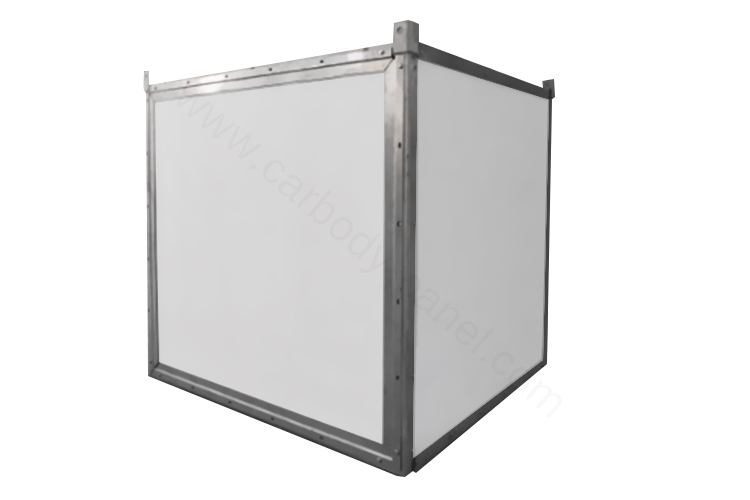

Cooling towers are used to remove heat from the incoming water and maintain the optimal temperature for further processes. They are heat removal devices that use water to transfer process waste heat to the atmosphere and are commonly used in wastewater treatment plants.

The operating principle of industrial cooling towers is to remove heat from water by evaporating a small portion of the water that is recirculated through the device.

Cooling towers are used to remove heat from the incoming water and maintain the optimal temperature for further processes. They are heat removal devices that use water to transfer process waste heat to the atmosphere and are commonly used in wastewater treatment plants.

The operating principle of industrial cooling towers is to remove heat from water by evaporating a small portion of the water that is recirculated through the device.

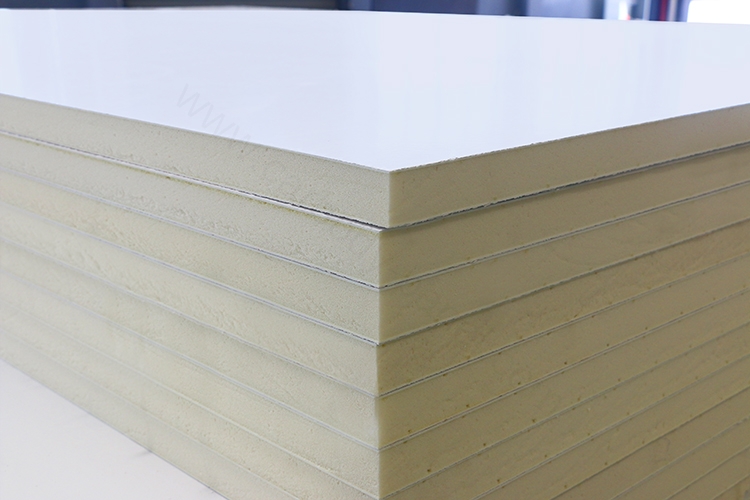

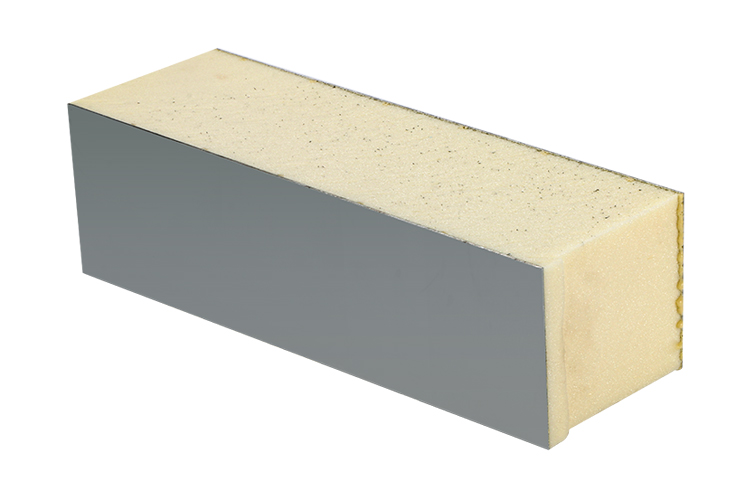

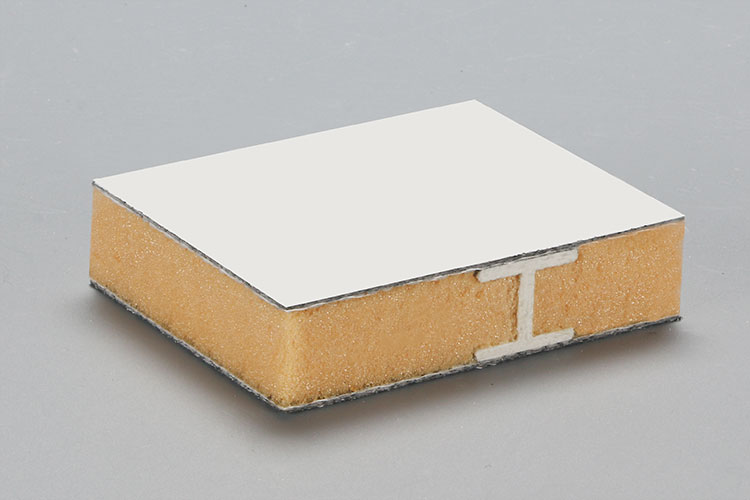

Panel Structure

- Upper skin: 1mm matte white FRP skin

- Core layer: 28mm Polyurethane (PU) foam

- Lower skin: 1mm matte white FRP skin

Panel Specifications

- 2070×1435×30mm

- 2070×1920×30mm

Product Features

- Insulation: Polyurethane (PU) foam is a closed-cell foam with extremely low thermal conductivity and excellent thermal conductivity. Therefore, it can help cooling towers evaporate water faster and better.

- High-strength: FRP Skin PU Foam Sandwich Panels can withstand certain impacts and pressures and provide sufficient structural support.

- Corrosion-resistant: The fiberglass skin of this kind of panel is not easily corroded by chemicals such as water, acid, and alkali, which can be used for a long time in the operating environment of the cooling tower.

- Weather-resistant: FRP skin can better resist ultraviolet rays, making the cooling tower less likely to fade and age, and is very suitable for outdoor use.

- Easy to Process: We can customize products according to your specific needs, including cutting, molding, and connection.

Our Advantages

- Fully automatic composite panel production line We have a composite panel production line covering an area of 5,000 square meters, with internationally advanced production equipment, which can meet the requirements of large-scale and high-precision production.

- Five-axis CNC machining service TOPOLO provides high-precision CNC machining for various composite panels. We use advanced 5-axis synchronous machining to meet the processing needs of various high-standard materials.

- Professional engineer team We have a professional design team and manufacturing team, who have been deeply involved in the application field of thermal insulation composite panels for many years. We can design drawings according to your needs and efficiently complete the actual construction.