RV panels occupy a core position in the overall design of RVs. RV panels not only affect the appearance of the vehicle, but are also directly related to the service life, comfort, and safety of the RV. Selecting high-quality RV panel materials is the key to ensuring that the RV can operate stably in a variety of environments.

Features of RV Panels

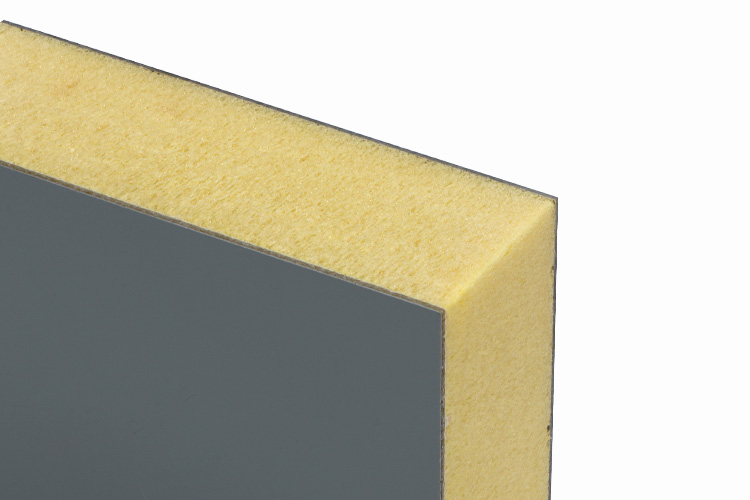

The fiberglass layer enhances the panel’s tensile, compressive, and impact resistance, ensuring that the RV maintains its strength and durability throughout long journeys.

A high-quality foam core has excellent thermal insulation, helping the RV maintain a comfortable temperature in various extreme weather conditions.

The combination of fiberglass and foam makes the panels extremely lightweight, which reduces the overall weight of the RV and increases fuel efficiency.

The outer layer of fiberglass has been specially treated to be waterproof, anti-corrosive, and anti-ultraviolet, suitable for different climatic conditions.

The sandwich panels are easy to process and can be customized according to the RV structure.

CKD RV Panel Services

Carbody provides customized CKD caravan services, including design, material selection, processing and assembly, etc.

- Size: Sandwich panels of various sizes can be precisely customized based on the specific structure of the RV.

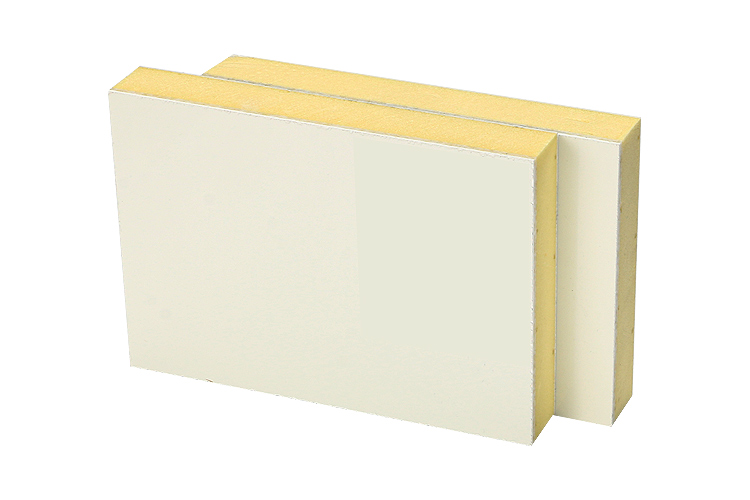

- Color: Available in a variety of color schemes to ensure the panels match the overall design of your RV.

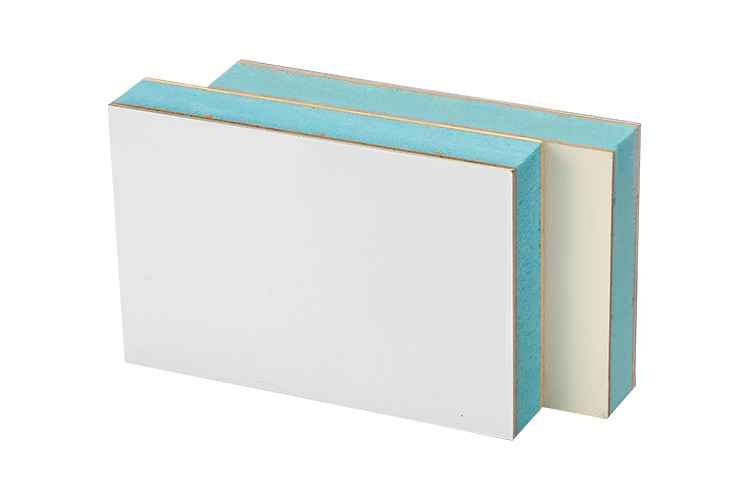

- Material: Different types of foam or fiberglass layers are available to adapt to different usage environments.

- Specific functions: such as anti-oil, anti-scratch, anti-UV, etc.

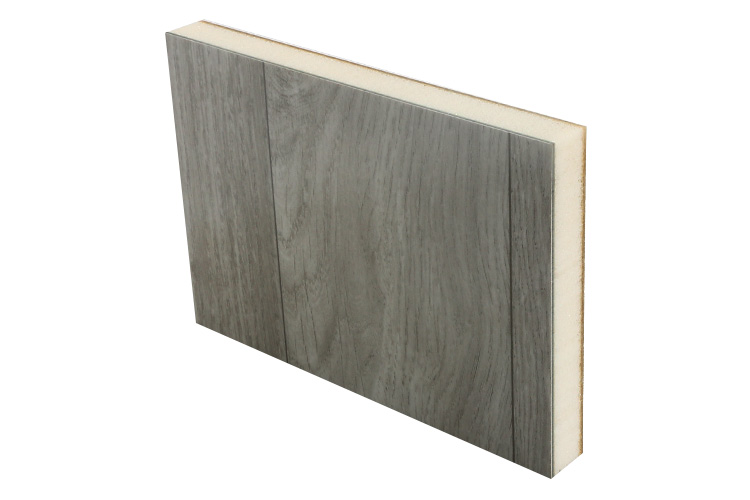

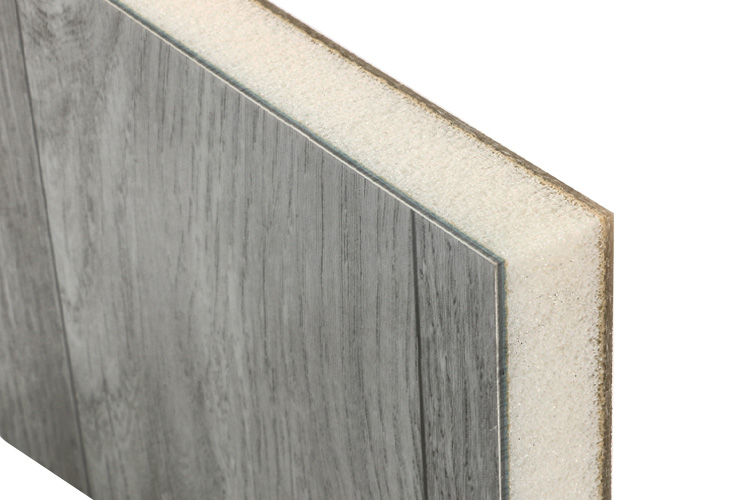

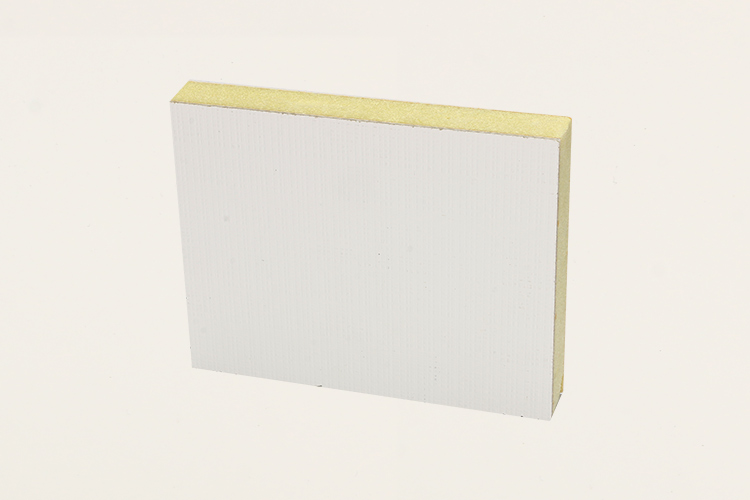

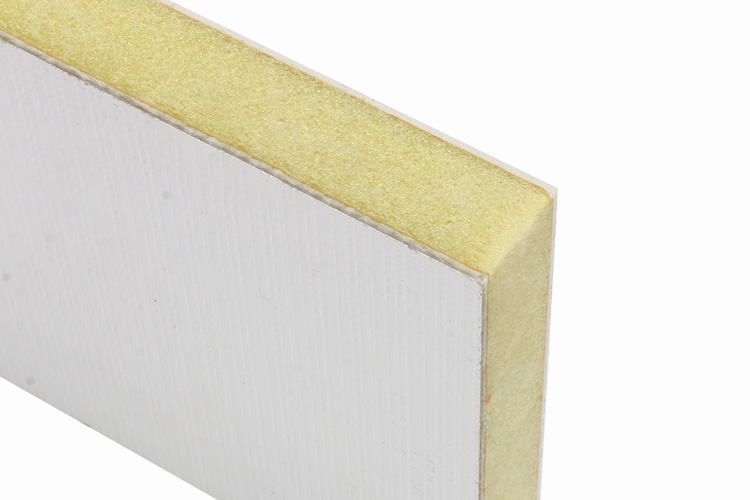

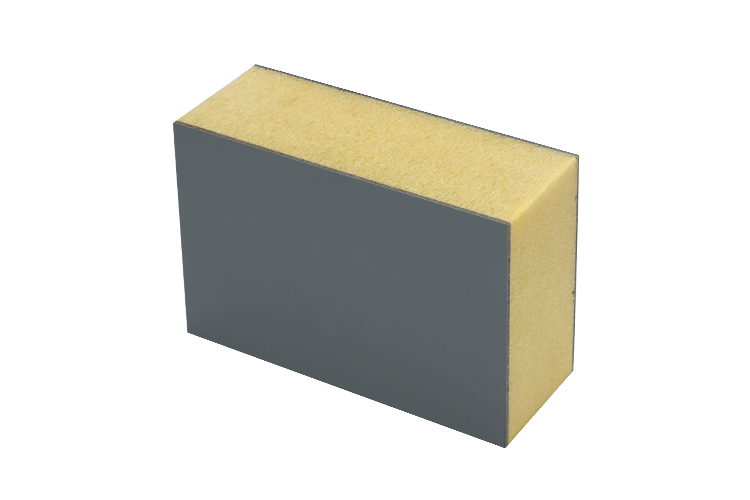

Structure

- Skin material: High-gloss gel coat FRP sheet (thickness 1.8~3.0mm).

- Surface Color: RAL color series.

- Core material: XPS foam (10~120mm).

- Length: within 12m.

- Width: within 3.2.

- Flame Retardant: B2.

- Anti-ultraviolet: F1.

Our Quality Inspection

We improve our professionalism through continuous innovation and ensure that product performance meets industry standards. We have advanced laboratories and sophisticated testing equipment to conduct strict quality testing on RV panels, including strength testing, weather resistance testing, and waterproof performance evaluation, to ensure that each panel can withstand the test of actual use.

Samples

We provide a variety of RV composite panel materials, combinations of various core materials, and skin materials. Such as XPS, PET, PU, PVC, EPP foam core composite panels, or PP honeycomb core composite panels

For more information about our fiberglass foam sandwich panels for RVs, or to customize your solution, please contact our professional team.