Home > Markets > Refrigerated Truck Body

Carbody focuses on researching ways to improve the lightweight design and strength of refrigerated truck bodies. To reduce weight and increase the efficiency of refrigerated trucks, we have developed a range of innovative composite materials for truck bodies.

These new materials reduce the truck body’s weight, increase impact resistance, and extend the service life of the truck box.

Lightweight & High-strength Materials

First of all, our body skin material uses antibacterial, anti-UV, and scratch-resistant Fiberglass sheets instead of metal skins (such as galvanized steel, stainless steel, aluminum, etc.). We have also developed a new type of FRP – CFRT (Continuous Fiber Reinforced Thermoplastic) as the skin material, which provides higher compressive and impact resistance.

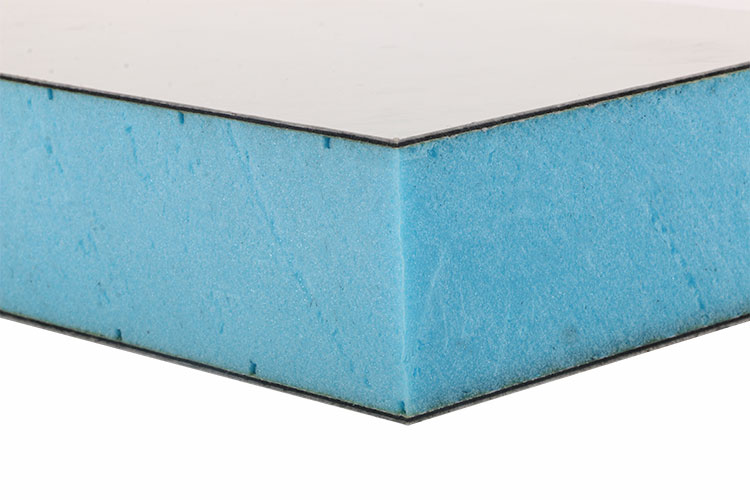

Secondly, we use non-water-absorbent rigid foam (PU, XPS). These foam core materials have stable performance, do not rot or deform, and will not produce any performance changes during the service life of the refrigerated truck.

Thirdly, we use lightweight and high-viscosity environmentally friendly adhesives, and the panels will not delaminate (separate the core material and skin material) in the temperature range of -40~80°. It has no peculiar smell and does not produce any harmful gases.

Fourth, we design a series of lightweight and high-strength components. Our designers will design various profiles, sheet metal, and other components according to customer needs.

We Design a Variety of Refrigerated Truck Body Solutions

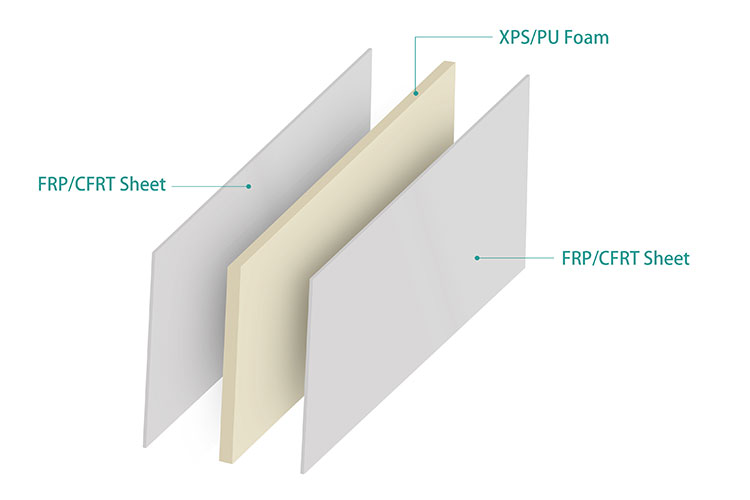

Ordinary Foam Sandwich Panel

It is a typical sandwich structure, especially suitable for small or mini-type refrigerated trucks, which is an economical and suitable choice.

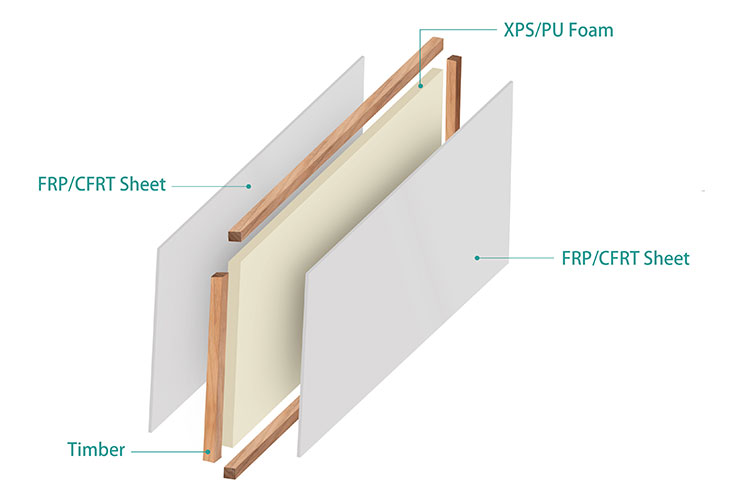

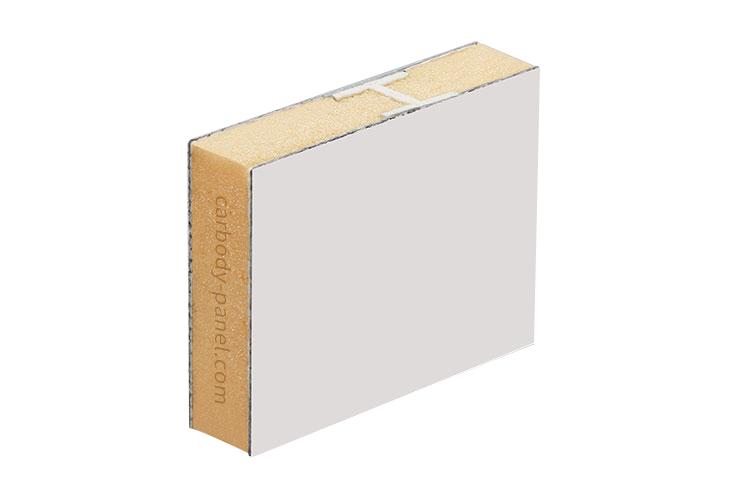

Waterproof plywood Timber Frame Sandwich Panel

Waterproof plywood is used as the frame structure of the sandwich panel, which not only maintains the lightness of the wood but also overcomes the problem of it being easily rotted when exposed to water, and provides sufficient strength support between the boards.

In addition, the excellent nail-holding strength of wood also facilitates the installation of other accessories.

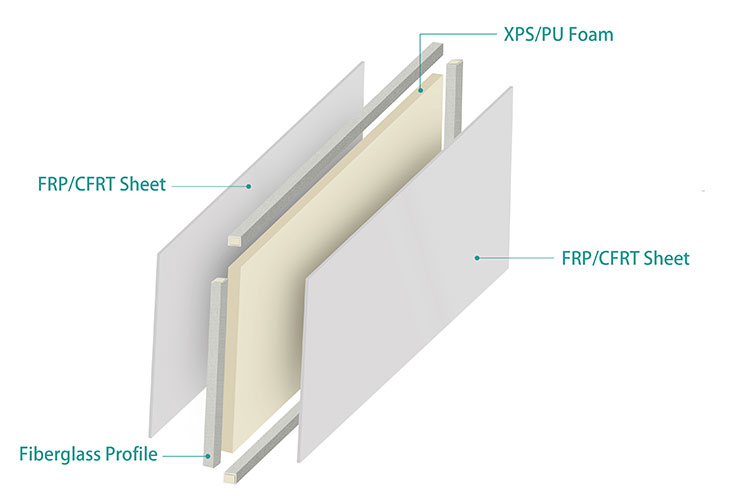

Continuous pultruded fiberglass frame sandwich panels

High-strength continuous fiberglass reinforced polymer material as frame structure

Benefits of FRP components:

Lightweight, high strength, high-temperature resistance, and not easy to deform.

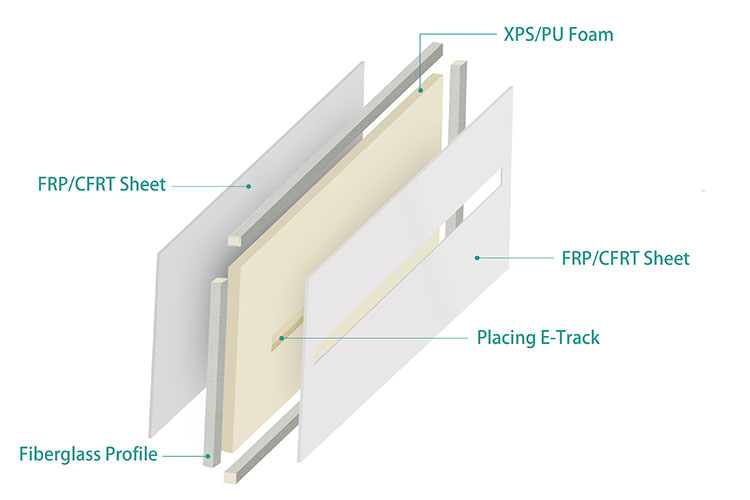

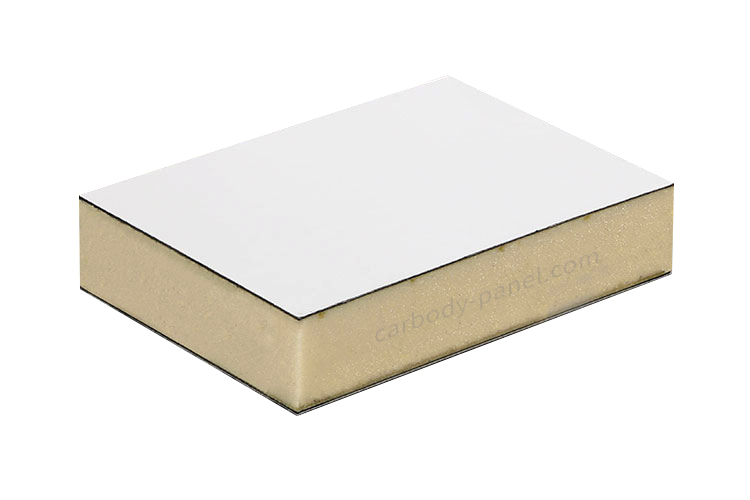

Recessed Cargo-Track Sandwich Panel

It is developed based on the continuous pultruded fiberglass frame structure sandwich panel, with a Cargo-track installed inside the sandwich panel.

This advanced design method not only makes the surface of the side panels of the refrigerated truck smooth, reducing the risk of damage to the cargo and the E-track system itself but also increases the space inside the box.

Advantages of Refrigerated Truck Body Design

- Accessories

Door locks, hinges, new high-strength molds, food-grade stainless steel, better appearance, better details.

- Adaptable to different widths of chassis

The patented design, which can adjust the width of the underframe beam, can be better adapted to different chassis.

Samples of Refrigerated Truck Body Materials

-

High Gloss PET Film PU New Fiberglass Sandwich Panel

High Gloss PET Film PU New Fiberglass Sandwich Panel -

GRP Laminated PU Sandwich Panel for Refrigerated Body

GRP Laminated PU Sandwich Panel for Refrigerated Body -

Embossed FRP Facing Polyurethane Foam Composite Panels

Embossed FRP Facing Polyurethane Foam Composite Panels -

GRP Polyurethane Foam Sandwich Panels for Refrigerated Trucks

GRP Polyurethane Foam Sandwich Panels for Refrigerated Trucks -

Polyurethane Foam FRP Sandwich Panels for Refrigerated Trucks

Polyurethane Foam FRP Sandwich Panels for Refrigerated Trucks -

GRP XPS Foam Sandwich Panels for Reefer Trucks

GRP XPS Foam Sandwich Panels for Reefer Trucks -

XPS Foam FRP Plywood for Truck Floors

XPS Foam FRP Plywood for Truck Floors -

PET Film New FRP Facing XPS Foam Panels For Refrigerated Trucks

PET Film New FRP Facing XPS Foam Panels For Refrigerated Trucks