What is FRP Sheet?

Thermosetting glass fiber reinforced plastic (FRP/GRP) is a composite material composed of glass fiber and thermosetting resin. Surface coated with gel. As a new environmentally friendly material, it has stronger toughness than steel and aluminum products. The product will not crack, deform and prevent heat transfer at ultra-low or high temperatures. Therefore, FRP is widely used in many industries. Such as dry truck bodies, wall decorative covers, refrigerated truck bodies, RV/RV side panels, cold storage walls, etc.

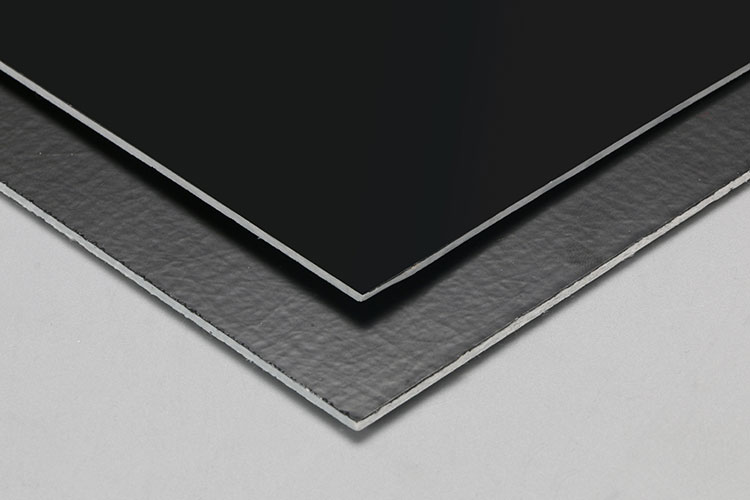

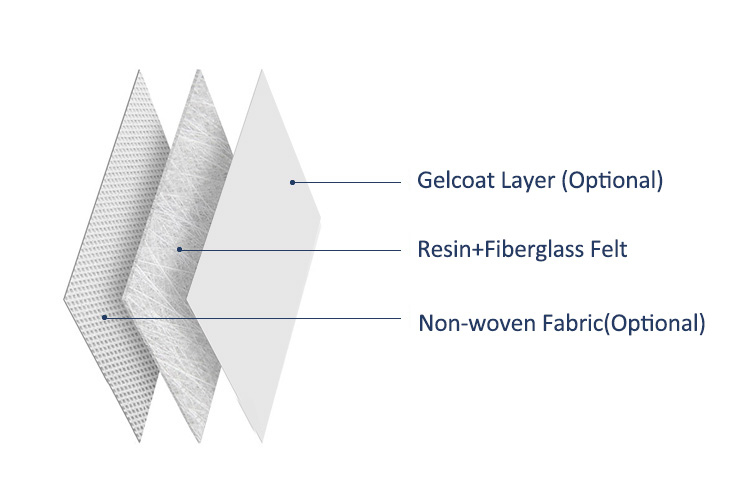

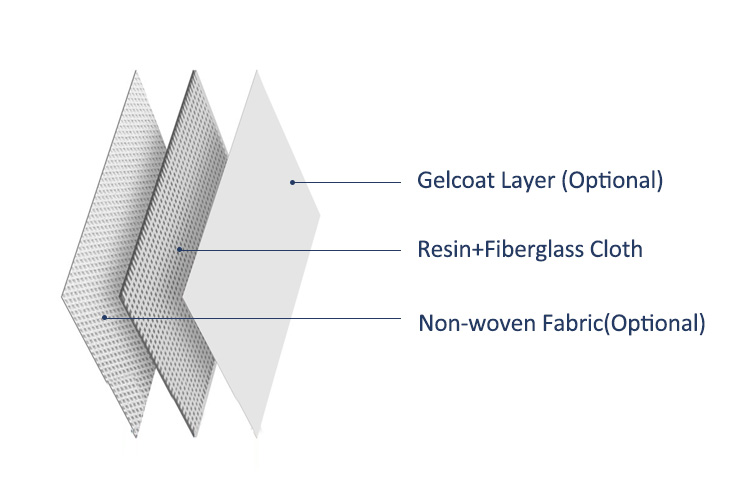

Fiberglass Sheet Structure

| Gelcoat Layer | Gelcoat is a protective surface coating that provides a smooth, shiny finish to FRP surfaces, making them more aesthetically pleasing |

| Fiberglass Reinforcement Layer | High-quality thermosetting resin + fiberglass felt or fiberglass cloth |

| Non-woven Fabric Layer | Non-woven fabric serves as a connecting layer, and FRP and other materials can be tightly bonded by spraying glue. |

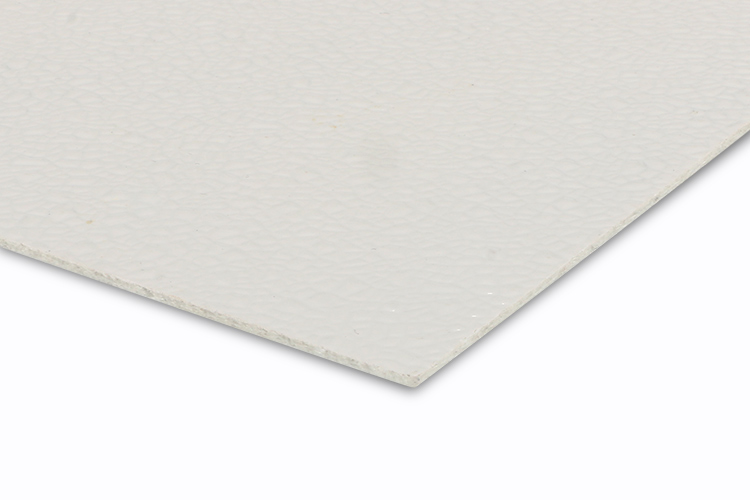

Felt-based FRP sheet

Resin+Fiberglass mat: Chopped fiber, continuous fiber mat, stitched mat, etc.

Advantages: Smooth surface, lower cost.

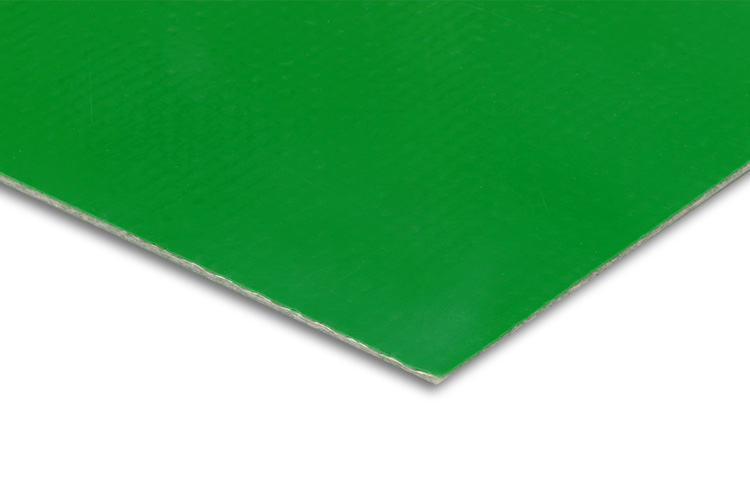

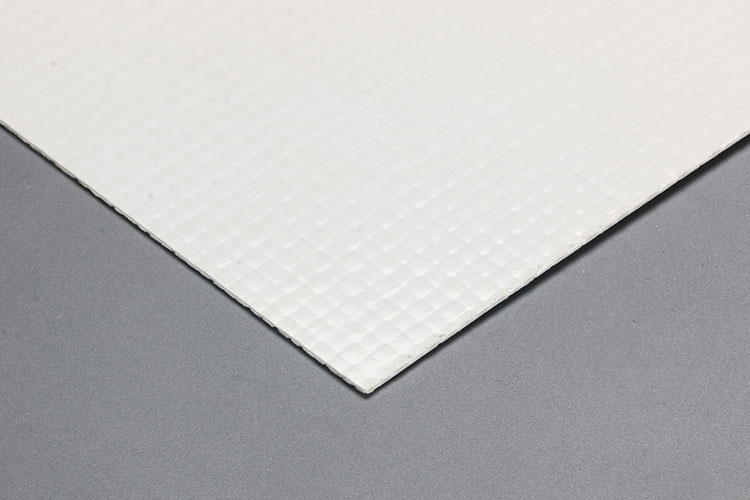

Cloth-based FRP Sheet

Resin+Fiberglass cloth: Mesh cloth, square cloth, plain cloth, axial cloth, etc.

Advantages: High strength and stable performance.

FRP/GRP Face Sheet Features

- High mechanical strength and good impact toughness

- Rough surface, easy to clean

- Corrosion-resistant and wear-resistant

- Resistant to yellowing and aging

- High temperature resistance

- No deformation, low thermal conductivity

- Excellent insulation properties

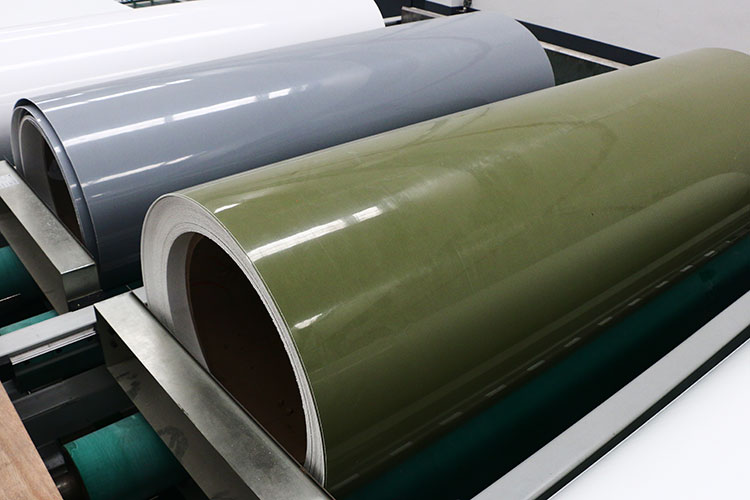

FRP FaceSheet Samples

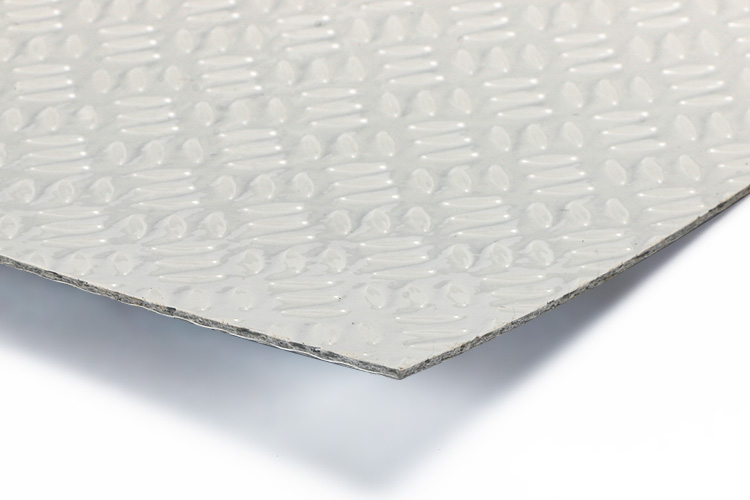

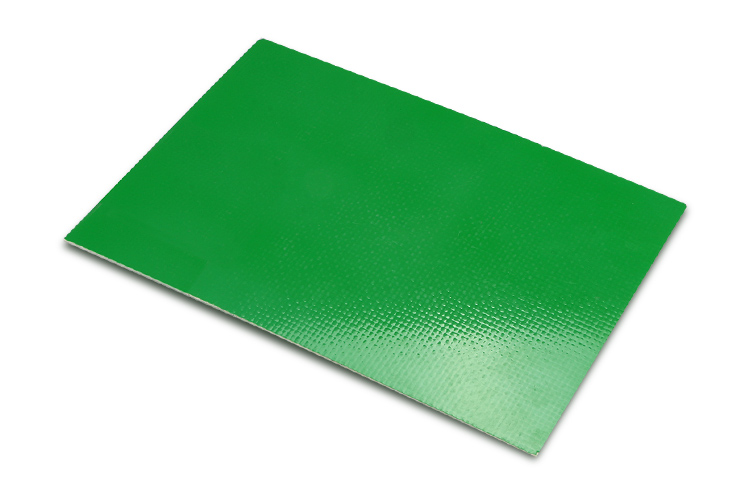

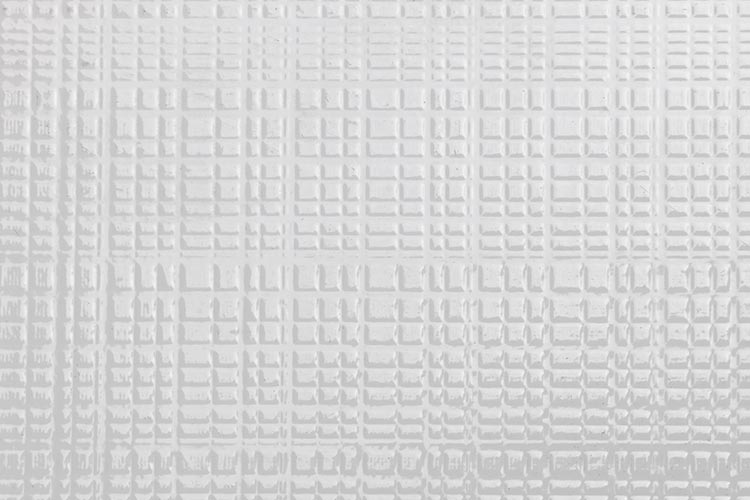

Fiberglass Panels with Various Surface Treatments Available

We offer gelcoated flat fiberglass panels in glossy, matte, stone grain, woven, bubble and faux leather surface patterns. If you need other patterns, please send us samples or detailed files.

.jpg)