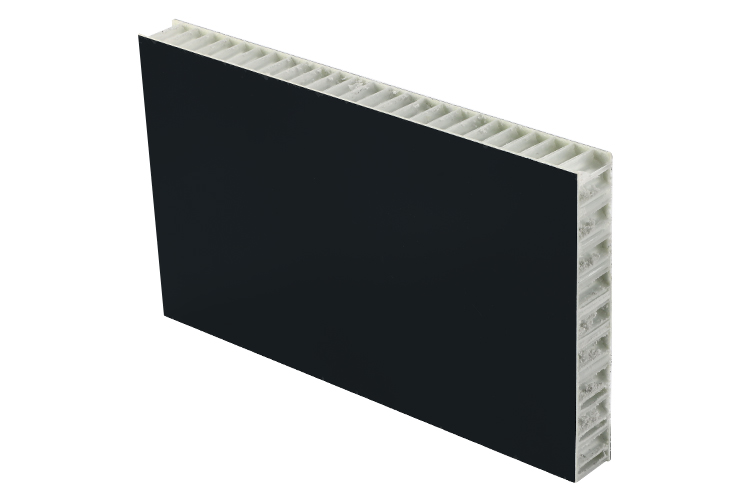

Product Parameters

- Total Thickness: 26.0mm. (Customized)

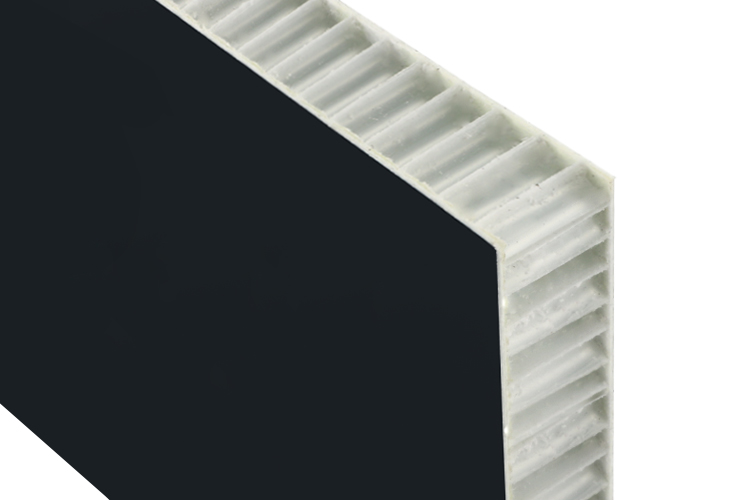

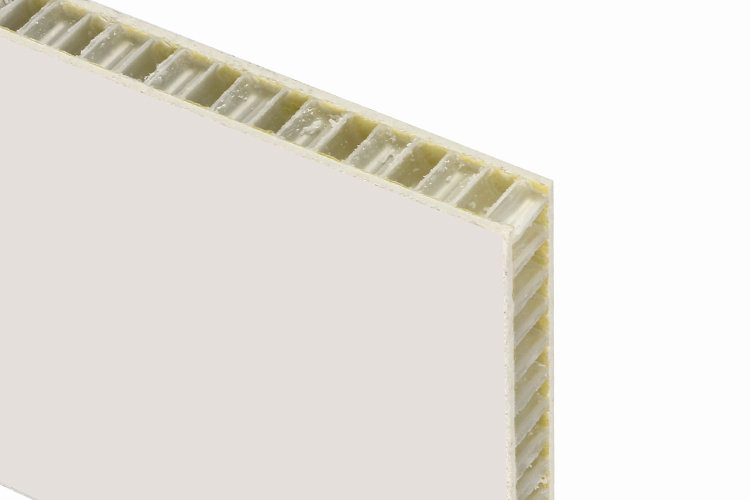

- Upper Skin: 2.0mm FRP sheet. (Customized)

- Core Material: 80kg/m³ polypropylene honeycomb.

- Lower Skin: 2.0mm GRP sheet. (Customized)

- Area Weight: 6.5kg/m².

- Applications: Box truck bodies, partitions, tabletop panels, cabinet panels, ceilings, etc.

Description

Features of Matte FRP Sheet Honeycomb Sandwich Panel

- Lightweight

PP honeycomb core is relatively lightweight and suitable for applications that require light weight but sufficient strength.

- High strength

The FRP (fiberglass reinforced plastic) skin gives the sandwich panel good strength and stiffness, allowing it to withstand certain loads and cope with various environmental conditions.

- Corrosion resistance

FRP material has excellent corrosion resistance and is suitable for various harsh environments, such as moisture, chemical contact, etc.

- Thermal insulation performance

PP honeycomb core has good thermal insulation performance and can reduce heat conduction to a certain extent.

- Easy to process

Both FRP and PP materials are relatively easy to process, and processing techniques such as cutting and shaping can be carried out according to specific needs.

Applications

- Light vehicle interior parts

Siding, flooring, etc. for trucks and buses.

- Ship internal components

Cabin walls, cabin partitions, etc.

- Construction

Wall panels, roof panels, etc., with good strength and weather resistance.

- Aerospace

Aircraft interior decoration parts, bulkheads, etc. are required to be lightweight but have a certain degree of strength and durability.