Home > Sandwich Panels > Plywood Facing Foam Sandwich Panels

Birch plywood sandwich panels are a new type of composite material, usually composed of a foam core sandwiched between two layers of plywood.

This design combines the strength and durability of birch plywood with the lightweight and insulating properties of a foam core.

It has the characteristics of heat insulation, moisture resistance, and aesthetics. It is widely used in many fields such as construction, furniture, packaging, etc.

Features of Birch Plywood Foam Sandwich Panels

- Outer layer

The outer layer of traditional plywood is pure plywood, which is easily affected by moisture. To solve this problem, we cover one side of the composite board with a layer of fiberglass or aluminum alloy, which can effectively prevent the plywood from getting damp and improve its durability.

- Aesthetic

Plywood surfaces are available in a variety of textures and colors to suit different design styles.

- Easy to process

We can customize according to customer requirements, including size, shape and surface treatment options.

- Good thermal insulation

We use high-quality ultra-low thermal conductivity foam materials with lower density and lighter weight. which helps to improve the energy efficiency of the building and reduce energy consumption for air conditioning and heating.

- Lightweight and durable

Birch plywood foam sandwich panels are lighter in weight but not less strong, which makes them more convenient to transport, install and use. At the same time, birch plywood has good durability and long service life, and can maintain its stable performance for a long time.

- High strength and stability

Plywood itself has a high strength, stable structure, is not easy to deform or crack, and can withstand large loads and impacts. After adding the foam interlayer, the bending strength and overall stability of the board are further enhanced.

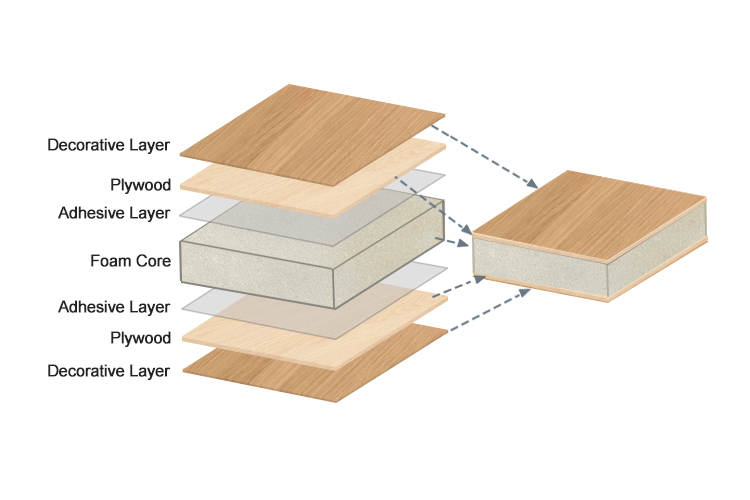

Structure Schematic

- Skin material: Plywood(Poplar, birch, oak, pine, eucalyptus, beech, etc.).

- Core material: XPS/PET/PU/PVC foam board.

- Length: within 12m.

- Width: within 3.2m.

- Thickness: 50~150mm.

Applications of Birch Plywood Foam Sandwich Panels

Technology and Capabilities

- We have a team of engineering designers with over 20 years of experience

- Multiple panel production lines to meet the manufacturing of various specifications.

- Advanced processing production lines can achieve high precision, high efficiency, and large-scale production.

If you would like more information about our birch plywood panels or would like a quote, please contact us.