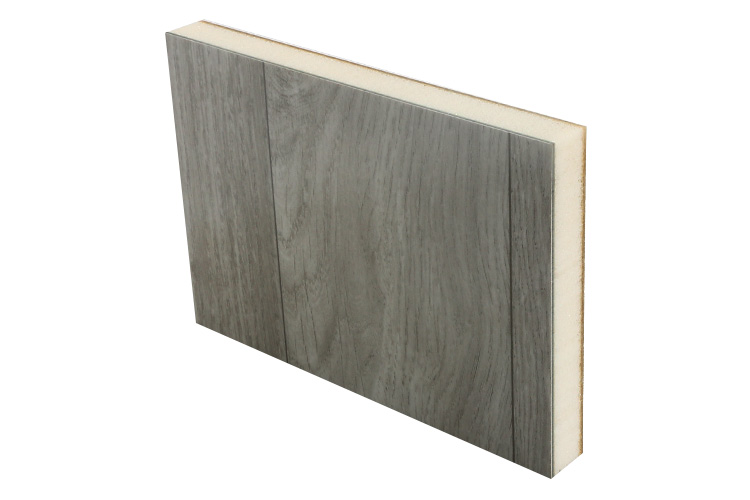

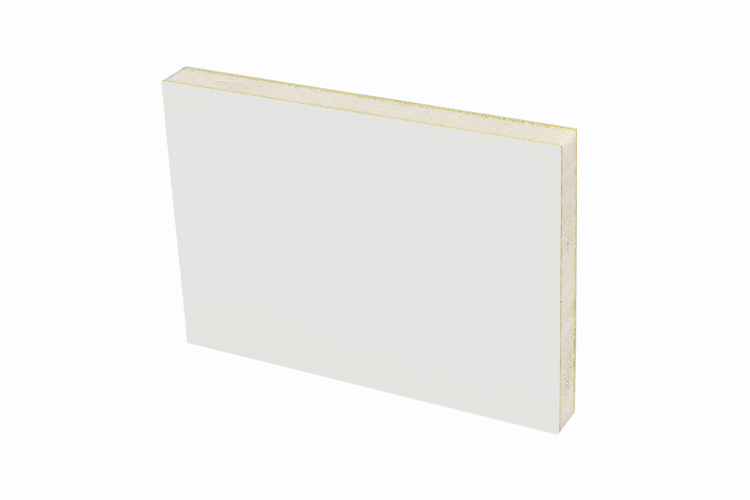

- Total Thickness: 15mm. (Customized)

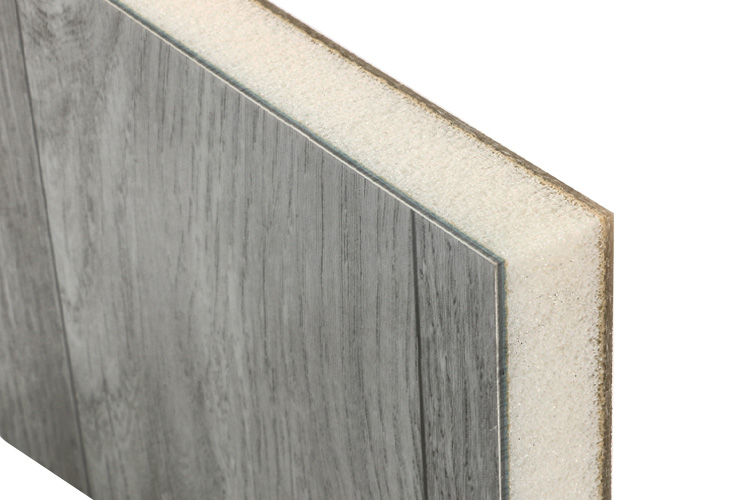

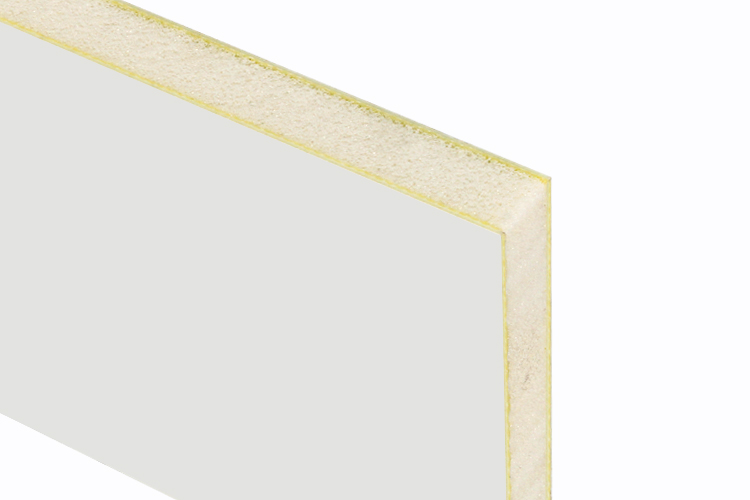

- Face Sheet: 1.2mm Biaxial FRP +45°/-45° with nylon layer vinyl ester resin

- FRP Area Weight: 600g/m²

- Foam Density: 80kg/m³ PET foam

- Area Weight: 5.13kg/m².

- Applications: Yacht deck

FRP skin PET foam sandwich panel is a composite material structure, consisting of two layers of FRP (Fiber Reinforced Plastic, referred to as FRP) skin and PET (polyethylene terephthalate) in the middle Composed of foam core layers.

FRP skin PET foam sandwich panels designed by CarbodyGroup are widely used in yacht construction and are one of the high-quality materials commonly used in modern yacht construction.

Advantages:

Lightweight structure

The deck of the yacht needs to maintain good buoyancy and performance. The FRP skin PET foam sandwich panel is made of lightweight PET foam as the filling layer, which effectively reduces the weight of the overall structure and improves sailing performance and fuel efficiency.

Durability and corrosion resistance

Yachts are in a marine environment and are often exposed to seawater, wind, waves and ultraviolet rays, and are prone to corrosion and fading. Fiberglass provides excellent strength, rigidity and anti-corrosion properties to protect the yacht deck from damage, deformation and seawater erosion.

Customization and design flexibility

CarbodyGroup FRP skin PET foam sandwich panels can be customized according to the yacht’s The design required customization to accommodate deck structures of varying shapes and sizes.