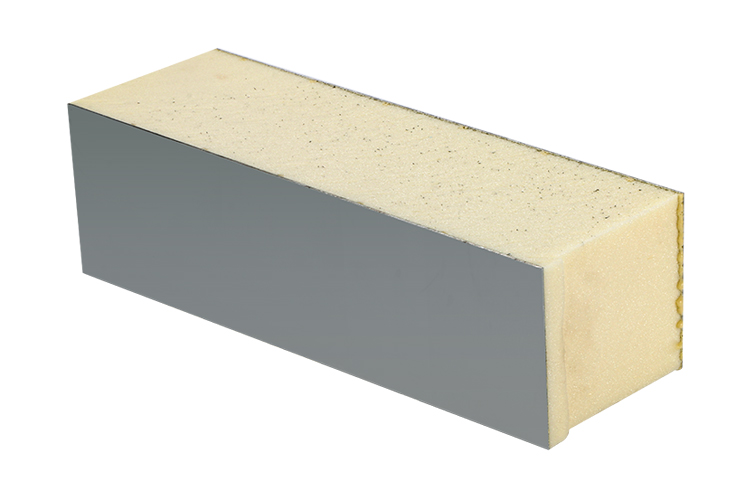

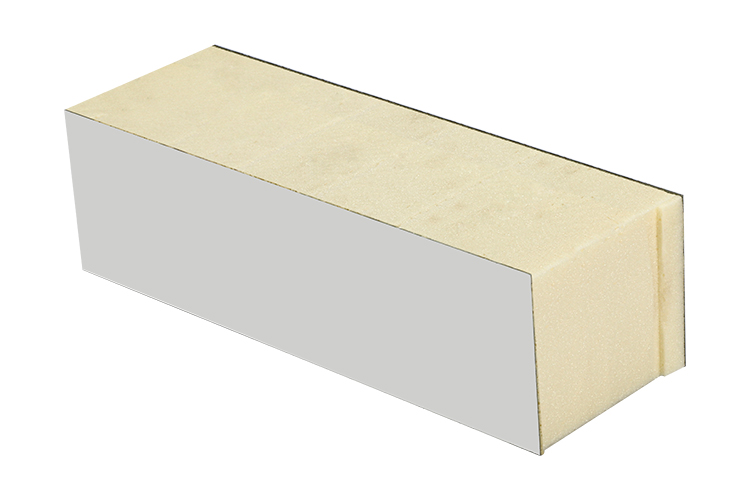

Product Parameters

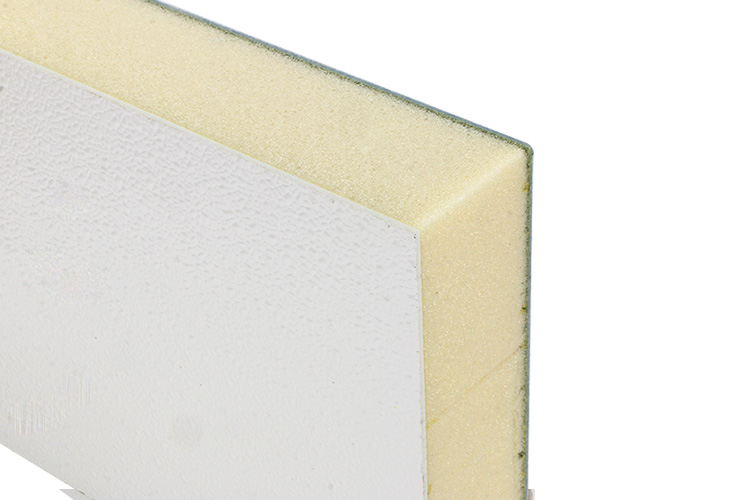

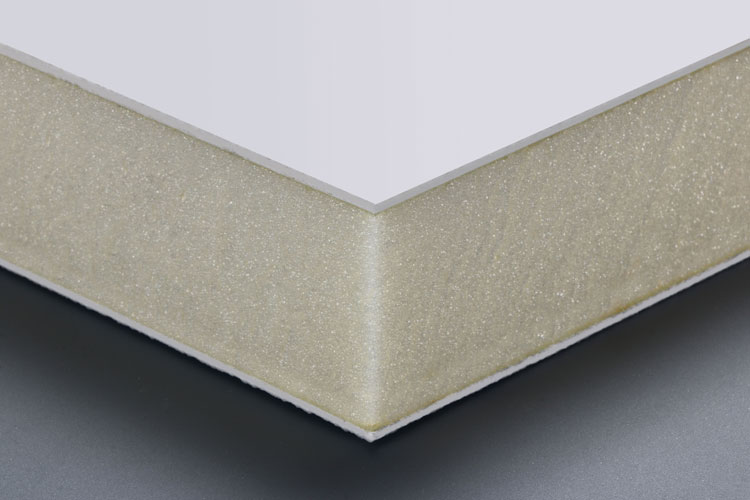

- Thickness: 100.0mm

- Skin Thickness: 0.8

- Core Material: 35kg/m³ Polyurethane foam.

- Skin Material: Galvanized steel sheet.

- Area Weight: 12.8kg/m².

- Applications: Buildings, cold storage, refrigerated trucks.

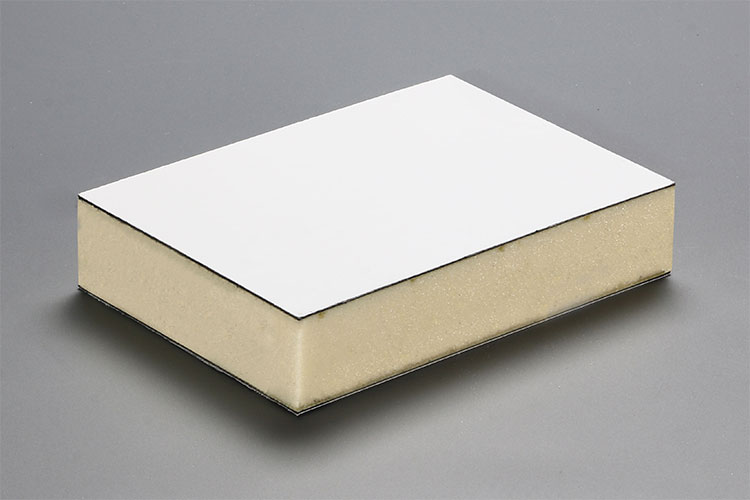

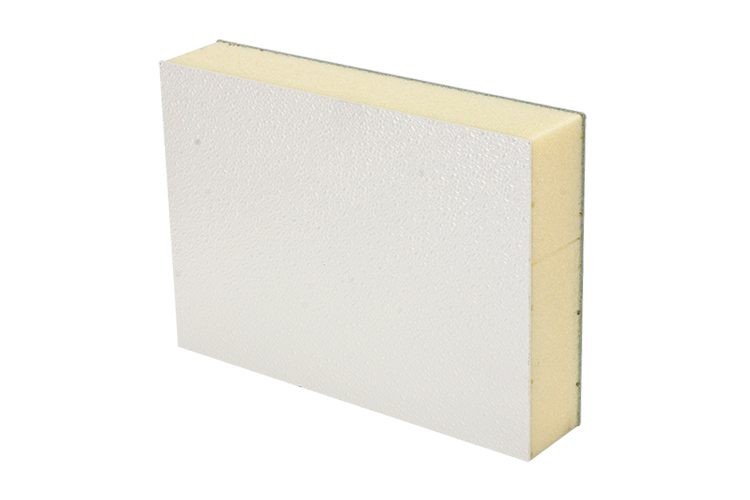

Galvanized steel facing PU foam sandwich panel is a building material usually made of polyurethane (PU) foam filling between two layers of galvanized steel panels.

Advantages

Excellent thermal insulation performance: Polyurethane foam has good thermal insulation properties, which can effectively reduce heat transfer and improve the thermal insulation effect of the building.

Lightweight: PU foam is a lightweight material, making the overall weight of the sandwich panel lighter and easier to handle and install.

High strength: Galvanized steel plate provides good structural strength, making the sandwich panel have high compressive resistance and bending resistance.

Corrosion resistance: Galvanized steel plate has good corrosion resistance, extending the service life of the sandwich panel.

Easy installation: Sandwich panels can be assembled directly without additional waterproofing, saving construction time and costs.

Beautiful appearance: Galvanized steel panels are available in various colors and surface treatments, making the sandwich panel more beautiful in appearance.

Applications

Industrial plant construction: used for walls, roofs and thermal insulation devices of industrial plants to improve the thermal insulation performance and structural strength of the building.

Cold storage and refrigerated trucks: Due to its excellent insulation properties, it is often used in the construction of cold storage and refrigerated trucks to keep the internal temperature stable.

Office buildings and commercial buildings: Used for exterior wall decoration of office buildings and commercial buildings, providing good thermal insulation effect while beautifying the appearance of the building.

Residential construction: Used in residential construction for wall insulation to improve indoor comfort.