Home > Sandwich Panels > Aluminum Foam Sandwich Panels

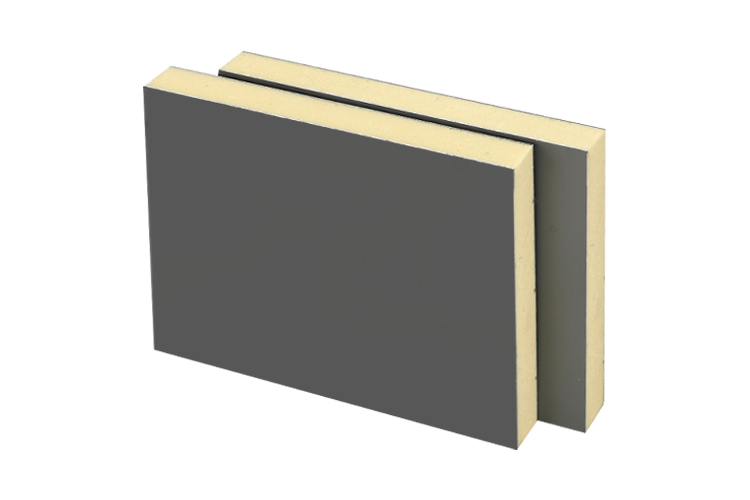

Foam aluminum sandwich panels are composite materials made of aluminum and foam core materials. Their structural design allows them to maintain strength while being waterproof, corrosion-resistant, heat-insulating, and beautiful.

They are widely used in architectural decorative wall panels, aerospace, and automotive fields. The unique properties of foam aluminum sandwich panels make them an indispensable material in modern industry.

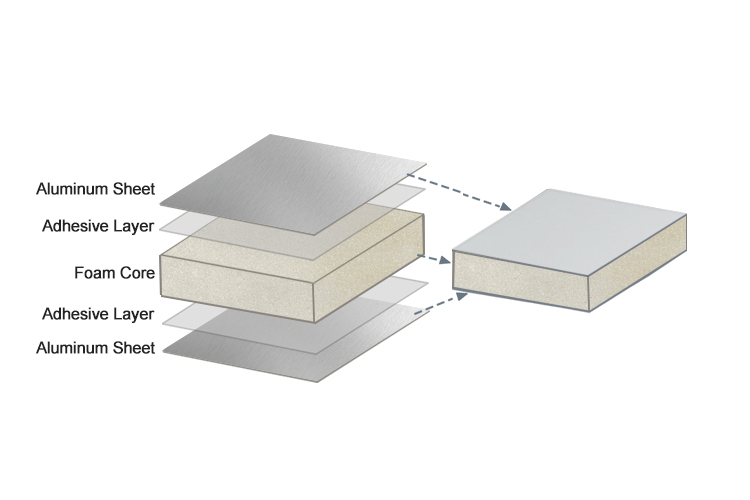

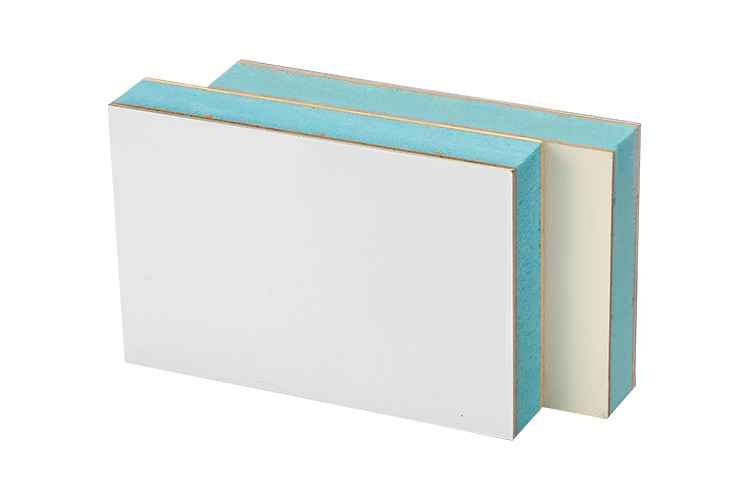

Structural Diagram of Aluminum Foam Sandwich Panel

- Aluminum Facing

It provides the appearance, durability, and corrosion resistance of the sandwich panel. Different surface treatments, such as painting, anodizing, or coating, can enhance its aesthetics and protective properties.

- Core

Common materials include XPS, PU, PET, PVC, etc. The foam core is lightweight, thermally insulating, and shock-absorbing, which helps improve the sandwich panel’s insulating properties and reduce its overall weight.

Advantages of Aluminum Foam Sandwich Panels

- Lightweight

Compared to traditional materials, aluminum foam sandwich panels are lighter in weight and easier to transport and install.

- High strength

Aluminum foam sandwich panels are very strong and can withstand high pressure.

- Thermal Insulation

Foam core material has good thermal and sound insulation properties.

- Corrosion resistance

Aluminum material makes it have excellent corrosion resistance and is suitable for use in harsh environments.

- Eco-friendly materials

Foam aluminum sandwich panels can be recycled and reused, complying with modern environmental regulations.

Specifications

| Aluminum sheet thickness | ≥0.1mm |

| Core Material | XPS/PET/PU/PU/PVC foam |

| Total Thickness | 10~120mm |

| Width | 800~2600mm |

| Length | ≤12m |

| Aluminum Grades | 1050, 1060, 1100, 1145, 1200, 1230, 1350, 2011, 2014, 2017, 2018, 2124, 2219, 2319, 3003, 3004, 3105, 5005, 5052, 5083, 5086, 6061, 6063 ,7075, 7050, 7049, 710 0, 8006, 8111, 8079, etc |

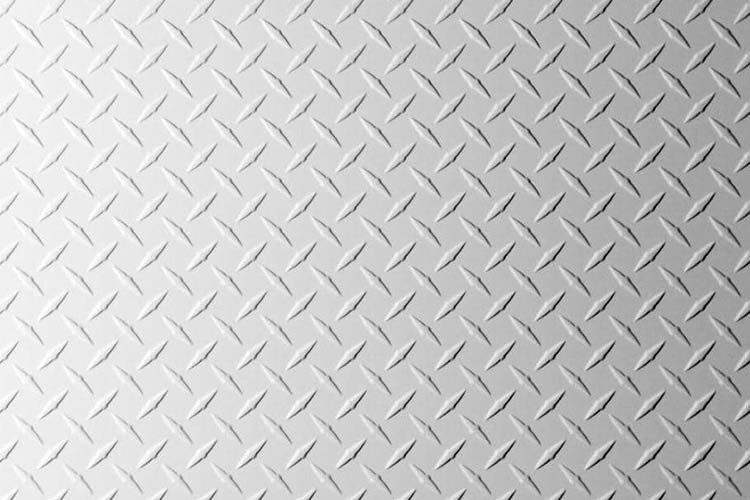

| Aluminum Surface Treatment | Sandblasting, polishing, glossy, matte, embossed, fluorocarbon coating, anodizing, etc |

| Aluminum Surface Color | RAL color, or customized pattern |

Surface Treatment

Application Fields

Foam core aluminum skin sandwich panels are widely used in many fields due to their lightweight, strong, thermal insulation and corrosion resistance properties:

Vehicles

- Dry cargo trucks

- Dry cargo trailers

- Fire trucks

- Ambulances

- Buses

- Subways

- RVs

Constructions

- Exterior wall decoration

- Ceiling system

- Interior wall panels

- Partitions

Samples

-

Aluminum Plywood Facing Foam Composite Panel

Aluminum Plywood Facing Foam Composite Panel -

Aluminum FRP Facing PVC Foam Composite Panel

Aluminum FRP Facing PVC Foam Composite Panel -

Aluminum Facing PET Foam Sandwich Panel

Aluminum Facing PET Foam Sandwich Panel -

Polyester Aluminum XPS Foam Sandwich Panel

Polyester Aluminum XPS Foam Sandwich Panel -

Aluminum Plywood Skin XPS Foam Sandwich Panel

Aluminum Plywood Skin XPS Foam Sandwich Panel -

Aluminum Plywood Skin XPS Foam Composite Panel

Aluminum Plywood Skin XPS Foam Composite Panel -

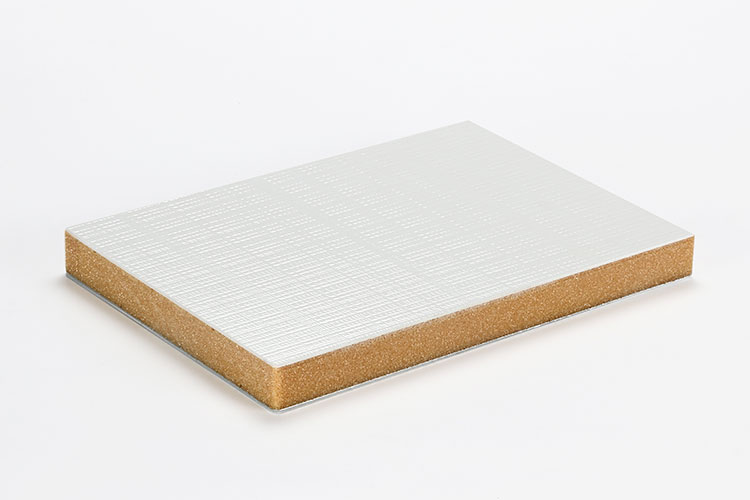

Fabric Pattern FRP Skin PVC Foam Composite Panel

Fabric Pattern FRP Skin PVC Foam Composite Panel -

Anti-slip Aluminum Skin PVC Foam Sandwich Panel

Anti-slip Aluminum Skin PVC Foam Sandwich Panel

If you are interested in aluminum foam sandwich panels, welcome to contact us for more information and customized services.