Home > Sandwich Panels > Fiberglass Honeycomb Sandwich Panels

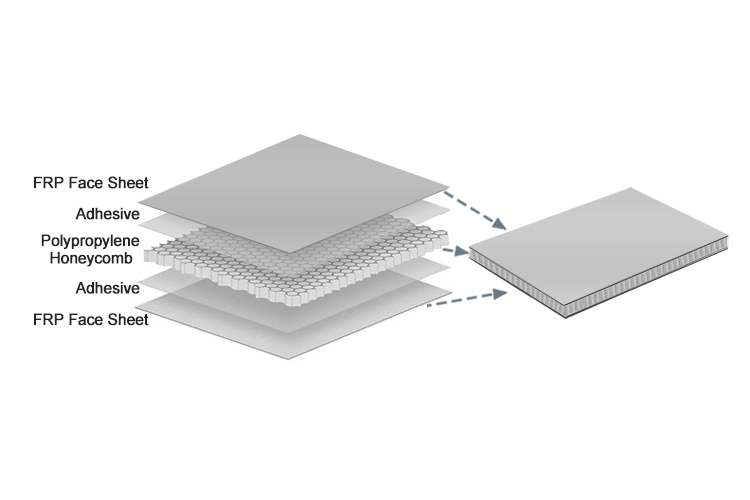

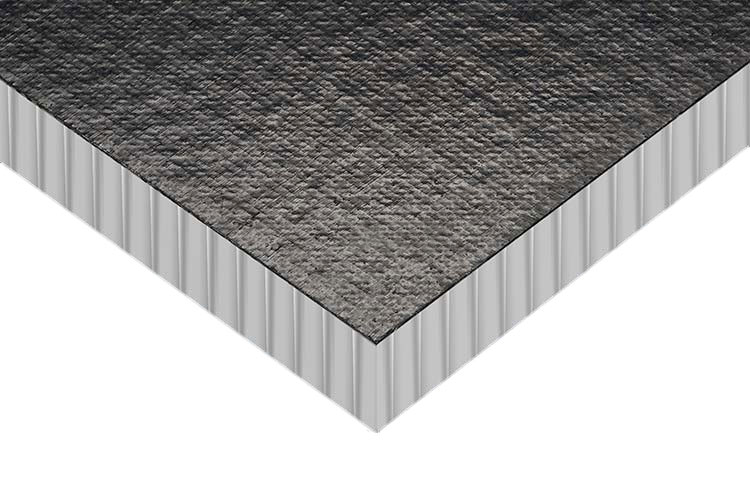

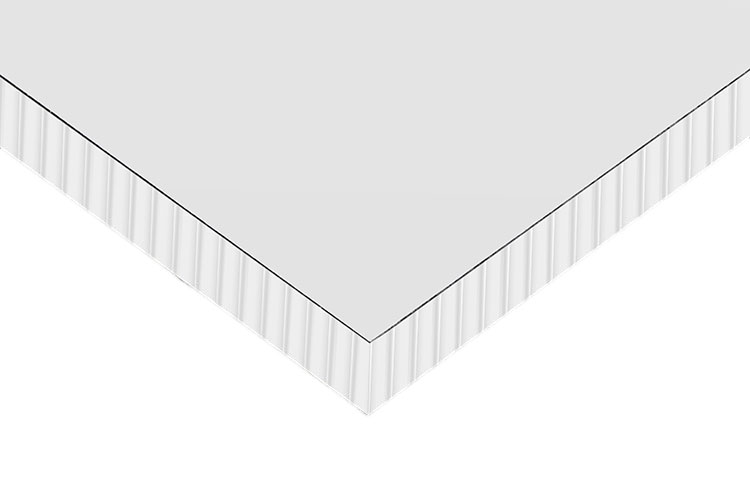

A fiberglass honeycomb sandwich panel is a composite material consisting of an FRP surface layer and a honeycomb core. FRP has corrosion resistance and anti-aging properties, and the honeycomb structure remains lightweight while providing strength.

Its excellent mechanical properties, insulation properties, and flame retardant properties make it widely used in vehicle manufacturing, architectural decoration, advertising production, electrical equipment, and other fields.

Structure of Honeycomb Sandwich Panel

- FRP Layer: A gel coat covers the surface and allows for embossing into different texture patterns.

- Reinforcement layer (optional): Made of high-temperature-resistant glass fiber mat plastic. It acts as an isolation layer between the FRP material and the PP honeycomb core material, bonding them more closely and enhancing the strength of the honeycomb panel.

- Polypropylene Honeycomb Core: Polypropylene honeycomb core is available in different pore sizes and thicknesses. Honeycomb cores of different densities provide different properties: such as compressive strength, flexural strength, etc.

Performance of Fiberglass Honeycomb Sandwich Panel

- Lightweight

Due to its honeycomb structural core, Fiberglass honeycomb panels are extremely lightweight, providing excellent strength and stiffness at a relatively low weight ratio.

- High Impact Resistance

It withstands general impacts without damaging the surface.

- Higher Bending Resistance

The hardness of FRP is higher, and FRP PP honeycomb panels will not undergo large deformation.

- Corrosion resistance

The surface layer of FRP has good corrosion resistance and is suitable for use in humid and corrosive environments.

- Easy to process

Compared with metal materials, FRP honeycomb panels are easier to process in various shapes and sizes.

Specifications

| Skin Material | Thermosetting Resin FRP Sheet |

| Core Material | Polypropylene Honeycomb |

| Total Thickness | 10~75mm |

| Thickness Tolerance | ±0.5mm |

| Skin Thickness | 0.3~5mm |

| Core size | 6~16mm |

| Width | ≤3.2m |

| Length | ≤12m |

| Honeycomb Density | 80~200kg/m3 |

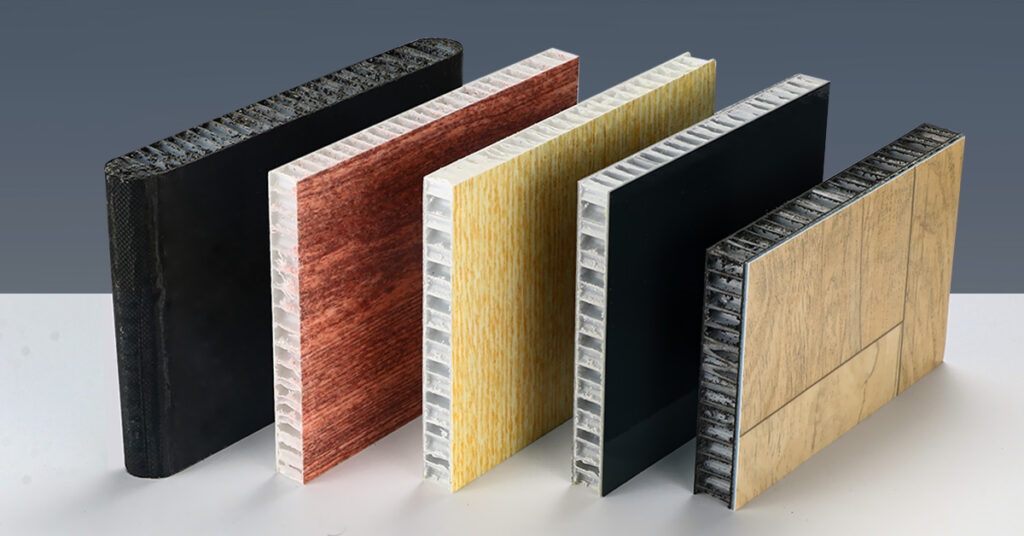

| Surface Treatment | High gloss, matte, embossed, etc. |

| Surface Color | RAL color. |

| Performance | Anti-UV, flame retardant. |

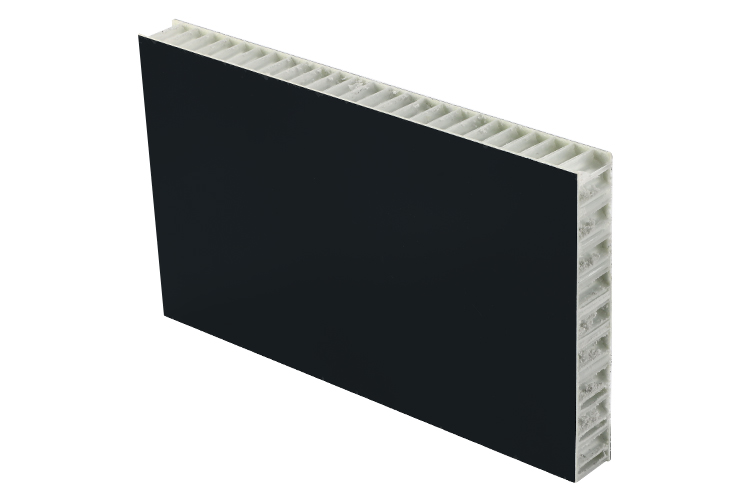

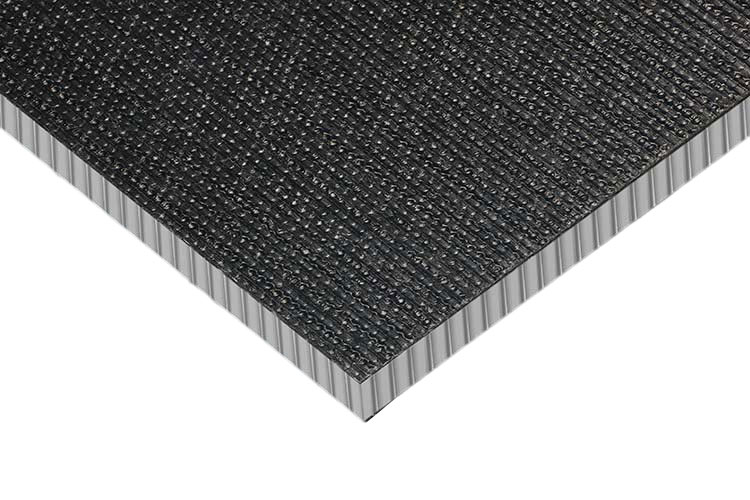

Surface Treatment

The GRP surface can be processed into various texture patterns such as glossy and matte, and can also be coated with other materials (such as gravel).

Applications

- Box trucks: wall panels, floors, roof panels, partitions for trucks and RVs.

- Ships: cabin partitions, room floors.

- Construction: building formwork, exterior wall composite panels, ceilings.

- Industry: art centers, exhibition halls.

- Furniture: tables, storage boxes, cabinets, bed boards.