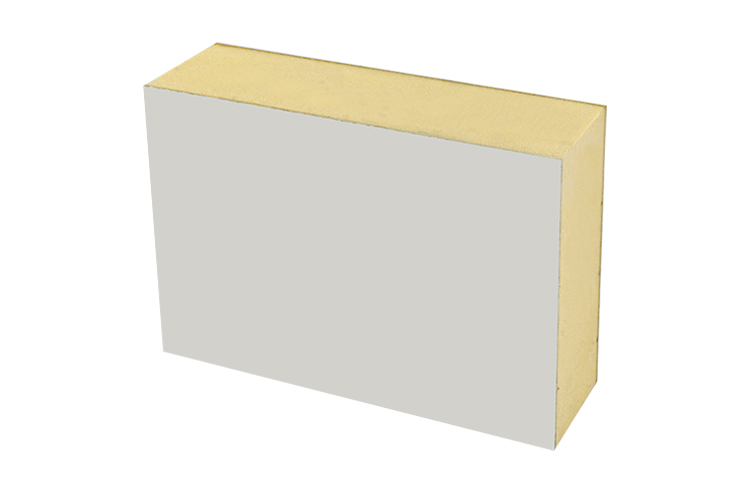

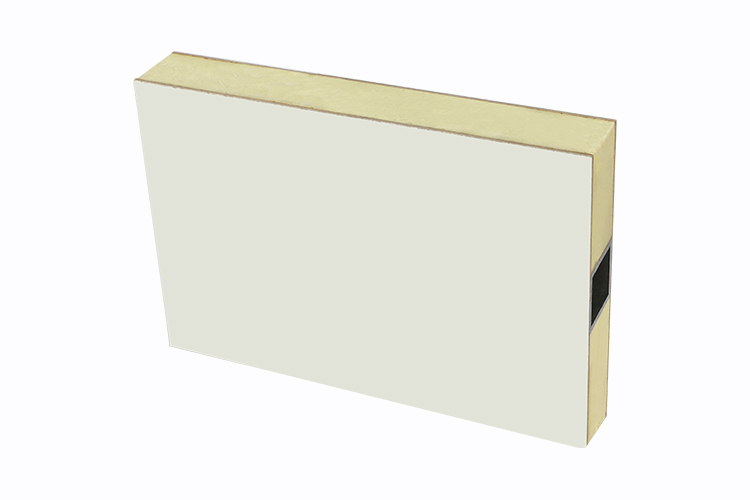

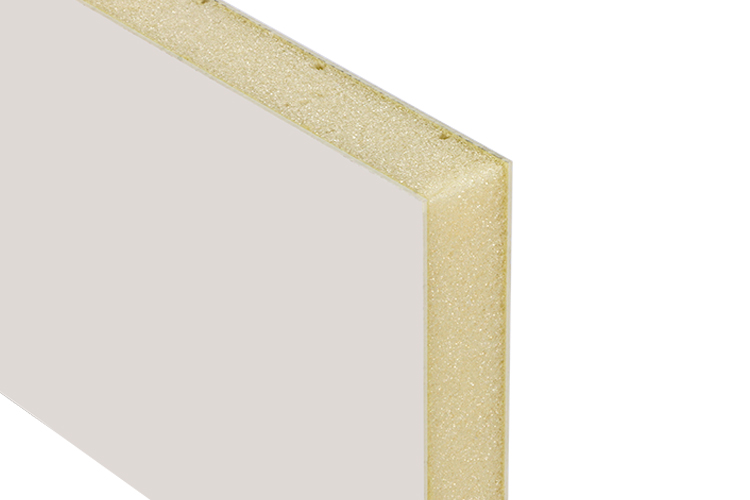

PU Foam Core Sandwich Panel Samples

Features & Benefits

- Excellent thermal insulation properties: Polyurethane foam has excellent thermal insulation properties, not only insulating heat but also providing good acoustic insulation. This makes FRP PU foam sandwich panels very useful in applications requiring insulation such as construction, refrigeration equipment and refrigerated vehicles.

- Lightweight but High Strength: Although very light, fiberglass PU foam sandwich panels have excellent strength and can withstand a certain amount of impact and pressure. This makes it ideal for projects that require structural support and protection.

- Excellent corrosion resistance: The outer layer of FRP has excellent corrosion resistance, making it less susceptible to erosion by water, acid, alkali and other chemicals. This makes it more durable for use in harsh environmental conditions.

- Easy to process: FRP PU foam sandwich panels are relatively easy to process and customize, and can be cut, shaped and connected according to specific needs. This reduces construction costs and time.

- Weather Resistance: The FRP outer layer can withstand UV rays and climate changes and is not prone to fading, aging or deformation, making it ideal for outdoor applications.

Technical Data

| Item | Standard | Unit | Data |

| External Color | / | / | White RAL9016 or 9003 |

| Thickness | / | mm | 80 |

| Areal Weight | / | kg/m2 | 7.85 |

| Regular Size | / | m | 6×2.4 |

| Foam Density | GB/T 6343-2009 | kg/m3 | 40 |

| Compression Strength | GB/T 8813 | KPa | 364 |

| Thermal Conductivity | / | W/M·K | 0.023 |

Applications

PU foam composite panels are mainly used in the insulation industry, such as refrigerated trucks, refrigerated trailers, mobile cold rooms, cold storage rooms, etc.