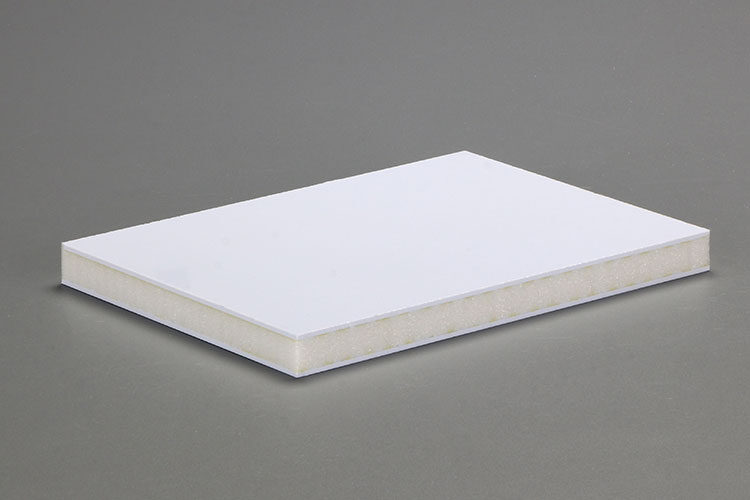

- Total Thickness: 15.0mm.

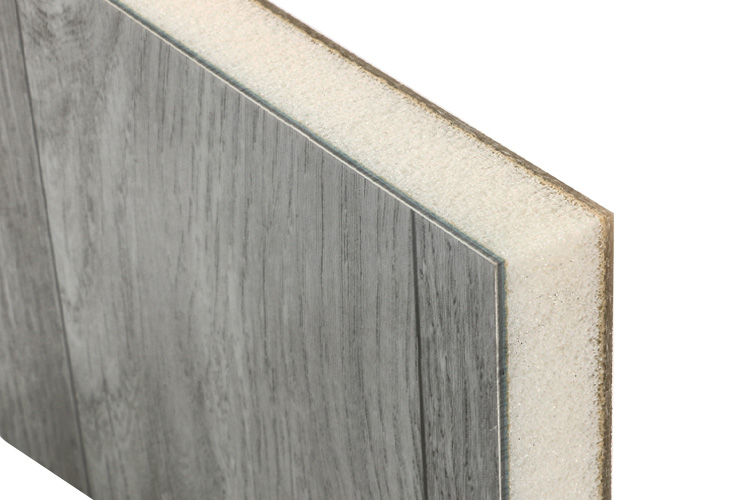

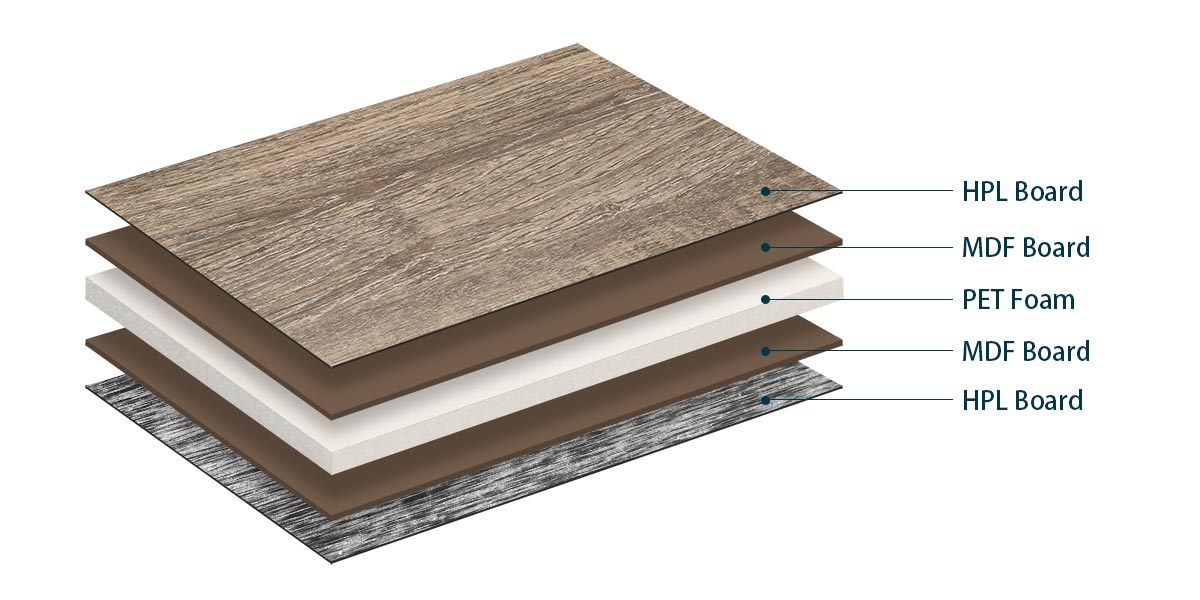

- Skin: 1mm HPL + 3mm MDF wood

- Core Material: PET foam

- Foam Thickness: 7mm

- Foam Density: 100kg/m³ PET foam.

- Area Weight: 9.78kg/m².

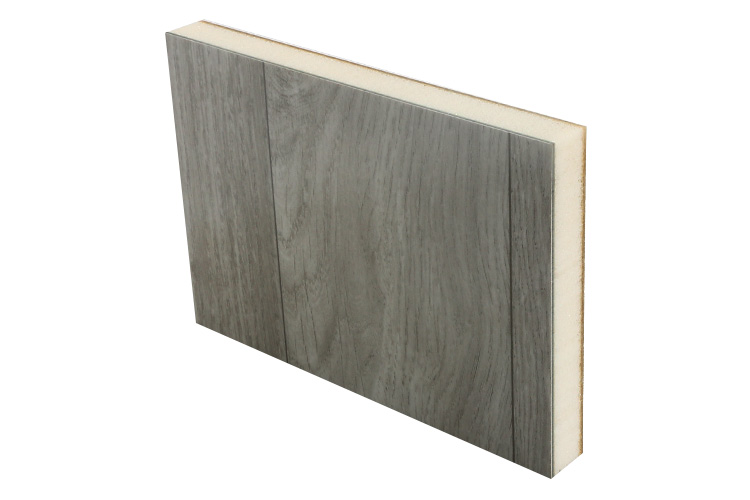

- Surface Treatment: Customizable wood grain pattern or color.

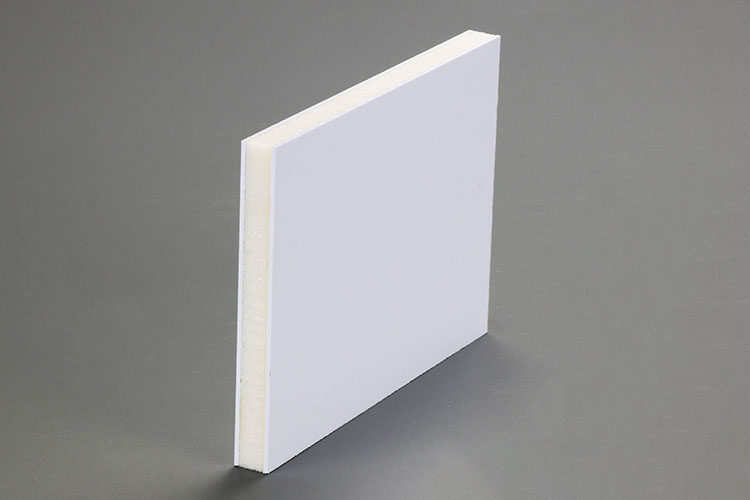

- HPL Board: The HPL (High-Pressure Laminate) board is a high-pressure laminate with many advantages such as water resistance, fire resistance, and antibacterial. Its surface color and texture are rich and colorful, making it widely used in fields such as construction and furniture manufacturing.

- MDF Board: MDF (Medium Density Fiberboard) board is a kind of artificial wood pressed by wood fiber and glue. It has uniform density and smooth surface and is widely used in furniture manufacturing, interior decoration, packaging and other fields.

- PET Foam: Rigid PET foam has higher density and hardness, which makes it perform better in situations where better structural support is required, making it widely used as the core material of composite panels.

Product Advantages

- High strength.

- Waterproof.

- Scratch resistant.

- Easy to cut.

- High nail-gripping power.

- Aesthetic effect.

Applications

Furniture for interiors of RVs, mobile homes, hotels, hotels, villas, offices, etc.

HPL Pattern

We offer a variety of surface colors and patterns, and you can customize your own style.