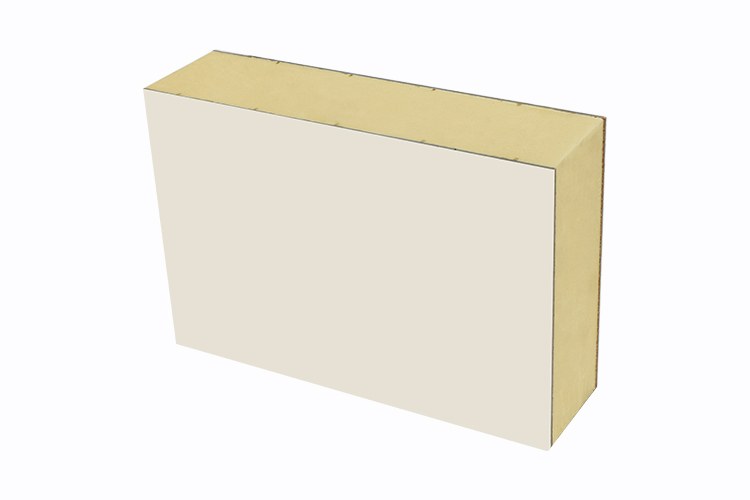

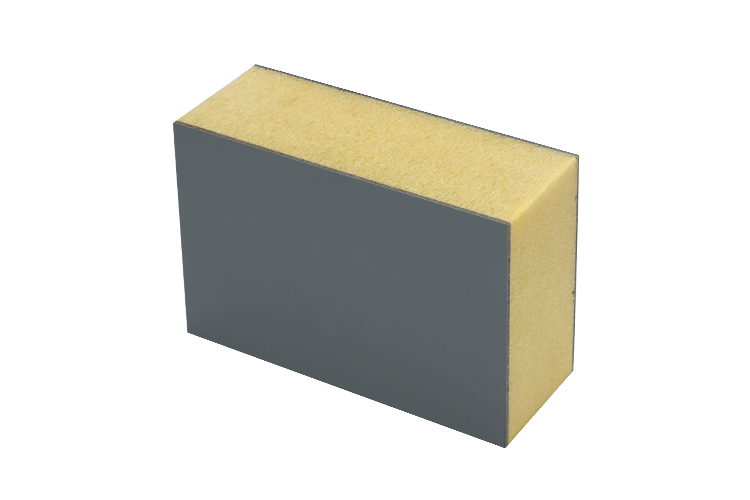

Fiberglass XPS Foam Sandwich Panel

Thermal Insulation | Moisture-proof | Pressure-resistant | Easy to Process

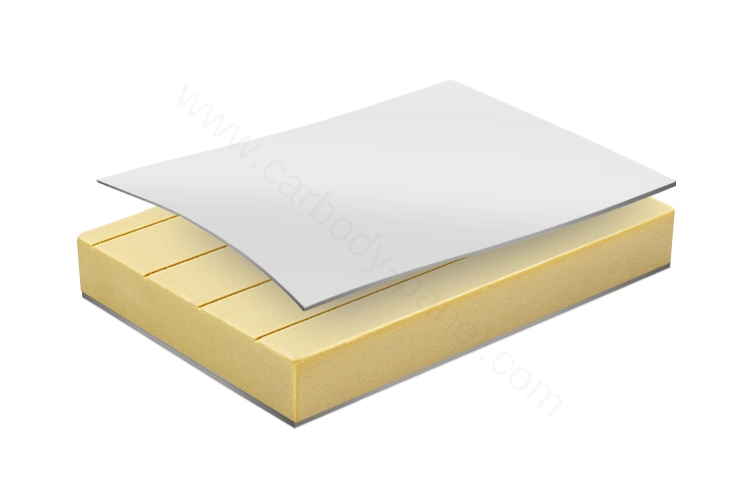

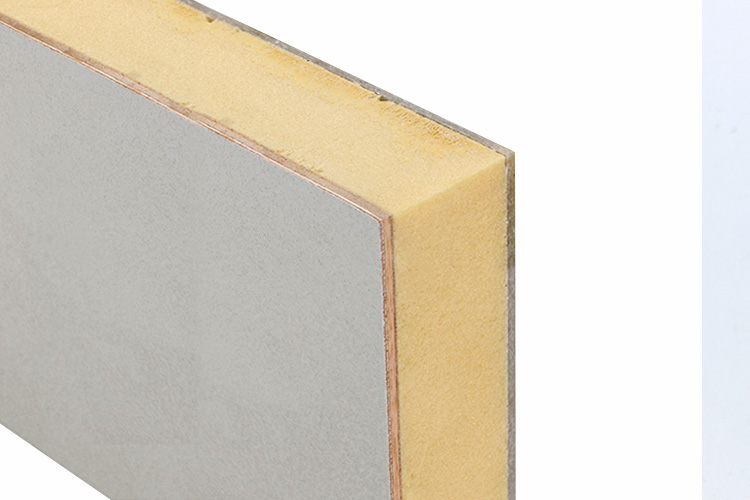

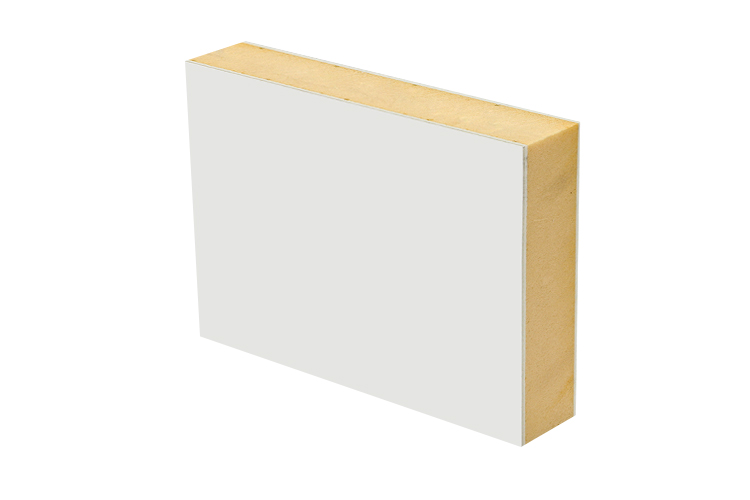

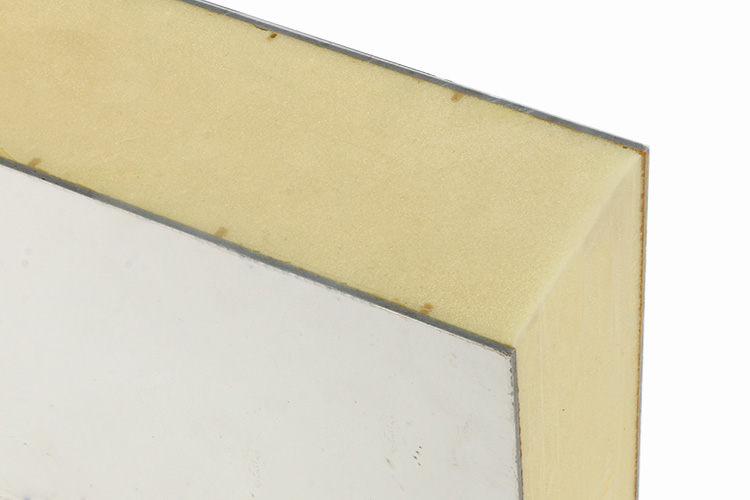

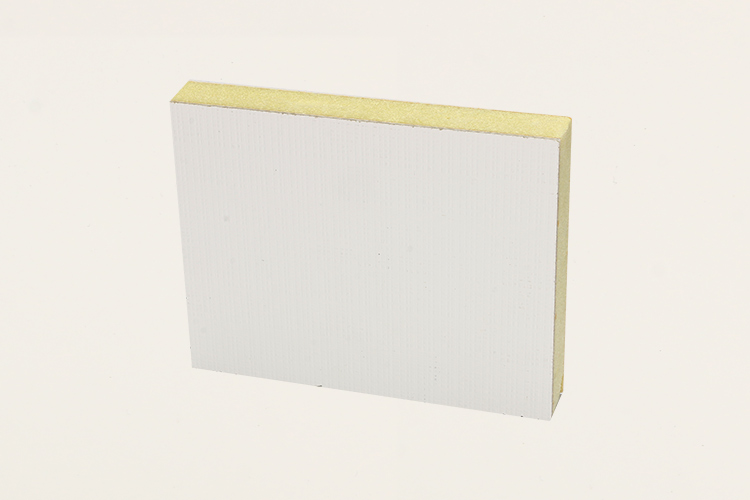

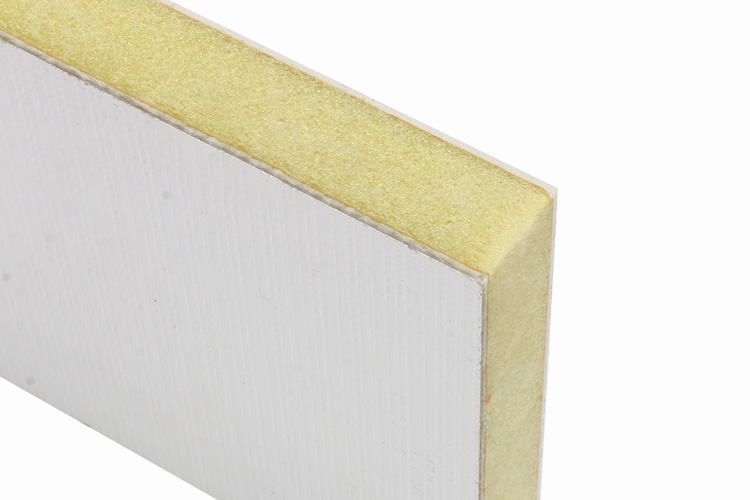

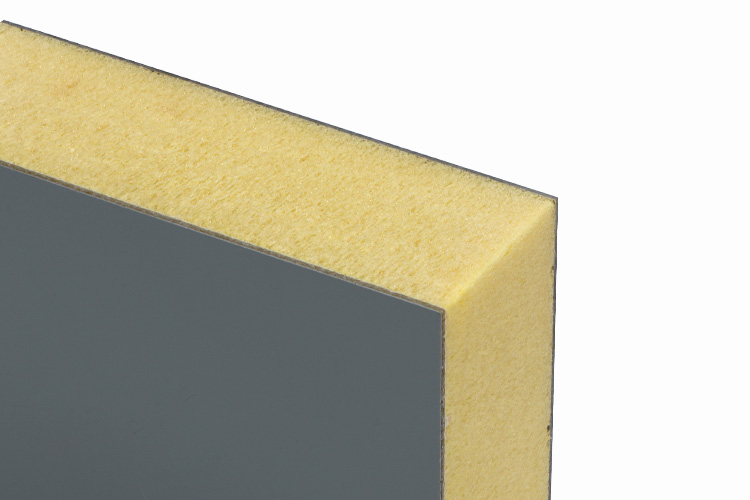

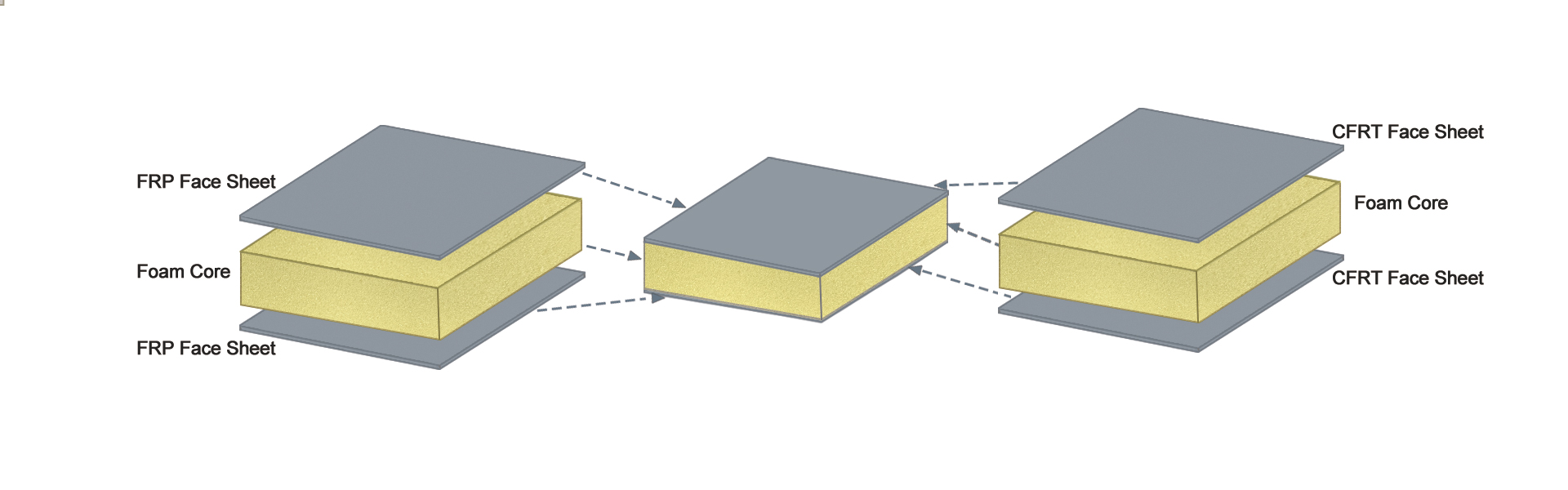

The XPS foam fiberglass sandwich panel is composed of FRP skin and XPS foam. The XPS foam exhibits excellent insulation performance, effectively preventing heat conduction to achieve insulation and heat preservation. It is also highly durable, capable of withstanding pressures of up to 15-25 psi. The fiberglass-reinforced plastic (FRP) skin is made of short glass fibers and thermosetting resin, making it waterproof, moisture-resistant, and smooth-surfaced. The combination of these two materials results in a composite panel that is lightweight yet strong, possessing higher compressive strength than wood fiber and plywood. It is an ideal choice for constructing exterior walls, dry goods trucks, camper vans, and more.

Basic Specifications

| Skin Material | Thermoset FRP | Thermoplastic CFRT |

| Core Material | XPS Foam Core | |

| Skin Thickness | 0.7~5.0mm | 0.4~10mm |

| Length | ≤12m | |

| Width | ≤3.2m | |

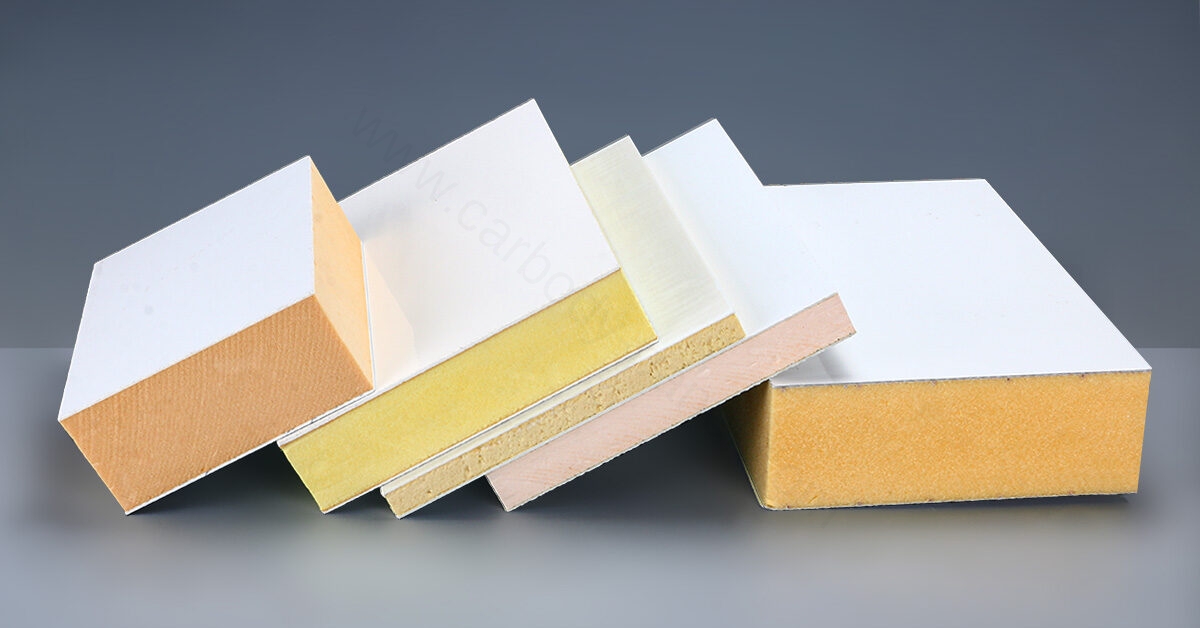

| Surface Color | Natural, other colors can be customized | White, black, wood grain, natural |

| Surface Pattern | Glossy, matte, stone, weave, bubble, and imitation leather surface patterns | Glossy, matte |

| Process Option | Embedded reinforcement materials; CNC machining services | |

| Total Thickness | 10~120mm (Customized) | |

FRP VS CFRT

| Skin Material | FRP | CFRT |

| Rigidity | Good | Very good |

| Impact Strength | Good | Very good |

| Scratch Resistant | Good | Very good |

| Surface Smoothness | Very good | Good |

| Corrosion Resistance | Very good | Good |

| Lightweight | Good | -35% |

| Tenacity | / | Good |

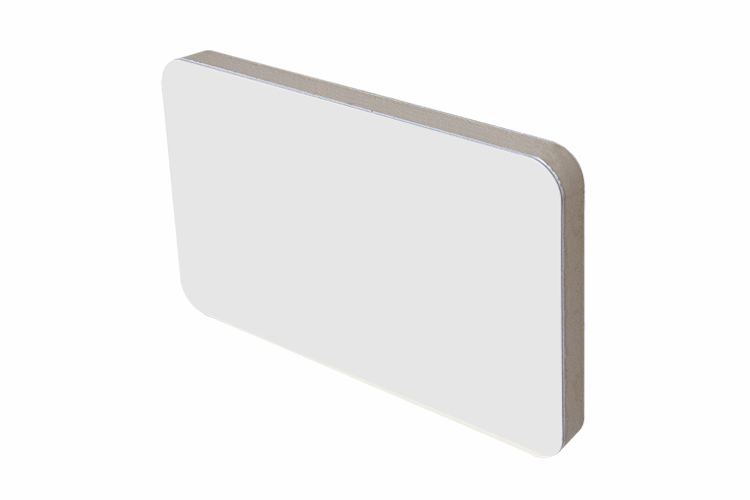

XPS Foam Sandwich Panel Samples

Features & Benefits

Technical Data

| Item | Standard | Unit | Value |

| Density | GB T 10801.2-2002 | kg/m3 | 35 to 40 |

| Thickness | / | mm | Customizable |

| Thermal Conductivity | GB T 10801.2-2002 | W/M·K | 0.028 |

| Compression Strength | GB T 10801.2-2002 | KPa | ≥200 |

| Water Absorption Rate | GB T 10801.2-2002 | L/MIN.m.m | ≤0.01 |