Aluminum facing foam sandwich panels are very common in our life. Their surface is aluminum skin and the core is foam board. Their advantages are waterproof, corrosion resistance, thermal insulation and good-looking. They are widely used in various insulation boxes and decorative wall panels.

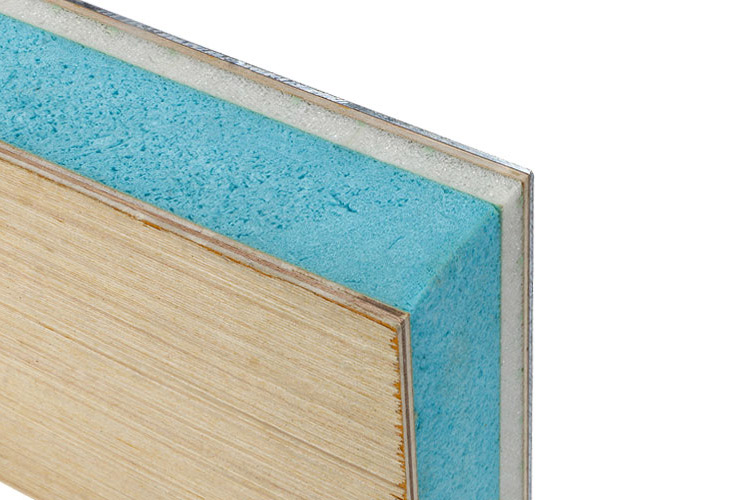

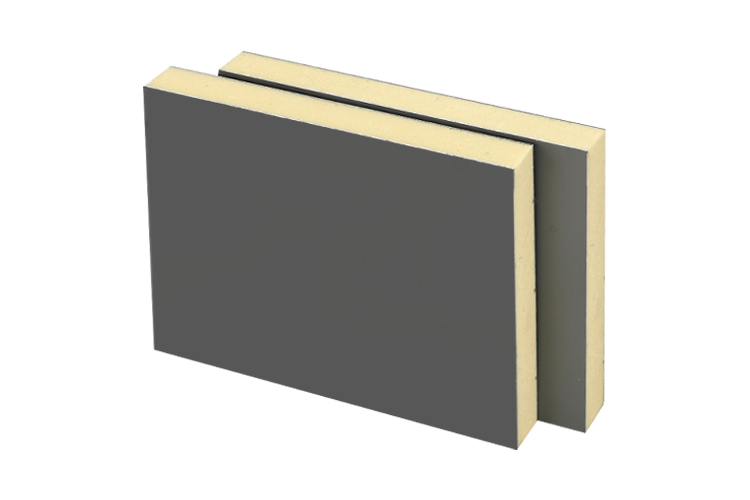

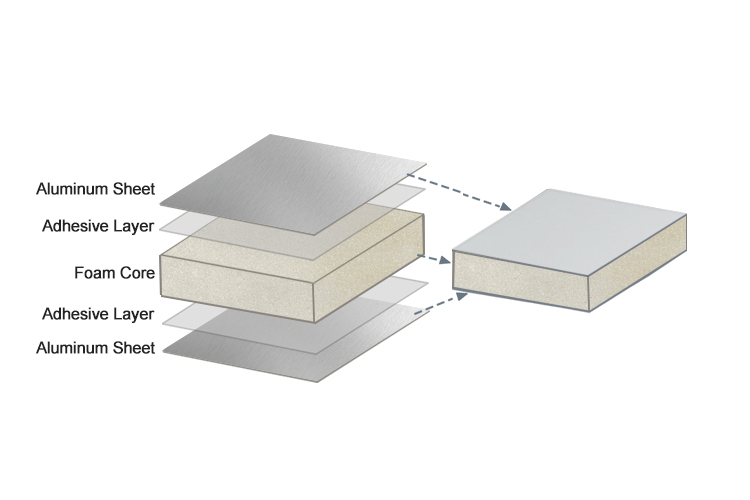

The Schematic of Structures

Aluminum Sandwich Panel

Aluminum Facing: It provides the appearance, durability and corrosion resistance of the sandwich panel. It can also have different surface treatments such as painting, anodizing or coating to enhance its aesthetics and protective properties.

Core: Common materials include XPS, PU, PET, PVC, etc. The foam core has lightweight, thermally insulating and shock-absorbing properties, which help to improve the insulating properties of the sandwich panel and reduce the overall weight.

Basic Specifications

| Aluminum sheet thickness | ≥0.1mm |

| Core Material | XPS/PET/PU/PU/PVC foam |

| Total Thickness | 10~120mm |

| Width | 800~2600mm |

| Length | ≤12m |

| Aluminum Grades | 1050, 1060, 1100, 1145, 1200, 1230, 1350, 2011, 2014, 2017, 2018, 2124, 2219, 2319, 3003, 3004, 3105, 5005, 5052, 5083, 5086, 6061, 6063 ,7075, 7050, 7049, 710 0, 8006, 8111, 8079, etc |

| Aluminum Surface Treatment | Sandblasting, polishing, glossy, matte, embossed, fluorocarbon coating, anodizing, etc |

| Aluminum Surface Color | RAL color, or customized pattern |

Samples

Surface Treatment