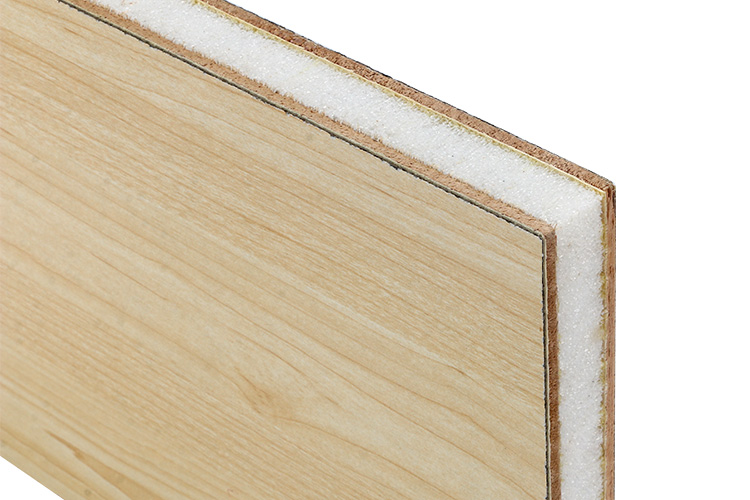

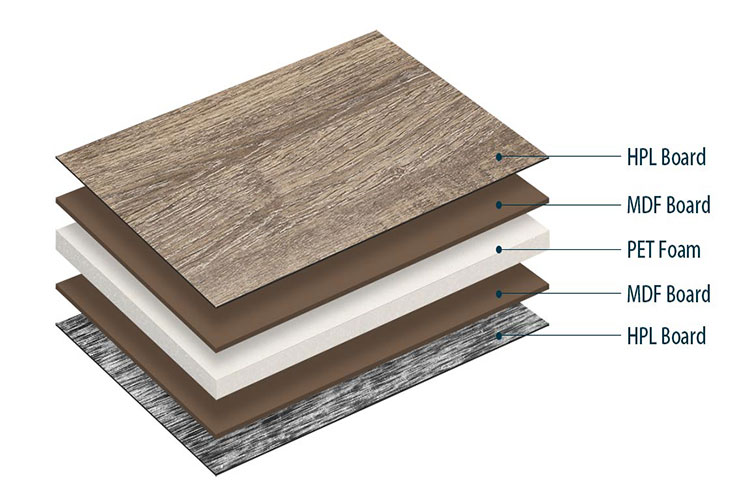

HPL sheet foam sandwich panel is a composite material with high strength, lightweight, durability, and aesthetics. The panel consists of three layers: the surface layer is HPL board (high-pressure laminate), the core material is PET foam, and the bottom layer is also HPL board. It is favored by furniture manufacturers and designers for its excellent properties such as being waterproof, fireproof, and wear-resistant.

Structure of HPL Sheet Foam Sandwich Panels

- HPL Board: The HPL (High-Pressure Laminate) board is a high-pressure laminate with many advantages such as water resistance, fire resistance, and antibacterial. Its surface color and texture are rich and colorful, making it widely used in fields such as construction and furniture manufacturing.

- MDF Board: MDF (Medium Density Fiberboard) is an engineered wood made by compressing wood fibers and adhesives. Due to its uniform density and smooth surface, it is widely used in furniture manufacturing, interior decoration, etc.

- PET Foam: Rigid PET foam has a higher density and hardness, making it better for situations requiring greater structural support.

Product Advantages

- High strength: The HPL hard surface combined with foam core provides excellent compression and impact resistance, making it suitable for frequently used load-bearing furniture or furniture parts.

- Lightweight design: PET foam core has extremely low weight, which can significantly reduce the overall weight of the panel. Easy to transport and install.

- Waterproof: The HPL layer has natural waterproof properties and can effectively block moisture penetration. It is suitable for furniture in humid environments, such as kitchen cabinets, bathroom cabinets, and outdoor furniture.

- Scratch resistant: HPL sheet is extremely durable and highly resistant to scratches and abrasions. Even after long periods of use, the panels retain their beautiful appearance.

- Easy to cut: HPL sheet foam sandwich panels are easy to cut, drill, and process, and can be customized according to specific design requirements.

- High nail-gripping power.

- Antibacterial properties: HPL surfaces are easy to clean and difficult to breed bacteria. They have good antibacterial properties and are suitable for environments with high hygiene requirements, such as furniture in public places such as hospitals and schools.

- Eco-friendly: The PET foam core does not contain any harmful substances during its production process and is recyclable.

Samples of HPL Sheet PET Foam Sandwich Panels

Applications

Furniture for interiors of RVs, mobile homes, hotels, hotels, villas, offices, etc.

HPL Sheet Pattern

We offer a variety of surface colors and patterns, and you can customize your own style.

For more information or to get a quote, please contact us and we look forward to providing you with high-quality HPL sheet foam sandwich panel solutions.