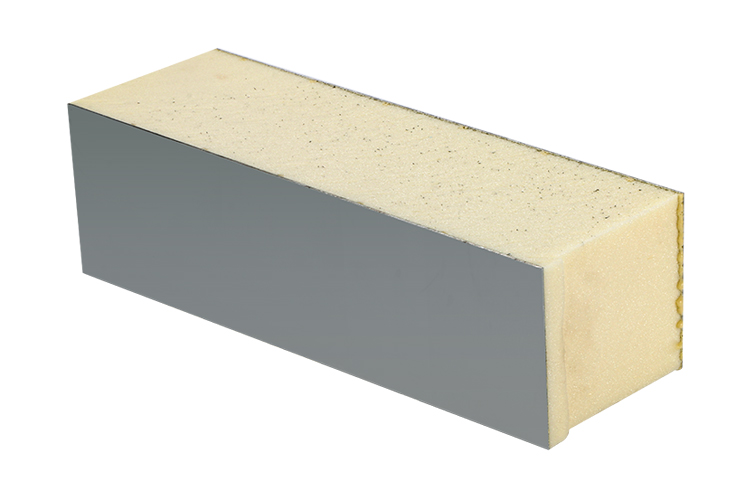

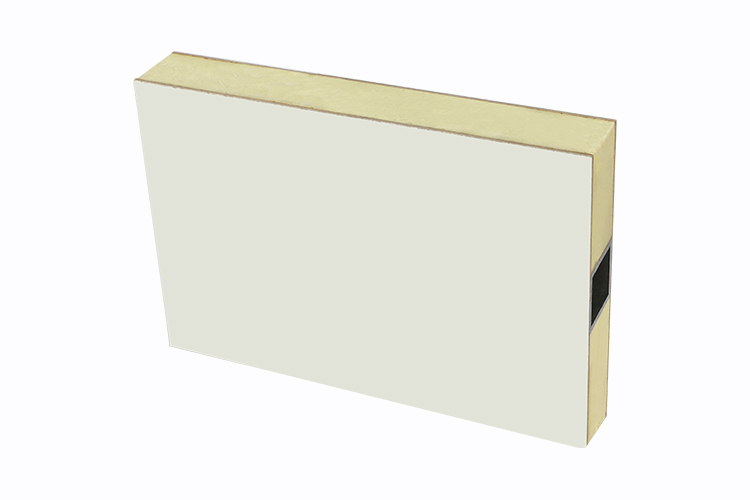

- Thickness: 70mm

- Skin Thickness: 2mm

- Core Material: Polyurethane foam

- Skin Material: CFRT sheet

- Surface Treatment: Matte, natural

- Area Weight: 14.3kg/m².

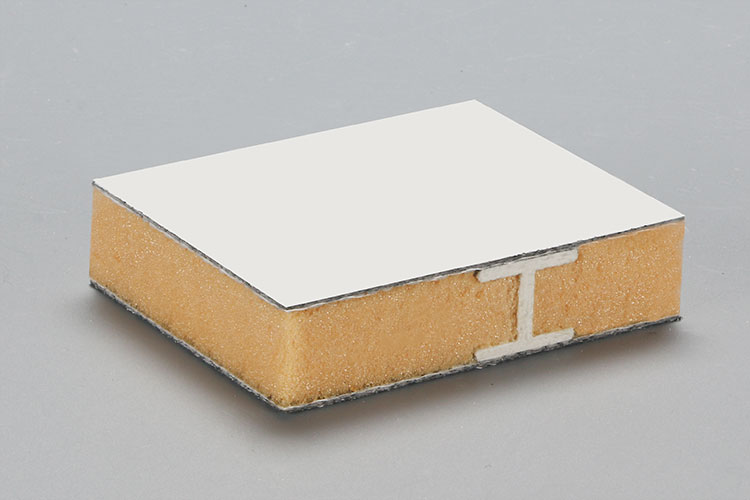

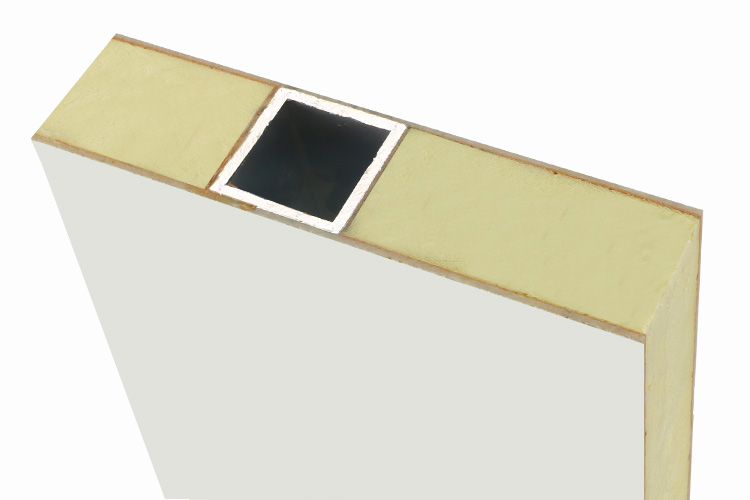

Surface layer——CFRT sheet

Different from thermoset FRP sheets, thermoplastic CFRT is thermally laminated from thermoplastic UD tapes and has higher structural strength.

- Highly rigid. The continuous fiberglass structure provides excellent toughness, and even large bending deformations will not cause damage to its structure.

- Good impact resistance. CFRT material can absorb a lot of energy when impacted, making the sandwich panel stronger and more durable.

- Corrosion resistant. CFRT can completely isolate moisture and most chemicals, which makes it less susceptible to corrosion and easier to clean.

Core layer

Using PU (polyurethane) foam core, its thermal conductivity is only 0.022~0.033W/(m*K), so it has excellent thermal insulation effect.

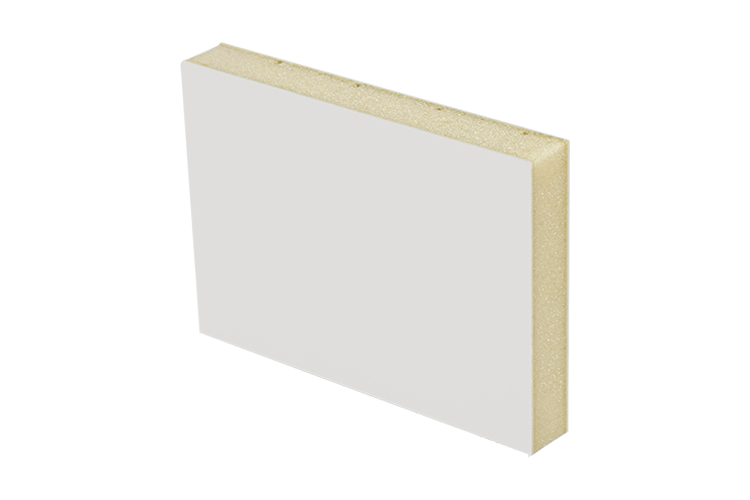

- Easy to process. PU foam is easy to cut, process and shape, and can be made into products of various shapes and sizes according to needs.

- Structurally stable. It has good dimensional stability and will not expand or shrink due to changes in temperature and other conditions.

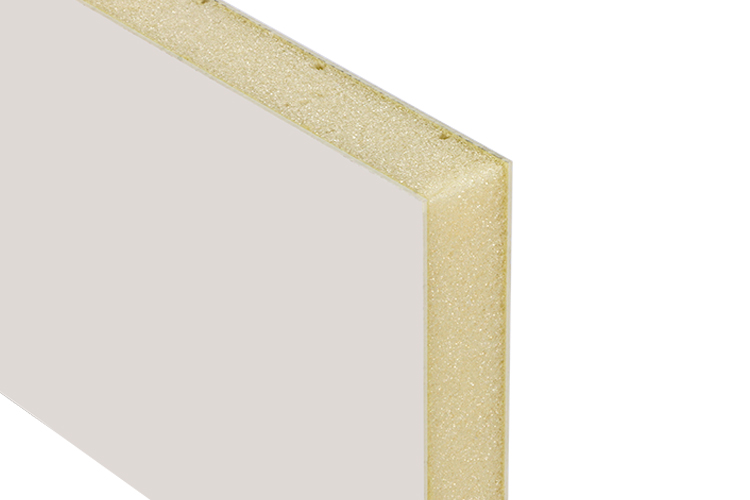

Application areas

Refrigerated trucks & Cold room

For refrigerated truck boxes and cold room, the most important thing is to ensure the quality and safety of the goods. Matte CFRT facing PU foam sandwich panel can provide good thermal insulation effect.