Specifications

- Standard: 1220*2440*3mm 1220*2440*4mm

- Non-standard size: Plate thickness: 2mm, 5mm, 6mm

- Width: 1000mm, 1250mm, 1500mm, 1550mm, 2000mm

- Core layer: Class B2, FR, HFR, A2

- Surface treatment: Anodic oxidation, brushed, aluminium foil decoration, mirror, PE coating, printing, PVDF coating, nano.

Description

Aluminum-plastic composite panel (also known as aluminum composite panel) is a new type of decorative material. It is made of chemically treated coated aluminum plate as the surface material, polyethylene plastic or high mineral content as the core material, and processed and compounded.

Aluminum-plastic composite panels have many excellent material properties, such as economy, color diversity, convenient construction, easy processing, and good fire resistance. Therefore, aluminum-plastic composite panels are widely used in all aspects of building decoration and have become one of the representative materials of metal curtain walls.

Aluminum Composite Panel Properties

Impact resistance

Aluminium composite panel consists of two pieces of aluminium and core materials such as PE, FR, etc. It has excellent structural strength, strong impact resistance, high toughness, bending and folding without damage to the finish, and will not be broken due to wind and sand in areas where sandy climate is more common.

Super weather resistance

it is high temperature resistant and not easy to be corroded by water and most of the chemicals, which is very suitable for outdoor environments; no matter in the hot sunshine or cold wind and snow, it will not lose its beautiful appearance, and it can be up to 20 years without fading.

Easy maintenance

Aluminium composite panels are self-cleaning in terms of pollution resistance. After a few years of use, if you need to maintain and clean up, you only need to use neutral cleaning agent to clean it, and after cleaning, the plate will be restored as new.

Light material

Aluminium composite panel weighs between 3.5-5.6kg per square metre, which can reduce the harm of earthquake and is easy to carry, and its superior simplicity and speedy construction can be matched with the designers to make a variety of shapes, which reduces the construction cost.

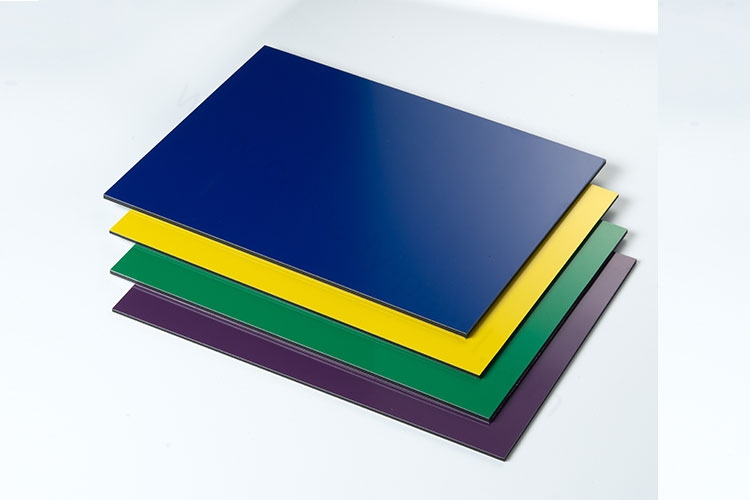

Diversified colors

Our aluminium composite panels have a variety of colours to choose from, smooth and beautiful and uniform adhesion between the coating and the aluminium composite panels.

Easy to process

Aluminium composite panels can be processed with ordinary woodworking or metalworking tools without the use of special tools. It can be easily cut, grooved, punched, drilled, bent and rolled. Aluminium composite panels are therefore virtually unlimited in shape and can be machined into a variety of complex forms.

Excellent fire resistance

These panels have a class B1 fire rating. It is difficult to catch fire in open flame or under high temperature in the air, the fire is not easy to spread, and the burning stops immediately when the fire source is removed. Therefore, Aluminium composite panel can well prevent the building from large-scale fire, causing excessive damage.

Ultra-high peeling strength

Our company adopts the most advanced technology and raw materials to improve the peeling strength, the most critical technical index of aluminium composite panels, to an excellent state, exceeding the national standard by more than 50%, ranking the leading level. At the same time, the flatness of the aluminium composite panel is improved accordingly.

Applications of Aluminum Composite Panel

- Curtain walls, interior and exterior walls, foyers, restaurants, shops, conference rooms.

- Counters, signage, billboards, interior partitions.

- Furniture facings.

- Interior and exterior walls of vehicles.

- Exterior wall hangings of high-rise buildings, interior partitions, interior decoration.

- Building level, advertising signs, etc.

Project Solution Capabilities

Graphic design, 3D modelling, total project solutions, cross-category integration.

If you need more solutions for aluminum-plastic composite panels, please contact us.