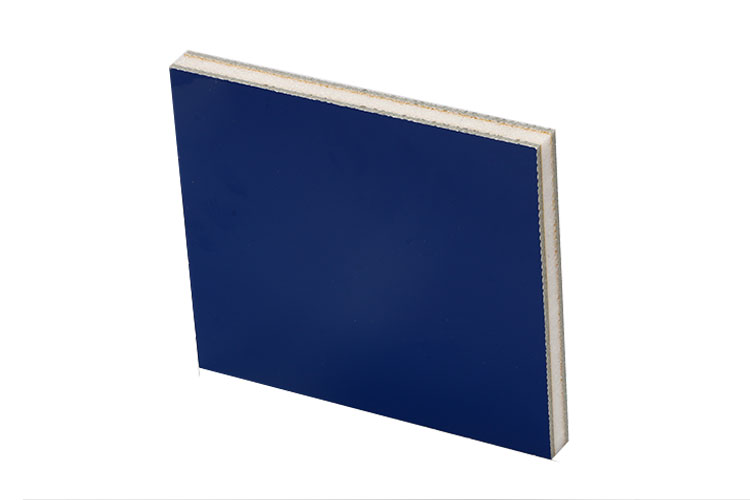

ACP facing foam sandwich panel is a new composite material widely used in the construction and industrial fields. It combines the benefits of aluminum composite panels and rigid foam. It has thermal insulation and thermal insulation properties. This material has become one of the preferred materials in modern architectural decoration and industrial design due to its excellent features such as lightweight, high strength, and corrosion resistance.

Structural Diagram of ACP Foam Sandwich Panel

ACP (Aluminum Composite Panel) is a multi-layered material consisting of a polyethylene core between two layers of aluminum sheets. It offers light weight, strength, high decorative appeal, and ease of processing.

- Surface layer (ACP layer): The surface of ACP offers customization with a wide range of colors and patterns, enhancing its decorative appeal.

- Core layer (foam layer): The core layer consists of rigid foam materials known for their high compressive strength, typically including Extruded Polystyrene Foam (XPS), Polyethylene Terephthalate (PET), Polyurethane Foam (PU), Polyvinyl Chloride Foam (PVC), and other similar materials.

Features

ACP Foam Sandwich Panels Offer Many Unique Benefits

- Lightweight and high strength: Due to the use of foam core, ACP facing foam sandwich panels are much lighter than traditional building materials, making them easier to transport and install. The outer and bottom layer materials give them high strength and can withstand external pressure and impact.

- Thermal Insulation: The foam core has an extremely low thermal conductivity, which effectively blocks external heat.

- Weather resistance: The ACP surface layer has received special treatment and thus has good corrosion resistance and weather resistance. It can be exposed to sunlight, rain and other natural environments for a long time without deformation or fading.

- Aesthetics: ACP foam sandwich panels offer customization of surface colors and patterns to align with specific design requirements.

Specifications

| Skin material | Aluminum Composite Panels |

| Core material | XPS/PET/PU/PU/PVC foam |

| Length | 2440mm |

| Width | 1220mm |

| Total Thickness | 5.0~120mm |