What is a Fiberglass Sheet?

Fiberglass Sheet (thermosetting glass fiber reinforced plastic) combines glass fiber and thermosetting resin, with a gel-coated surface. As a new environmentally friendly material, it offers greater toughness than steel and aluminum products. It resists cracking, deformation, and heat transfer even under extremely low or high temperatures. As a result, many industries widely use FRP, including dry truck bodies, wall decorative covers, refrigerated truck bodies, RV side panels, and cold storage walls.

Advantages

- Extremely lightweight: The relative density is usually between 1.5 and 2.0, which is only 1/4 to 1/5 of carbon steel.

- Extremely strong: The tensile strength of glass fiber is close to that of carbon steel.

- Corrosion resistance: Glass fiber can resist corrosion from a variety of chemical media, including acids, alkalis, salts and most chemicals.

- Electrical insulation: Glass fiber has good electrical insulation properties and is suitable for use as an insulating material.

- Thermal insulation: FRP transfers heat slowly, which gives it significant advantages in places that require heat preservation or insulation, such as cold storage, storage tanks, HVAC equipment, etc. FRP has a low thermal conductivity of 1.25~1.67kJ/(m·h·K) at room temperature, which is only 1/100~1/1000 of metal and is an excellent thermal insulation material.

- Aesthetics: FRP sheets can be made of anti-aging, weather-resistant, and UV-resistant gel-coated resins, with a smooth and beautiful surface and bright color.

- Easy to process: FRP sheets offer excellent plasticity and processability, allowing you to shape them into various products of different sizes through molding, injection molding, and manual processes.

- Eco-friendly: FRP sheets do not contain volatile and corrosive substances and are a recyclable product.

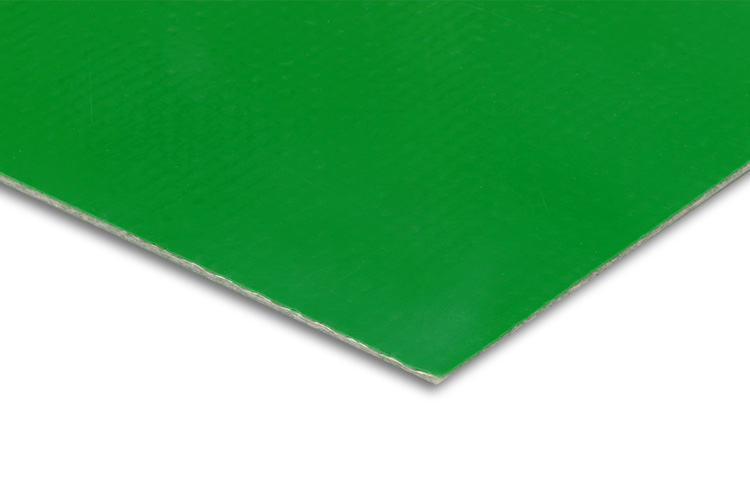

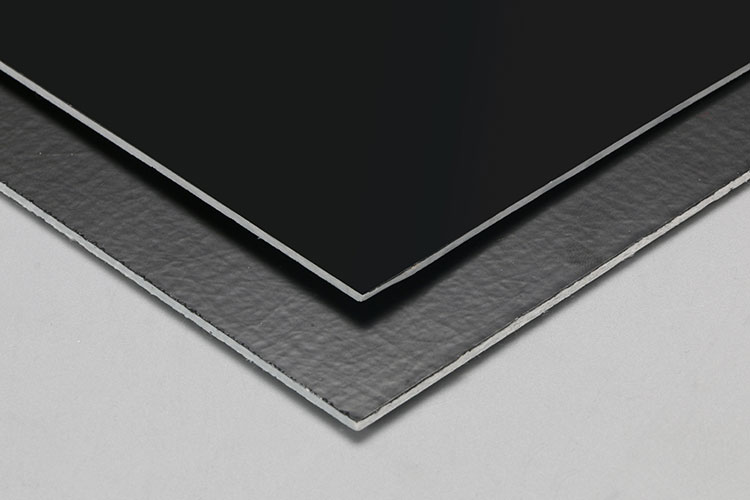

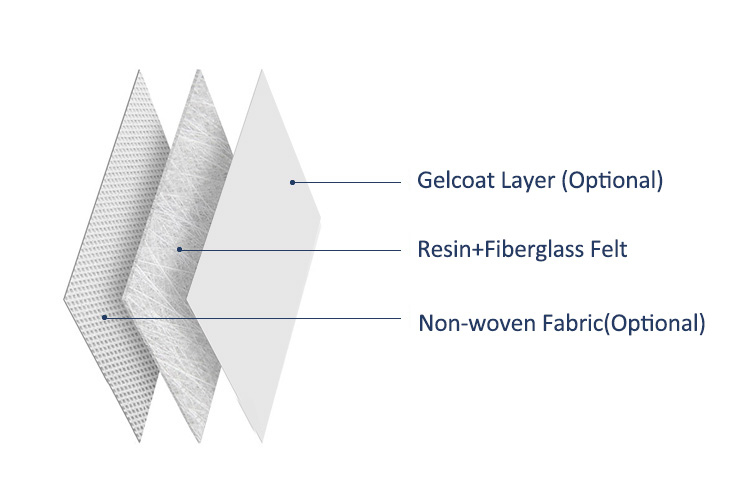

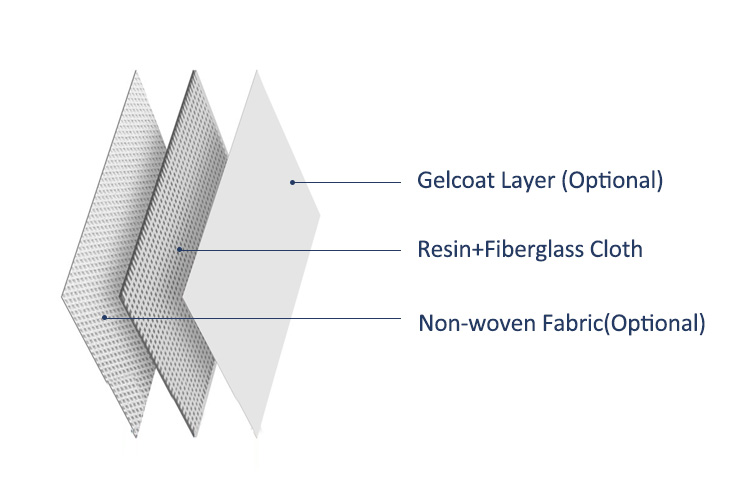

Fiberglass Sheet Structure

| Gelcoat Layer | Gelcoat is a protective surface coating that provides a smooth, shiny finish to FRP surfaces, making them more aesthetically pleasing |

| Fiberglass Reinforcement Layer | High-quality thermosetting resin + fiberglass felt or fiberglass cloth |

| Non-woven Fabric Layer | The non-woven fabric serves as a connecting layer, and FRP and other materials can be tightly bonded by spraying glue. |

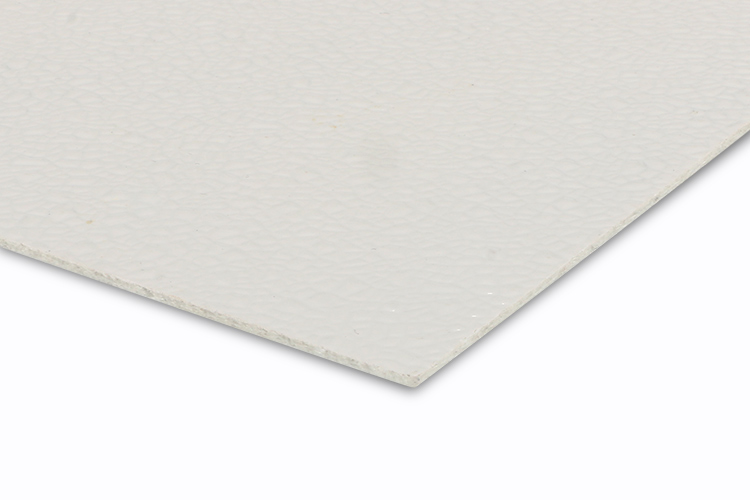

Felt-based Fiberglass sheet

Resin+Fiberglass mat: Chopped fiber, continuous fiber mat, stitched mat, etc.

Advantages: Smooth surface, lower cost.

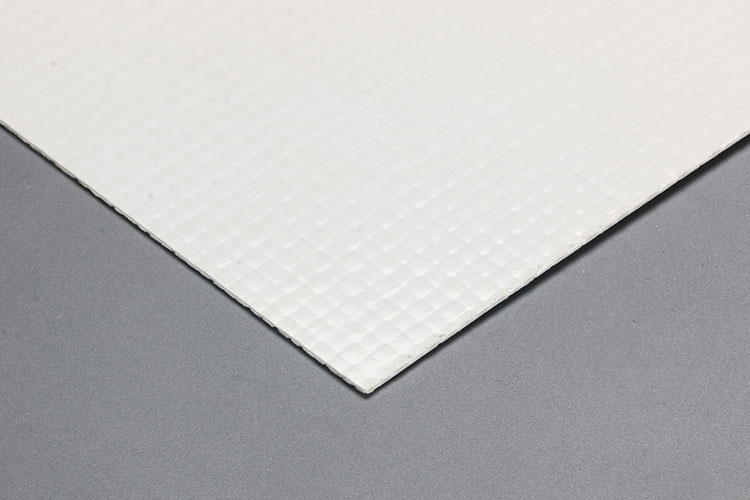

Cloth-based Fiberglass Sheet

Resin+Fiberglass cloth: Mesh cloth, square cloth, plain cloth, axial cloth, etc.

Advantages: High strength and stable performance.

Fiberglass Sheet Features

- High mechanical strength and good impact toughness

- Easy to clean

- Corrosion-resistant and wear-resistant

- Resistant to yellowing and aging

- High-temperature resistance

- No deformation, low thermal conductivity

- Excellent insulation properties

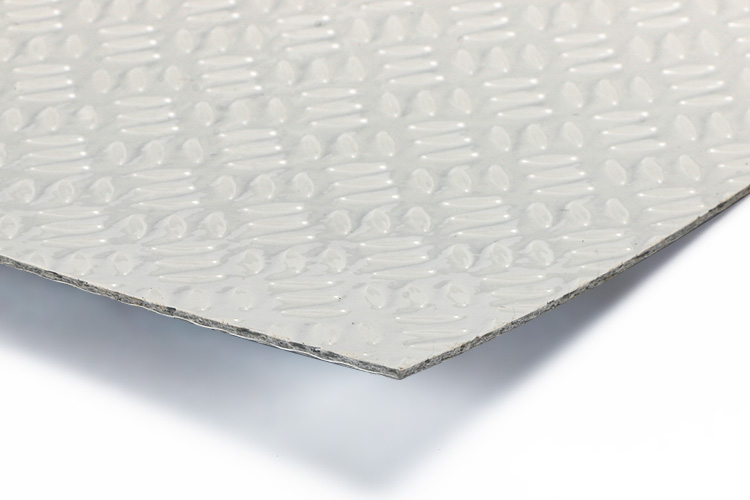

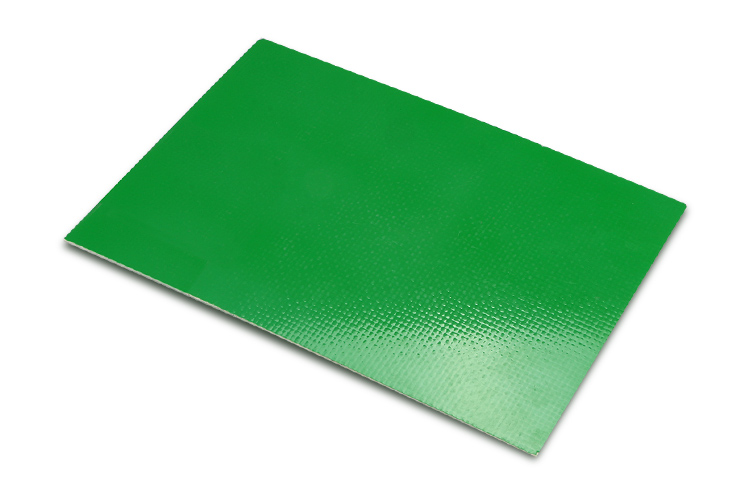

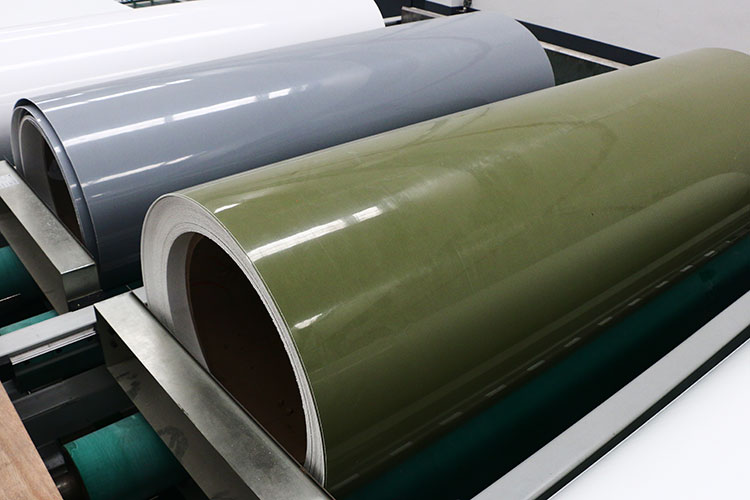

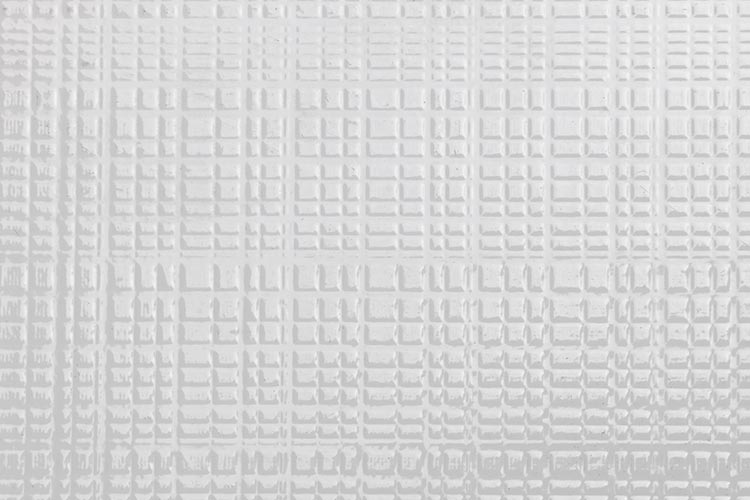

Fiberglass Sheet Samples

FRP Panels with Various Surface Treatments Available

We offer gel-coated flat FRP panels in glossy, matte, stone grain, woven, bubble, and faux leather surface patterns. If you need other patterns, please send us samples or detailed files.

.jpg)