Specifications

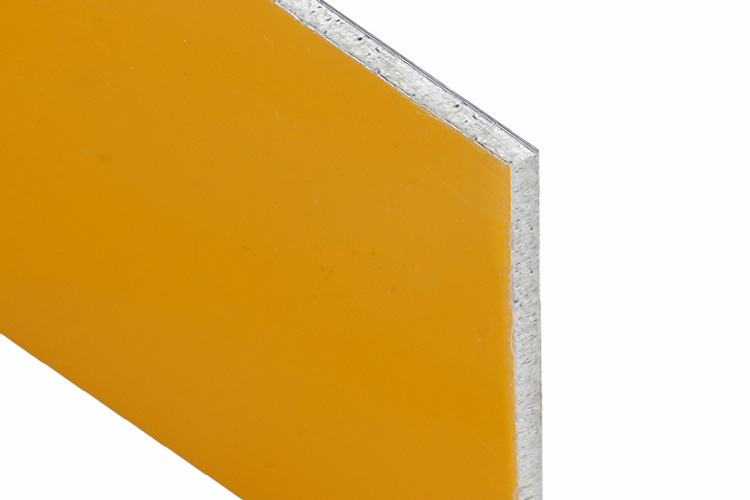

- Thickness: 8mm

- Skin thickness: 0.4mm

- Surface Material: High strength steel

- Core Material: High density PE

- Density: 10kg/㎡

- Flexural Strength: ≥15000psi

- Tensile Strength: ≥13000psi

- Peel-off Strength: 7.5 N/mm

- Penetration Resistance: ≥750kg

Description

What Is Steel Skin HDPE Composite Panel For Trailers?

Steel skin facing high-density PE composite panel is a material used for trailer bodies that combines the advantages of steel skin and high-density polyethylene (PE). Commonly used in the construction of van, trailer and other types of trailer bodies to provide strength, durability and lightweight properties.

Features

- Strength and Stiffness

The steel skin enhances the overall strength and stiffness of the composite panel, allowing it to withstand heavy loads and external impacts.

- Corrosion resistance

Steel skin surface coverage provides protection against corrosion and oxidation, extending the service life of the panel.

- Impact resistance

The high-density polyethylene (PE) layer can provide a certain degree of cushioning and impact resistance, reducing the impact on the cargo during a collision.

- Ease of processing

Due to its construction, this composite panel is relatively easy to process into a variety of shapes and sizes to suit different types of body design needs.

- Beautiful appearance

The appearance of steel skin can provide the car body with a neater and more professional appearance, enhancing the appearance texture and brand image of the vehicle.