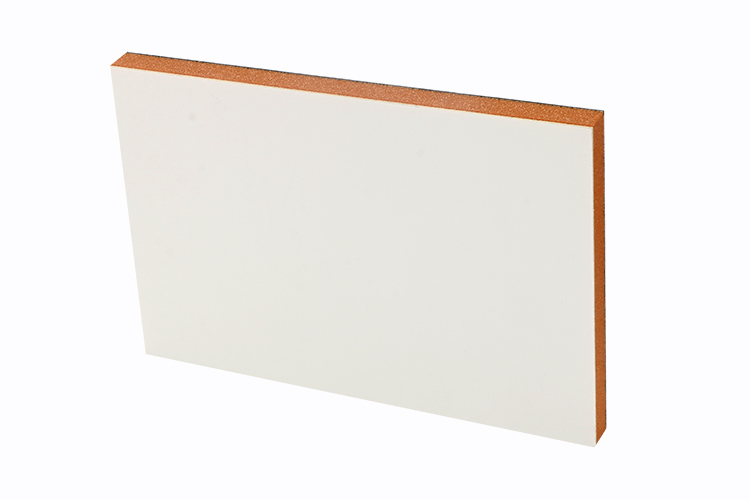

- Thickness: 20mm

- Additive: Carbon black

- Upper Skin: PET film + CFRT Sheet

- Core Material: PVC foam

- Lower Skin: PP film CFRT Sheet

PET film CFRT skin PVC foam panel is a new type of composite material. The upper and lower layers are made of fiberglass, and the middle layer is PVC foam core material. We also covered the surface with a layer of PET film to make the entire panel smoother and more aesthetic.

This type of panel is widely used in different fields such as box trucks, off-road RVs, yachts, public transportation, furniture, and buildings.

Panel Features

- Waterproof and corrosion-resistant: PET film and CFRT skin are both waterproof and chemical-resistant materials. Products made of this kind of sheet can have a longer service life.

- Lightweight and strong: The stability of PVC foam core combined with the high strength of GRP sheet makes it one of the ideal materials for lightweight solutions.

- Good weather resistance: This type of panel can also withstand a wide temperature range (-240℃~80℃). It is UV-resistant and flame-retardant, which can adapt to various environments.

- Good thermal insulation effect: PVC foam maintains its own strength while also having good thermal insulation properties. Truck bodies and buildings made of it can be better insulated.

- Easy to process: It can be cut and processed according to your specific needs. It has good formability and is not easy to deform.