Home > Sandwich Panels > Thermoplastic Hoeycomb Panels

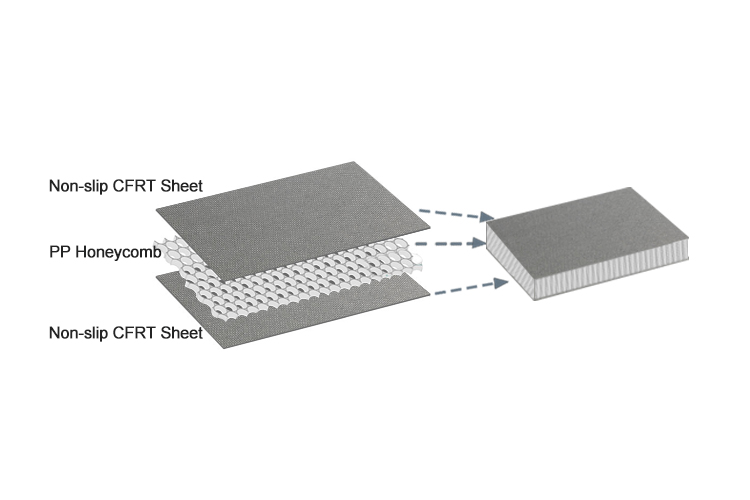

CFRT honeycomb sandwich panel is a sandwich structure panel whose skin is composed of CFRT (continuous fiberglass thermoplastic) sheets and the middle layer structure is a polypropylene honeycomb core. The core material and skin layer are pressed together by hot melting.

Features of Thermoplastic Honeycomb Panel

- Extremely lightweight

The material density of the honeycomb structure is low

- Extremely high strength

The continuous glass fiber reinforced material sheet has good impact resistance, rigidity and flexibility. It can withstand large physical stress impact

- Easy to process

Thermoplastic honeycomb panels are easy to cut, form, and process, and users can assemble them using screws, hollow rivets, adhesives, or hot melt welding.

- Weather resistance

Thermoplastic honeycomb panels offer good weather resistance, making them suitable for use in various climatic conditions.

- Corrosion resistance

Thermoplastic honeycomb composite panels resist corrosion from grease, salt water, and common chemicals.

- Reduce carbon footprint

Due to the lightweight of thermoplastic honeycomb panels, when used in transportation vehicles such as cars, airplanes, ships, etc., it can effectively reduce fuel consumption and thus reduce carbon emissions.

Specifications

- Skin material: CFRT (Continuous Fiberglass Thermoplastic) sheet. (Thickness: 0.4~2.5mm)

- Core material: Polypropylene Honeycomb. (Cell diameter: 80/120mm)

- Length: within 12m.

- Width: within 3.2m.

- Thickness: 10~120mm.

- Surface Treatment: Non-slip, anti-UV, fireproof, film, coloring

- Color: Natural

- Flatness: ±4mm/m

- Honeycomb Diameter: 6~16mm

Compressive Strength

| Thickness (mm) | 15 | 20 | 25 | 30 | 45 |

| Core material density (Kg/m³) | 100 | 80 | 80 | 80 | 80 |

| Compressive strength (MPa) | 2.9 | 1.8 | 1.89 | 1.82 | 1.75 |

| Compression modulus (MPa) | 93.6 | 38.3 | 39.5 | 39.4 | 37.8 |

| Maximum load (N) | 163124 | 10121 | 104.8 | 10239 | 98439 |

Bending Strength

| Thickness (mm) | 15 | 20 | 25 | 30 | 45 |

| Damage load (N) | 1417 | 1722 | 2005 | 2568 | 3051 |

| Specific stiffness (N·m/kg) | 1.13 | 1.8 | 2.6 | 3.8 | 4.5 |

| Density (Kg/m³) | 260 | 213 | 182 | 170 | 140 |

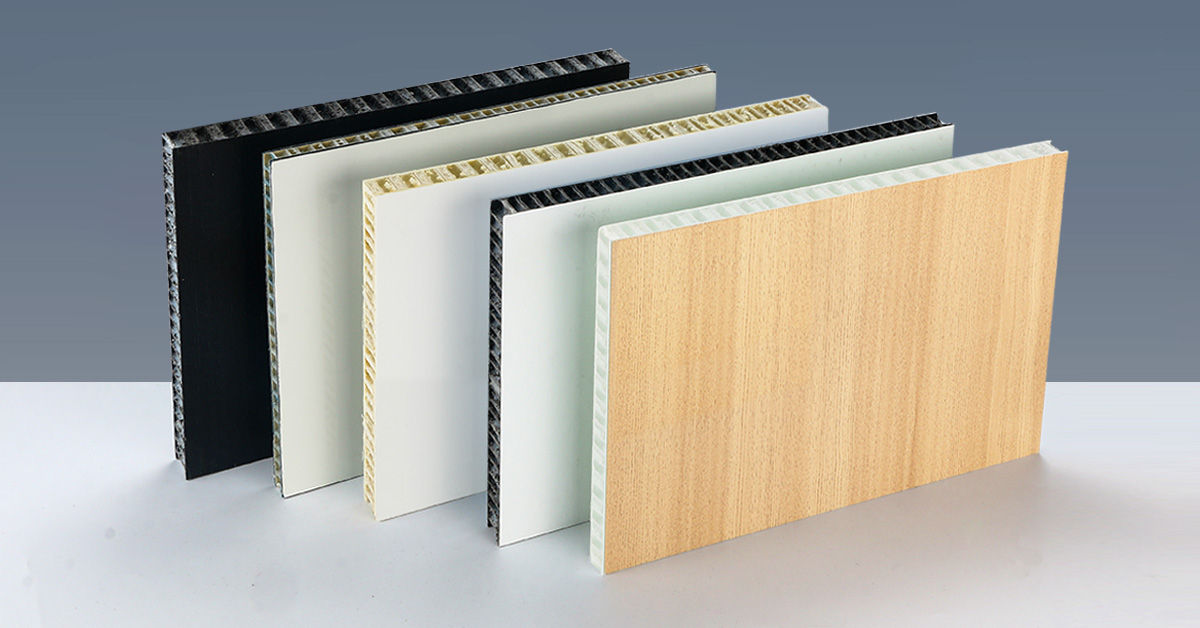

Thermoplastic Honeycomb Panel Samples

-

12mm Antiskid Black New FRP Facing PP Honeycomb Panel

12mm Antiskid Black New FRP Facing PP Honeycomb Panel -

Wood Grain Skin Honeycomb Sandwich Panel

Wood Grain Skin Honeycomb Sandwich Panel -

Anti-slip Rubber Pad Honeycomb Panel for Cowshed

Anti-slip Rubber Pad Honeycomb Panel for Cowshed -

Carbon Black Fiberglass Honeycomb Panel

Carbon Black Fiberglass Honeycomb Panel -

Black Anti-skid Honeycomb Panel for Trailer Floor

Black Anti-skid Honeycomb Panel for Trailer Floor -

New FRP Anti-skid PP Honeycomb Panel

New FRP Anti-skid PP Honeycomb Panel -

Wood Grain Painted PP Honeycomb Panel

Wood Grain Painted PP Honeycomb Panel -

PVC Floor Leather Honeycomb Panel

PVC Floor Leather Honeycomb Panel

Surface Treatment

We provide a variety of surface treatments for Thermoplastic Honeycomb Panels, such as UV resistance, anti-skid, embossing, adding flame retardants, and pasting decorative films, etc.