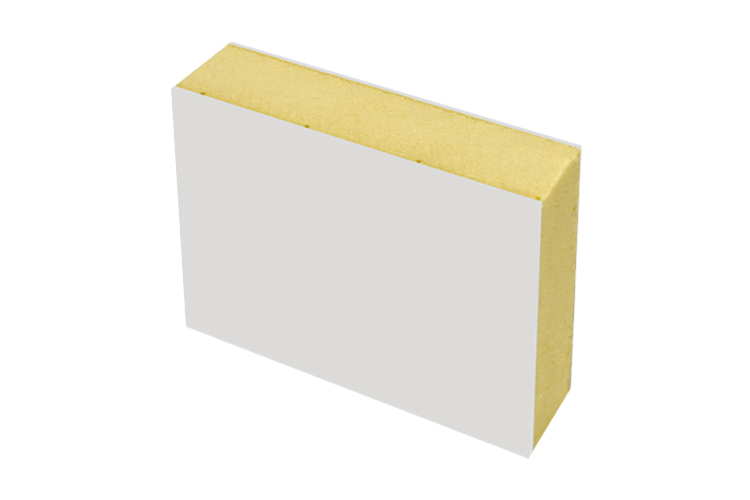

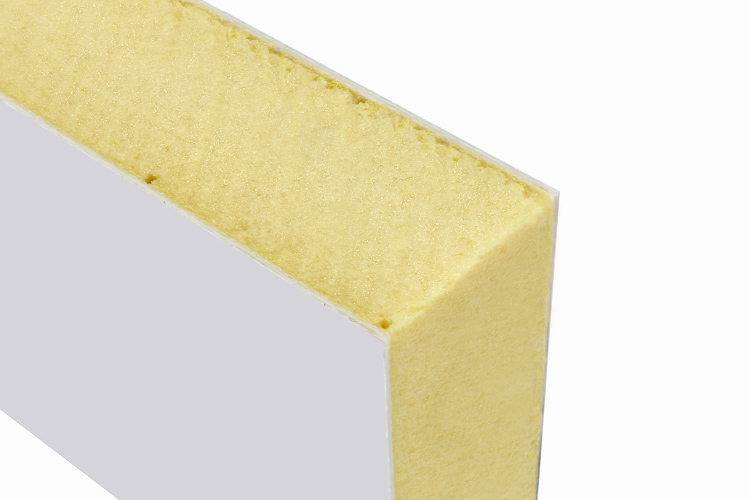

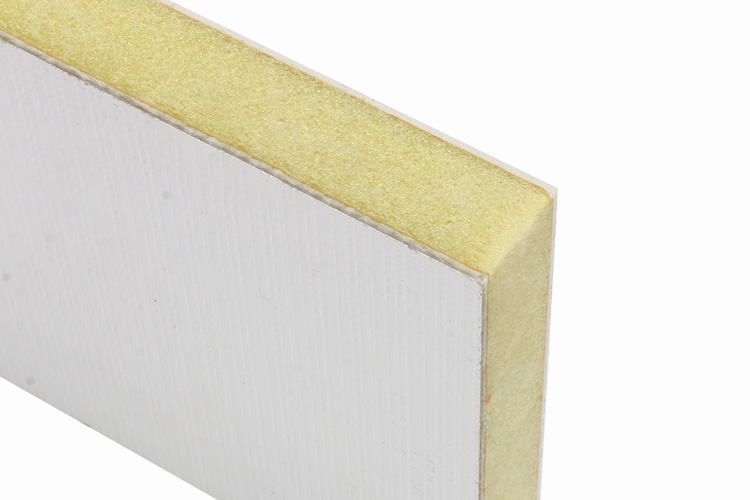

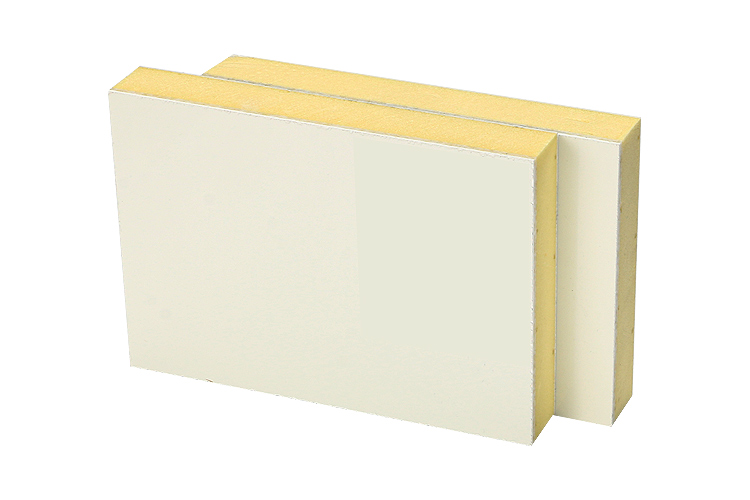

- Upper Skin: 1.2mm CFRT

- Core: XPS Foam

- Lower Skin: 1.2mm CFRT

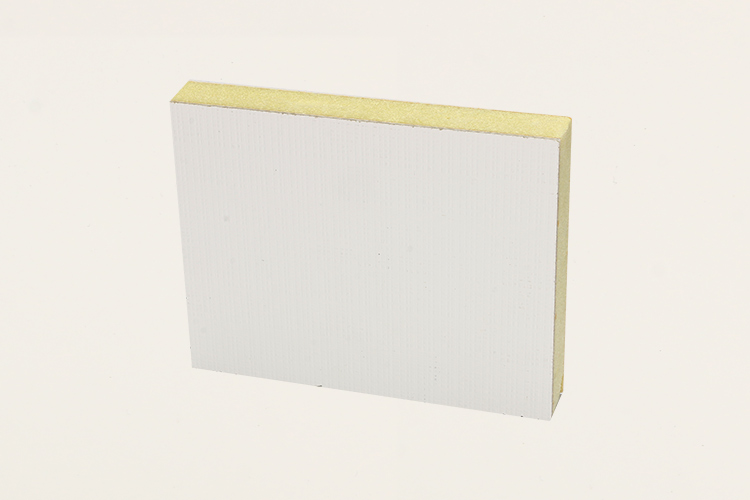

- Color: Matte White

- Foam Density: 35~40kg/m³

40mm CFRT (Continuous Fiber Reinforced Thermoplastic) Facing XPS (Extruded Polystyrene) Foam Sandwich Panel

In the construction of refrigerated trucks, the use of high-performance CFRT-faced XPS sandwich panel materials can effectively improve the thermal insulation performance and structural strength of refrigerated trucks, thereby improving transportation efficiency and saving energy.

CarbodyGroup CFRT facing XPS foam core sandwich panels have excellent thermal insulation performance. Its XPS foam core material has a closed-cell structure, which can effectively isolate heat conduction and reduce energy loss.

CarbodyGroup CFRT facing XPS foam core sandwich panels use CFRT material as the facing layer, which increases the overall structural strength and durability. CFRT is a continuous fiber-reinforced thermoplastic with excellent tensile strength and compressive properties, which can effectively enhance the structural strength of the sandwich panel, making it more durable and stable.

CarbodyGroup CFRT facing XPS foam core sandwich panels has a light weight and excellent processing performance, which is helpful for the manufacturing and assembly process of refrigerated trucks. It can not only reduce the dead weight of the whole vehicle, increase the vehicle’s load capacity and fuel efficiency, but also simplify the production process and improve production efficiency.