As the global shipping industry increasingly attaches importance to efficiency and environmental protection, PVC foam sandwich materials have become an important choice in ship design due to their significant advantages such as lightweight and corrosion resistance.

As a high-performance sandwich material, PVC foam core can effectively reduce the weight of the hull and maintain stable performance for a long time in harsh environments, helping the shipbuilding industry to transform towards green.

Explore the Benefits of PVC Foam in Ship Hull

Marine PVC foam core is a lightweight, high-strength, water-resistant sandwich material.

Benefits

- Lightweight: PVC foam reduces hull weight by 20 to 40%

- Corrosion Resistance: It can effectively resist seawater, sal spray and other corrosive factors

- Structural Strength: Combining PVC foam with metal panels or composite skins can increase the strength and rigidity of a vessel.

- Easy to Process: Cut and formed to suit hull shape to suit a variety of vessel designs

Ship Hull Foam Core Processing

- Flat foam

Foam boards are used directly after slicing without requiring additional processing. For curved surface applications, flat thermoforming technology shapes the foam as needed.

- Perforated foam

Evenly distributed 2mm diameter holes are made in the foam, with the hole size adjustable based on the foam’s thickness and density. These holes facilitate resin penetration and air exhaust.

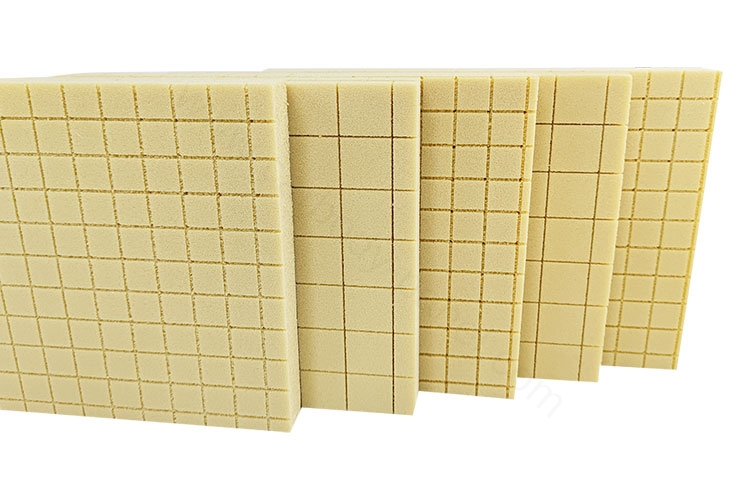

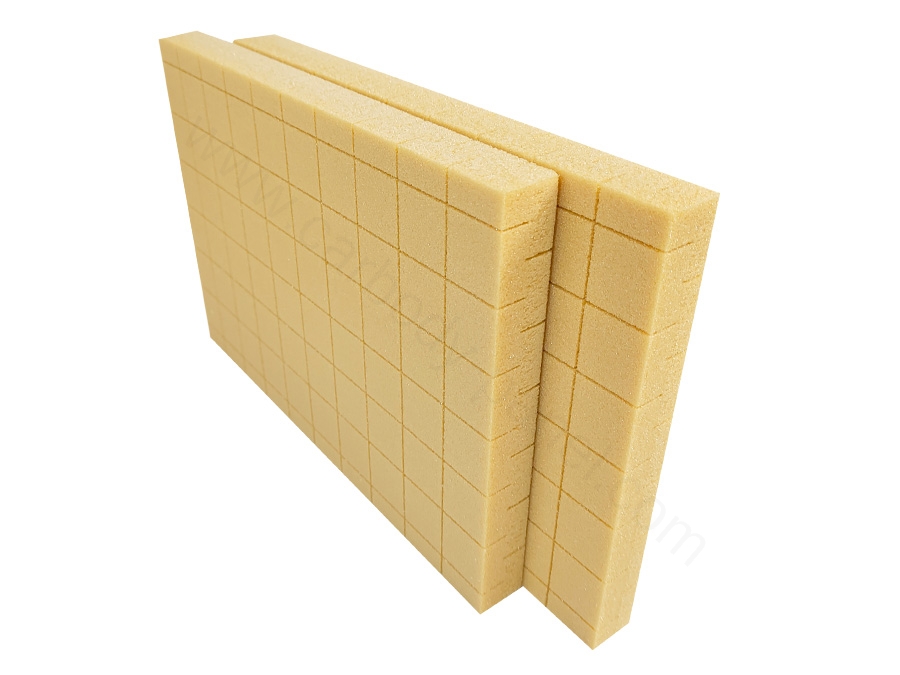

- Groove foam

Grooves are engraved on the foam surface to create resin flow paths, which can be one-sided or double-sided, and one-way or two-way. The groove design optimizes the resin infusion process and effectively exhausts the air.

- Groove + perforated foam

Add 2mm diameter holes in the groove with a spacing of about 20mm. This design combines the advantages of perforation and groove to improve the efficiency of resin penetration.

- Hyperboloid foam

Cut the foam to about 55-60% of its thickness, with staggered cut lines on both sides, designed for curved surfaces. This method reduces resin absorption compared to full contour cutting.

- Corrugated foam

The foam has one side cut into granules while the other side features fiberglass mesh cloth. making it suitable for complex curved surfaces and enhancing structural strength and adaptability.

Parameters

| ITEM | P60 | P80 | P100 | P130 | P200 |

| Density(kg/m³) | 60 | 80 | 100 | 130 | 200 |

| Tensi le Strength(Mpa) | 1.8 | 2.5 | 3.5 | 4.8 | 7.1 |

| Tensi 1e Modulus (Mpa) | 75 | 95 | 130 | 175 | 250 |

| Compressive Strength(Mpa) | 0.9 | 1.4 | 2 | 3 | 4.8 |

| Compressive Modulus (Mpa) | 72 | 90 | 135 | 170 | 240 |

| Shear Strength(Mpa) | 0.76 | 1.15 | 1.6 | 2.2 | 3.5 |

If you have any questions or custom requirements for PVC foam for boat hull material, please contact us. Our team will provide you with professional advice and services to help your boat building project succeed.

Email: info@carbody-panel.com

Contact Us