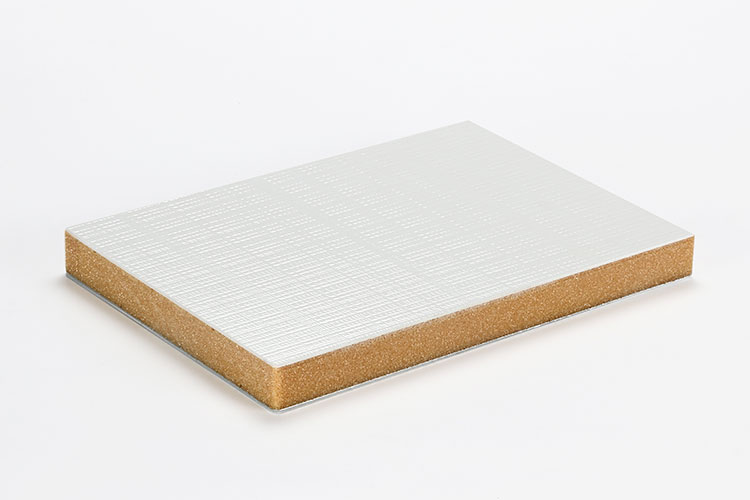

Product Structure

- Surface Material: Anti-slip Aluminum Plate

- Core Material: PVC Foam Core

- Back Material: CFRT Sheet

Basic Specifications

- Length: Max 12m

- Width: Max 3.2m

- CFRT Sheet Thickness: 0.7mm~5mm

- Aluminum Plate Thickness: 1.0mm~5mm

- PVC Core Thickness: 3mm~60mm

- Core Density: 50~100kg/m3

Description

What Is Anti-slip Aluminum Skin PVC Foam Sandwich Panel?

Anti-slip aluminum panels are also called patterned aluminum panels or diamond panels. Their biggest feature is the raised diamond or linear texture on the surface. They are safe, comfortable, durable, and, most importantly, wear-resistant and non-slip.

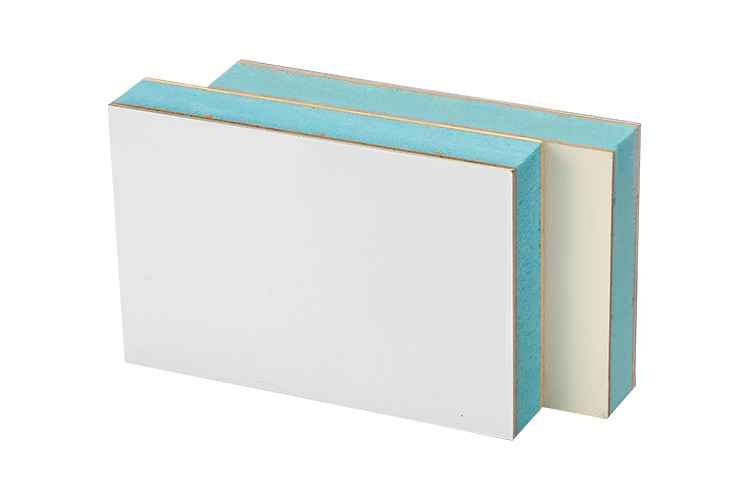

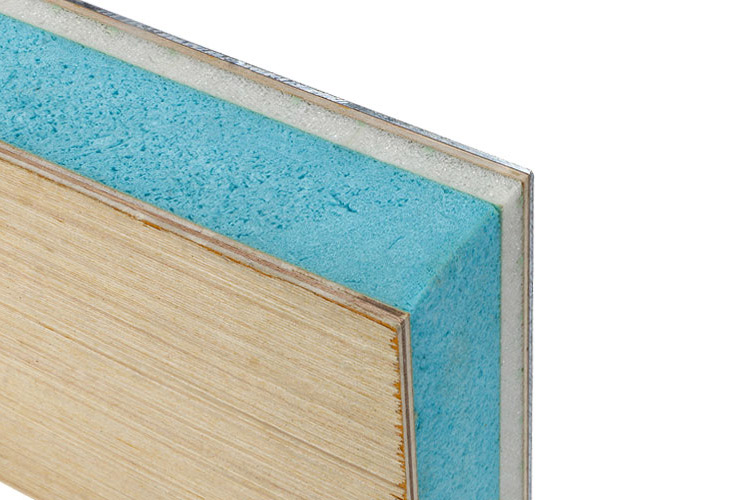

Panel structure

- Upper surface layer

Diamond pattern aluminum sheet. This design greatly enhances the friction and anti-slip performance of the entire panel.

- Middle layer

PVC (polyvinyl chloride) foam core for lightweight insulation. Its cell structure helps reduce sound transmission and can be used as a soundproof floor to reduce noise.

- Lower surface

Non-woven + GRP sheet structure. As the back of the floor, can provide sufficient support strength.

Application areas

- Transportation

Anti-slip aluminum skin PVC foam sandwich panels are widely used in buses, trains, ships, and other transportation vehicles. The raised texture on their surface greatly reduces the possibility of people slipping.

- Construction site

It can be used as the temporary floor at the construction site to ensure the personal safety of workers during construction.

- Ports and terminals

The ground in such places is always wet all year round, and the anti-slip aluminum skin PVC foam sandwich panel can provide a non-slip surface and a comfortable stepping effect.

- Agricultural vehicles

This type of panel can be used on vehicles that transport farm livestock and crops. Provide better anti-slip and shock absorption effect.