Home > Sandwich Panels > Fiberglass PVC Foam Sandwich Panels

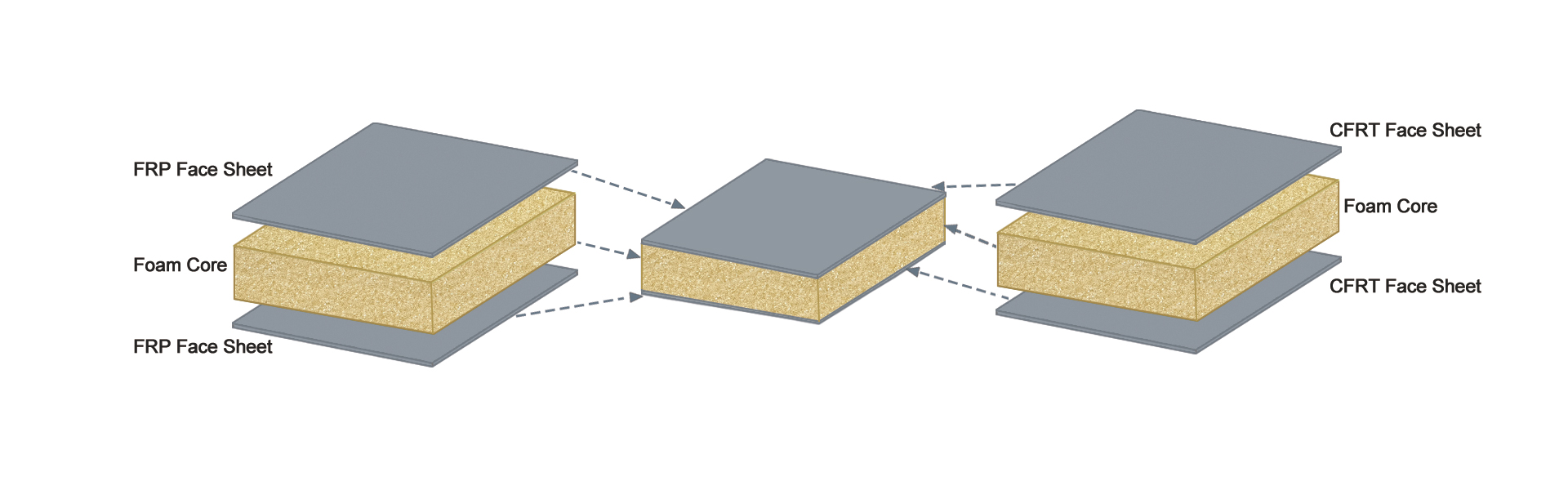

FRP skin PVC foam sandwich panels are a new composite material with upper and lower layers made of fiberglass and a PVC foam core in the middle. The stability of PVC foam combined with the high toughness of FRP has good resistance to water absorption.

PVC foam fiberglass sandwich panels have a large operating temperature range, typically -240℃~80℃, and are resistant to various chemicals. Its fine microporous structure allows for optimal density, resulting in stiffness and durability.

Compared to traditional metal composite panels, fiberglass PVC foam composite panels are lighter, less prone to deformation, easier to install, and have a longer service life. These panels find wide application in various fields, including box trucks, off-road RVs, yachts, public transportation, furniture, and construction.

Basic Specifications

| Skin Material | Thermoset FRP Sheet | Thermoplastic CFRT Sheet |

| Core Material | PVC Foam Core | |

| Skin Thickness | 0.7~5.0mm | 0.4~10mm |

| Length | ≤12m | |

| Width | ≤3.2m | |

| Surface Color | Natural, other colors can be customized | White, black, wood grain, natural |

| Surface Pattern | Glossy, matte, stone, weave, bubble, and imitation leather surface patterns | Glossy, matte |

| Process Option | Embedded reinforcement materials; CNC machining services | |

| Total Thickness | 10~120mm (Customized) | |

FRP VS CFRT

| Skin Material | FRP Sheet | CFRT Sheet |

| Rigidity | Good | Very good |

| Impact Strength | Good | Very good |

| Scratch Resistant | Good | Very good |

| Surface Smoothness | Very good | Good |

| Corrosion Resistance | Very good | Good |

| Lightweight | Good | -35% |

| Tenacity | / | Good |

Features & Benefits

- Extremely lightweight

The material is ultra-lightweight, making it easy to transport and install.

- Super strong

The sandwich structure has high bending strength and impact resistance.

- Corrosion Resistance

Fiberglass has good corrosion resistance and no chemical residues.

- Thermal and sound insulation

PVC foam can effectively reduce heat conduction, and the sound insulation effect is also very good.

- Waterproof and moisture-proof

The sandwich panel has excellent waterproof performance.

- Eco-friendly

Recyclable materials, no harmful gas release.

- Easy processing

The material can be cut, drilled, bonded, and processed according to needs.

Technical Data

| Test Items | Test Standards | Unit | Typical Value | PVC40 | PVC48 | PVC55 | PVC75 | PVC90 | PVC130 | PVC200 | PVC250 |

| Density | ISO 845 | Kg/m3 | Average Range | 40 | 48 43-55 | 60 54-69 | 80 72-92 | 100 90-115 | 130 120-150 | 200 180-250 | 250 225-288 |

| Compression Strength | ISO 844 | N/mm2 | Average Minimum | 0.45 | 0.60 1.50 | 0.90 0.75 | 1.45 1.10 | 2.0 1.7 | 3.0 2.6 | 5.2 4.5 | 6.6 5.3 |

| Compression Modulus | DIN 53421 | N/mm2 | Average Minimum | 41 | 48 35 | 69 55 | 104 80 | 130 110 | 170 145 | 280 240 | 350 280 |

Applications

- Refrigerated truck bodies.

- Cold storage rooms.

- Public transportation.

- Motorhomes.

- Temporary housing.

- Yachts and boats.

- Building facades.

- Industrial equipment enclosures.

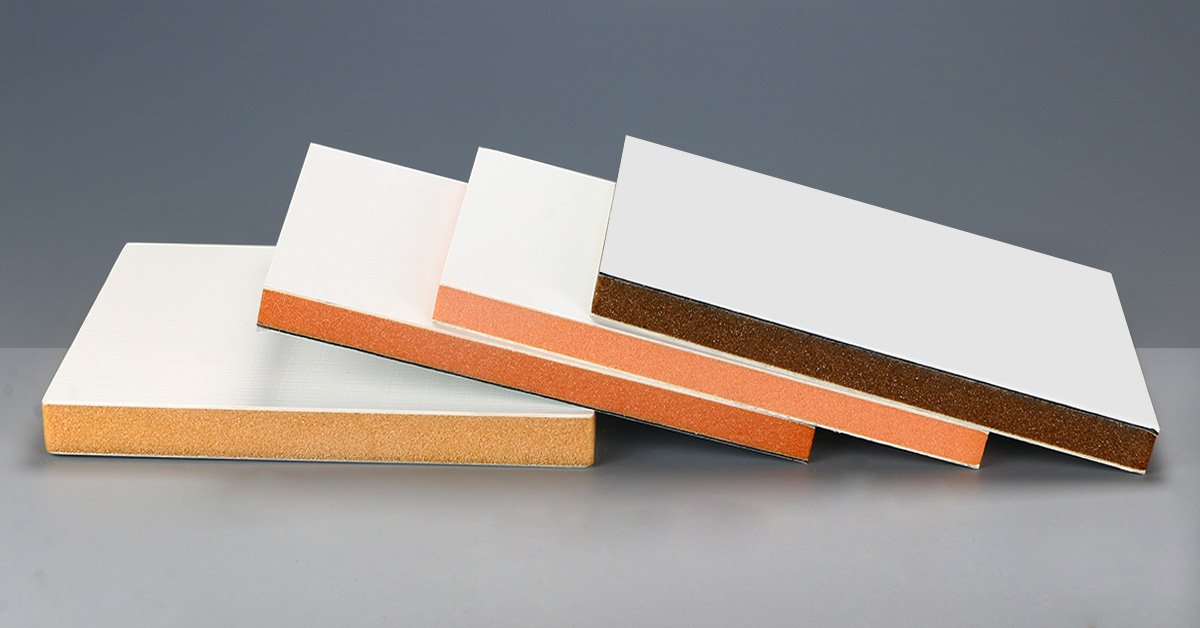

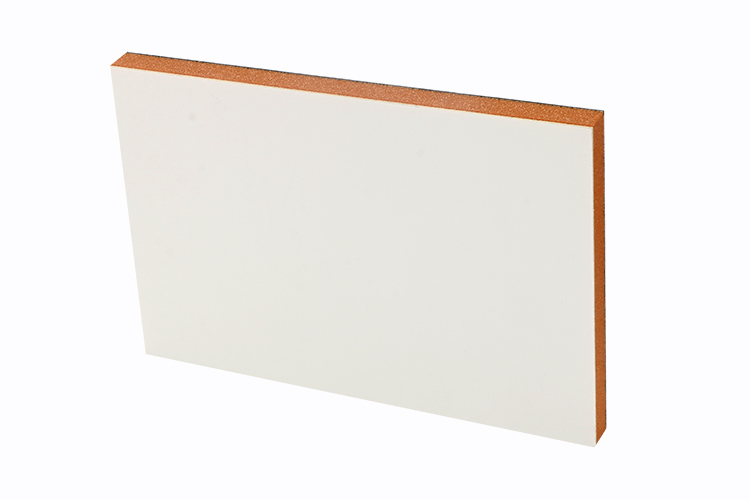

Samples Display

-

BFRP Skin PVC Foam Sandwich Panel

BFRP Skin PVC Foam Sandwich Panel -

PET Film PVC Foam New Fiberglass Sandwich Panel

PET Film PVC Foam New Fiberglass Sandwich Panel -

FRP Aluminum Skin PVC Foam Composite Panel

FRP Aluminum Skin PVC Foam Composite Panel -

PVC Foam Core Fiberglass Sandwich Panel

PVC Foam Core Fiberglass Sandwich Panel -

Fiberglass Facing PVC Foam Panels

Fiberglass Facing PVC Foam Panels -

PP Film PVC Foam New FRP Sandwich Panels

PP Film PVC Foam New FRP Sandwich Panels -

PET Film CFRT Sheet PVC Foam Sandwich Panel

PET Film CFRT Sheet PVC Foam Sandwich Panel -

Carbon Black CFRT PVC Foam Sandwich Panel

Carbon Black CFRT PVC Foam Sandwich Panel