Home > Markets > Anti Slip Scaffolding Board

Scaffolding boards frequently support the construction and maintenance of structures like buildings and bridges. However, the unique challenges of high-altitude operations lead to occasional safety accidents, such as falls. Therefore, many people increasingly focus on finding ways to enhance scaffolding safety.

Conventional scaffolding boards are mostly made of aluminum alloy or plywood. However, their shortcomings are also very obvious. For this purpose, Carbody specially developed and customized anti-slip thermoplastic PP honeycomb panel scaffolding.

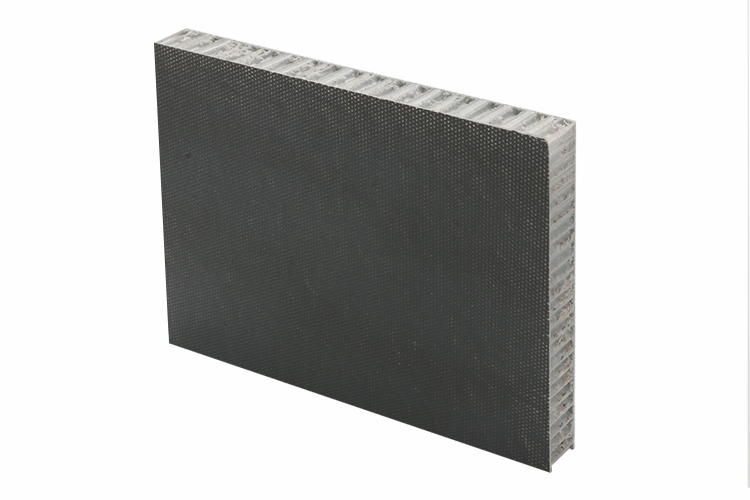

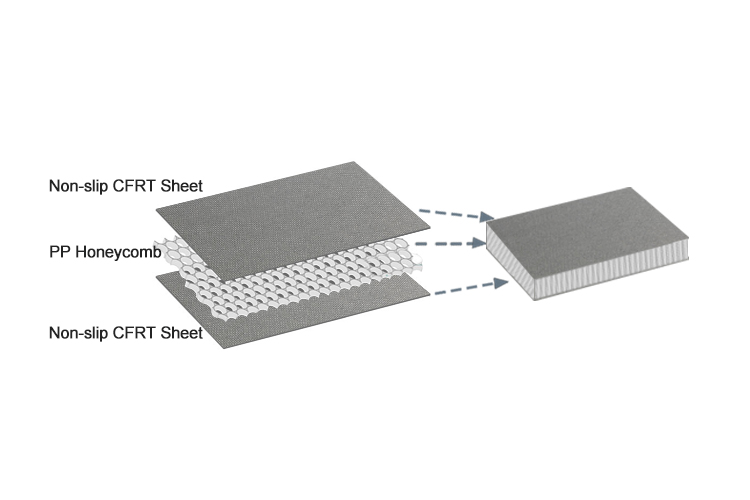

Structure of Anti-slip Scaffolding Board

PP honeycomb core is a representative of lightweight materials. The new FRP skin gives it aesthetics and reinforcement. It has structural support that is not inferior to plywood and aluminum alloy.

Fiberglass wall panels allow for easy assembly with profiles, which enhances production efficiency. They weigh less and are easier to transport than traditional steel or plywood siding.

Features of Anti-slip Scaffolding Board

The new fiberglass anti-slip scaffolding board combines a fiberglass skin with a PP honeycomb core material. The surface layer is a continuous fiberglass thermoplastic composite sheet. Flame-retardant, corrosion-resistant, UV-resistant, and has a hard, non-slip texture.

- Anti-corrosion, non-rusty

- High strength

- low weight, low cost to transit and maintain

- Anti-slippery and safety

- Anti-aging

- Wear-resistant

- Insulation

- Easy installation

- Environmental friendly, non-toxic, and harmless

Comparison of Different Scaffolding Board Materials

| Property | New FRP | Timber | Metal |

| Weight | Light | Middle | Heavy |

| Water Resistance | Resistant | Absorbable | Rusty |

| Chemical Resistance | Resistant | Not resistant | Not resistant |

| Deformation | Hard | Easy | Hard |

Basic Info.

| Type | New Fiberglass Honeycomb Sandwich Panel for anti-slip scaffolding Board |

| Skin Material | Anti-skid New FRP Sheet:0.7~3mm |

| Core Material | PP(polypropylene) Honeycomb |

| Color | White, Black, Gray, Orange, or Customized |

| Length | Within 12m |

| Width | Within 3.2m |

| Flexural Strength | ≤135MPa |

| Areal Weight | ≤5486g/m2 |

| Density | 80~140kg/m³ |

| Anti-ultraviolet grade | F1 |

| Total Thickness | 15.25-15.50mm |

| Applications | Scaffolding |

Our Unique Advantages

- New thermoplastic production line

Our factory has the latest international thermoplastic production line. We can produce high-quality continuous fiber-reinforced thermoplastic panels at ultra-high speeds.

- Highly modular

Our scaffolding adopts a modular structure and is quick and easy to assemble. One person can complete the assembly in a short time.

- More aesthetic

Flat-head nuts and bolts securely connect the pedals. The scaffolding features a smooth and aesthetically pleasing surface, enhancing safety.

- High load capacity

Scaffolding withstands potential toppling and provides unmatched strength and stability.

- High-quality materials

It is the combination of high-quality thermoplastic PP honeycomb panels and 304 food-grade high-strength stainless steel (brackets, edge strips, pedal hooks).

Transportation and Cooperation

We cooperate with land transportation and sea transportation in many places around the world. And develop a special plan for each packaging and transportation.

We have sufficient capabilities to meet the requirements of scaffolding dealers and wholesalers around the world.